Description

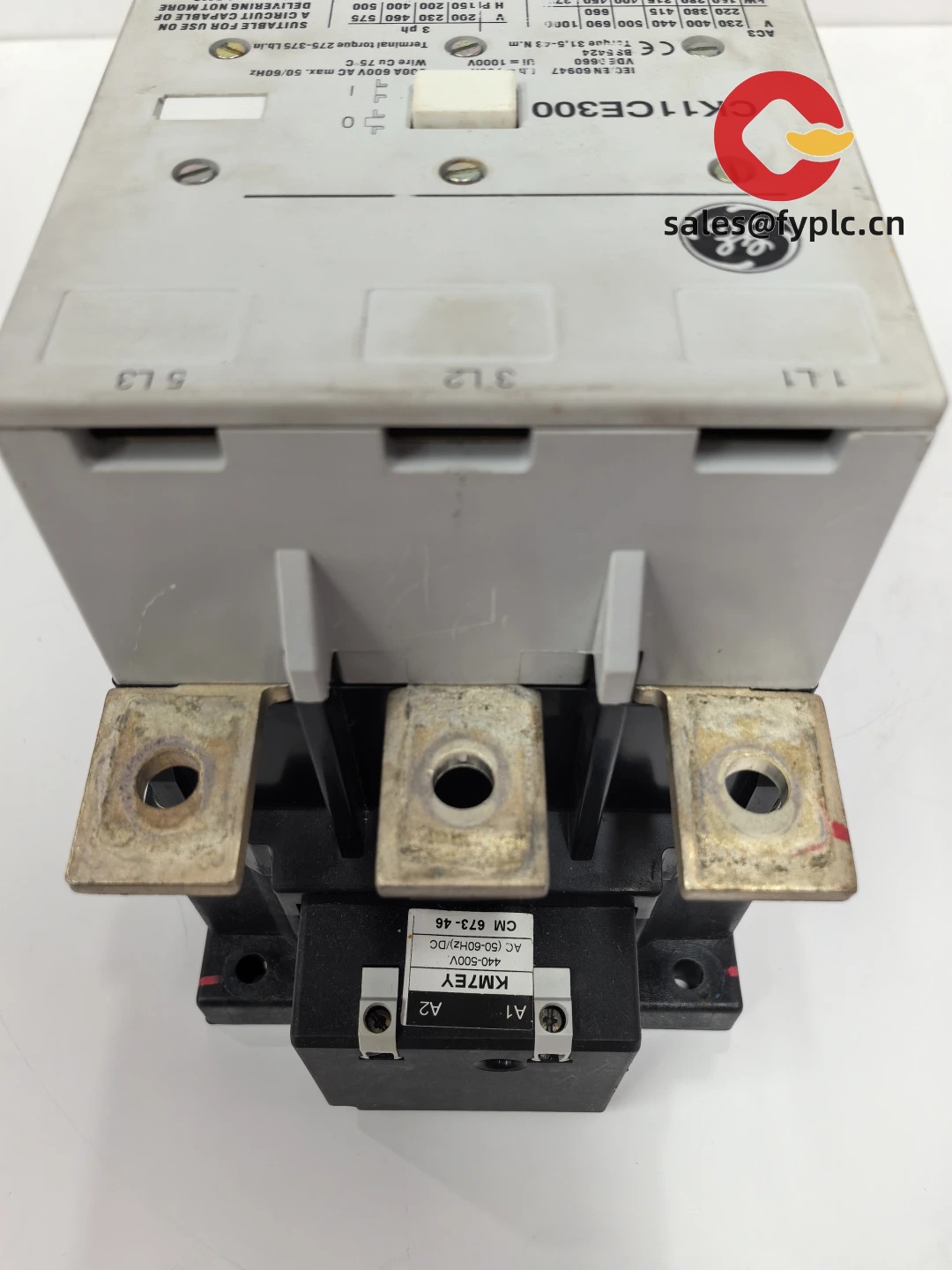

GE CK11CE300 – Replacement Assembly for CK/CL Series Contactors in Motor Control Panels

From my experience, the GE CK11CE300 is commonly referenced as an OEM replacement assembly used to refurbish GE CK/CL series low-voltage contactors in motor starters and MCC buckets. Plants typically use it when they need to restore reliable switching on 3‑pole power circuits without changing the entire contactor. You might notice that it’s favored in maintenance programs where downtime is the bigger cost than the part itself.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: Typically 1 week for in-stock items; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- OEM fit for GE CK/CL frames – Designed to drop into the CK11 frame family, preserving the original mechanical envelope and mounting points.

- Service-life restoration – Replacing worn contact components typically restores normal switching performance and reduces nuisance trips or heat buildup.

- Consistent electrical interface – Keeps the existing power and control wiring layout in place, minimizing rewiring time on site.

- Supports preventive maintenance plans – Ideal for scheduled overhauls in MCCs, compressors, pumps, and conveyors where a full changeout isn’t necessary.

- Compatibility-minded – In many cases, maintains the UL/CE status of the parent device when serviced with OEM parts (verify against your nameplate and procedures).

- Reduced downtime – Faster than swapping the entire contactor, especially in tight panels or legacy cabinets.

Technical Specifications

| Brand / Model | GE CK11CE300 |

| Product Type | Replacement assembly for GE CK/CL series contactor (CK11 frame). Verify against the parent contactor nameplate. |

| HS Code | 8538.90 (Parts suitable for apparatus of headings 8535/8536/8537) |

| Power Requirements | Not powered by itself; follows the coil rating of the parent contactor (e.g., 24 VDC or 110–120 VAC variants depending on the installed coil). |

| Dimensions & Weight | Matches the CK11 frame envelope. Refer to the parent contactor’s mechanical drawing for exact values. |

| Operating Temperature | Typically −20°C to +60°C when installed in a ventilated enclosure per manufacturer guidance. |

| Signal Input/Output Types | 3 main power poles (normally open) as part of the contactor assembly; auxiliary contacts as fitted to the parent device. |

| Communication Interfaces | N/A (mechanical contact assembly; no communications). |

| Installation Method | Field replacement within the CK11 contactor housing; panel or backplate mounting per the original contactor installation. |

Application Fields

You’ll typically find this type of replacement used in low-voltage motor control circuits across:

- Motor control centers (MCC) for pumps, fans, and compressors

- Conveyor lines and packaging equipment in discrete manufacturing

- HVAC plant rooms and building services panels

- Water/wastewater lift stations and treatment skids

- Cement, mining, and metals operations where contact wear is a routine maintenance item

A maintenance lead from a cement plant told me they keep two CK11 assemblies on the shelf because a planned swap takes under an hour and avoids a full contactor changeout during peak production.

Advantages & Value

- Reliability: Restores proper contact pressure and surface condition, which in many cases lowers operating temperature under load.

- Compatibility: Preserves wiring and footprint; no panel rework in most installations.

- Cost Control: Significantly lower total cost than replacing the complete contactor, especially in legacy MCC compartments.

- Support: We can help verify fit against your contactor nameplate and coil voltage before shipment.

Installation & Maintenance

- Environment: Install in a clean, dry control cabinet with adequate ventilation; follow your enclosure’s IP/NEMA rating requirements.

- Safety: Isolate and lock out/tag out all power sources. Discharge stored energy and verify absence of voltage before disassembly.

- Wiring: Reuse original lugs and bus connections where possible; torque to spec and check phase spacing/creepage clearances.

- Alignment: After replacement, confirm uniform contact wipe and spring action. Replace auxiliary blocks or arc chutes if worn.

- Routine care: Inspect contact surfaces during shutdowns for pitting; clean with approved non-residue cleaner. Check coil voltage against nameplate and monitor heat rise during initial run.

- Firmware/Settings: Not applicable for mechanical assemblies; any protection settings remain in the upstream overload relay/relay device.

Quality & Certifications

- Standards: Typically used to maintain the original UL and CE conformity of the parent GE contactor when serviced with OEM parts.

- RoHS: Parts are generally RoHS-compliant for low-voltage control gear.

- Warranty: 365-day warranty from shipment date.

Note: CK11CE300 designations may be specific to certain CK/CL contactor frames or kits. For a precise match, please share the parent contactor catalog number, coil voltage, and any auxiliary block configuration. That quick check tends to prevent surprises during installation.

Reviews

There are no reviews yet.