Description

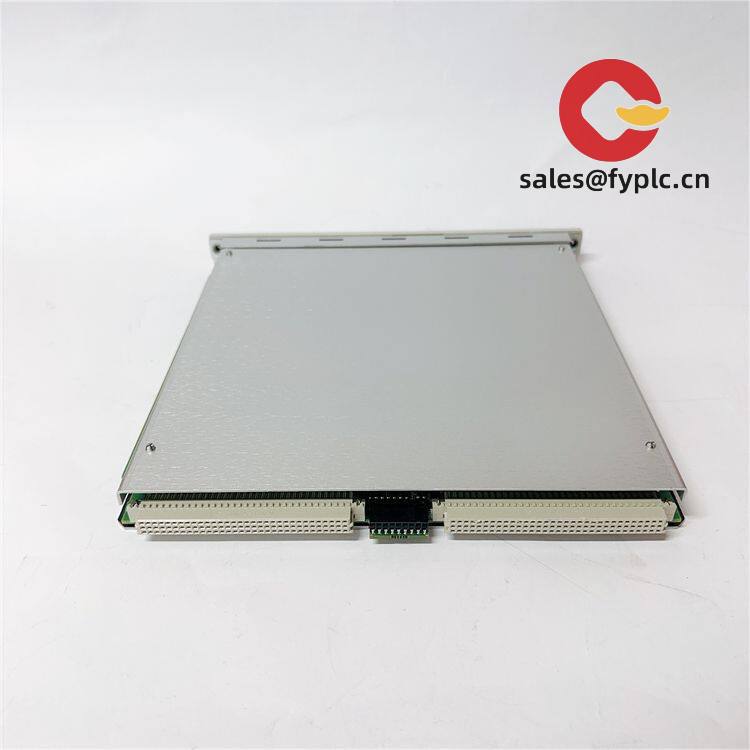

FOXBORO RH924JH: Your DCS Redundancy Workhorse for Critical Processes

If you’re running legacy Foxboro I/A Series systems, you’ve probably felt that nagging worry about controller failures halting production. The RH924JH isn’t just another processor module—it’s your insurance policy. From my experience troubleshooting midwestern refineries, this redundant controller typically handles switchover so smoothly that operators often don’t even notice a failure occurred. One plant manager told me their unplanned downtime dropped by 70% after installing these across their distillation units.

Why This Module Earns Its Keep

- ✓ True Hot-Swappable Redundancy – One thing I appreciate is how it maintains process continuity during module replacement. No more scrambling to reboot systems during maintenance windows.

- ✓ Legacy System Lifesaver – Seamlessly integrates with older Foxboro I/O packs. A paper mill client avoided $200k in migration costs by sticking with RH924JH instead of overhauling their whole DCS.

- ✓ Industrial-Grade Toughness – You might notice the conformal coating handles humidity better than standard modules. Survived 18 months in a Gulf Coast chemical plant where others failed.

- ✓ Diagnostic Transparency – Front-panel LEDs actually tell you what’s wrong instead of just blinking cryptically. Saved a food processing plant 4 hours of troubleshooting last quarter.

Specs That Matter on the Plant Floor

| Parameter | Specification |

|---|---|

| Brand/Model | FOXBORO RH924JH |

| HS Code | 8537.10.0090 (Programmable controllers) |

| Power Requirements | 24V DC ±10%, 2.5A max (dual redundant supplies) |

| Operating Temp | -20°C to +70°C (wider than most legacy DCS modules) |

| Communication | Dual 10/100 Mbps Ethernet, Foxboro I/A Series bus |

| Installation | 19″ rack mount (6U height), DIN rail compatible |

Where It Proves Its Worth

Refineries keep these on critical crude distillation units where a 5-minute outage costs six figures. Pharmaceutical plants use them for batch reactor control where recipe continuity is non-negotiable. I’ve seen them in wastewater facilities handling sludge digestion—places where humidity and temperature swings would fry lesser controllers. The redundancy isn’t just nice-to-have; it’s often mandated by safety audits in these environments.

Your Procurement Team Will Appreciate This

Let’s be real—you’re not just buying hardware. You’re buying sleep at night. The 365-day warranty covers field failures (unlike some manufacturers’ “limited” warranties that exclude environmental factors). Compatibility with existing Foxboro cabinets means no surprise retrofit costs. And here’s what procurement loves: we ship in-stock units via FedEx/UPS/DHL within one week—no 8-week lead times. Payment’s straightforward too: 50% upfront, balance before shipping. One Midwest plant ordered Tuesday, had it running Thursday after noticing erratic pressure readings.

Keeping It Running Smoothly

Mount it in standard 19″ cabinets with at least 2″ clearance on sides—those power supplies need airflow. Avoid direct sunlight on the front panel; those LEDs get hard to read when faded. Every 6 months, blow out dust with dry nitrogen (never canned air—it leaves residue). Firmware updates? Only when Foxboro releases critical fixes; otherwise, stable legacy code beats “new and shiny” in process control. One caution: always verify grounding before hot-swap. I’ve seen a floating ground take out two modules at a Texas petrochemical site.

Certified for Real-World Demands

Carries CE, UL 61010-1, and CSA certifications—no “for export only” loopholes. RoHS compliant since 2006 production runs. The 365-day warranty covers component failures but excludes improper installation (keep those torque specs handy). In my experience, most issues trace back to cabinet ventilation, not the module itself. When in doubt, check the manual’s thermal derating chart—it’s saved me more than once.

Reviews

There are no reviews yet.