Description

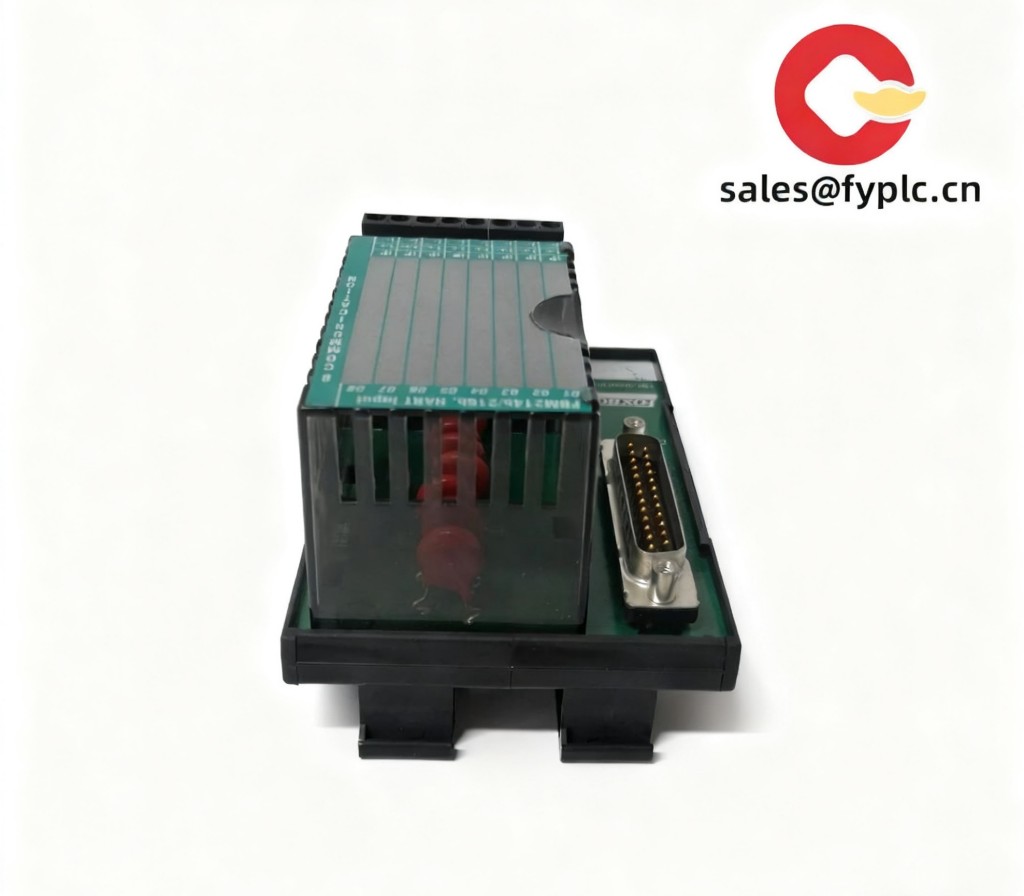

FOXBORO RH924WA Fiber Optic Network Adapter – Reliable Fiber Link for I/A Series and Plant Ethernet Segments

The FOXBORO RH924WA is a fiber optic network adapter designed to extend and harden control-network connectivity in industrial environments. From my experience, it’s typically used to bridge cabinets or buildings where long runs and EMI make copper a liability. You might notice that plants running drives or high-power switching tend to migrate to fiber on critical DCS segments—this module makes that step straightforward while staying aligned with Foxboro control architectures.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Industrial fiber link for Foxboro networks – Provides a robust optical connection for I/A Series DCS segments where copper isn’t practical.

- EMI immunity and long-distance runs – Fiber typically shrugs off electrical noise and enables longer spans across large facilities.

- Designed for cabinet deployment – Compact module form that fits well in control panels with clean cable routing.

- Ethernet compatibility – Works within standard IEEE 802.3 Ethernet environments used alongside Foxboro controllers and switches.

- Safer plant networking – Optical isolation reduces ground loop issues and transient risks on critical control networks.

- Supports redundant architectures – Suitable for dual-path designs to enhance network availability, which many plants prefer for CCR links.

Technical Specifications

| Brand / Model | FOXBORO RH924WA |

| Product Type | Fiber Optic Network Adapter (industrial) |

| HS Code | 8517.62 (data transmission apparatus) |

| Power Requirements | 24 VDC nominal, typical consumption < 10 W |

| Operating Temperature | 0 to 60 °C, non-condensing environment recommended |

| Signal I/O Types | Network data over fiber optic; electrical Ethernet for local coupling (where applicable) |

| Communication Interfaces | IEEE 802.3 Ethernet; fiber optic port (commonly 100BASE‑FX); may be paired with 10/100BASE‑TX |

| Fiber Type | Multimode or single-mode (project-dependent); SC or ST connectors are typical in many cases |

| Installation Method | Cabinet mounting (DIN-rail/panel); fiber patch routing with proper bend radius and strain relief |

Note: Interface details (connector type and specific link speed) can vary by sub-variant and network design. We typically verify against the site’s Foxboro DCS topology before shipment.

Application Fields

- Process plants using FOXBORO I/A Series or EcoStruxure Foxboro DCS segments that require fiber backbones between cabinets or buildings.

- Areas with heavy EMI, VFDs, or high-current equipment where copper Ethernet is unreliable.

- Long-haul control room to remote I/O marshalling panels, utility corridors, and substation links.

- Oil & gas, refining, chemicals, pharmaceuticals, power generation, water/wastewater—where deterministic and resilient networking is valued.

Advantages & Value

- Reliability under noise – Fiber optic links typically perform better around high-energy equipment and long cable trays.

- Compatibility with Foxboro architectures – Designed to sit comfortably in Foxboro network topologies without awkward workarounds.

- Lifecycle confidence – Industrial-grade design with straightforward replacement and spares strategy.

- Cost control – In many cases, shifting critical legs to fiber reduces downtime from transient faults on copper.

- Support – We can help verify fiber type (single-mode vs. multimode), connector standard, and path redundancy before you place the order.

Installation & Maintenance

- Cabinet environment – Install in a ventilated control cabinet; maintain ambient 0–60 °C and avoid condensation.

- Power and grounding – Supply stable 24 VDC; maintain proper cabinet grounding to minimize common-mode noise.

- Fiber handling – Respect bend radius, use quality patch cords, and clean connectors (lint-free wipes and appropriate solvent).

- Redundancy – Where the DCS design allows, run dual fiber paths in separate routes to improve availability.

- Wiring checks – Verify Tx/Rx polarity, connector type (SC/ST), and fiber type (MM/SM) to match plant standards.

- Routine maintenance – Periodic port inspection, connector cleaning, and logging link stats; apply firmware updates if the installed variant supports them.

Quality & Certifications

- Manufacturer-built to industrial standards; CE compliant in typical deployments

- UL/CSA conformity expected for control-cabinet installation

- RoHS alignment for restricted substances

- Backed by a 365-day warranty from shipment

Suggested Complementary Items

- Industrial fiber patch cords (SC–SC or ST–ST; 62.5/125 µm multimode or OS2 single‑mode depending on site spec)

- DIN-rail fiber management trays and labeled bulkhead adapters for clean routing

- Industrial Ethernet switches with fiber uplinks for ring or redundant star topologies

Reviews

There are no reviews yet.