Description

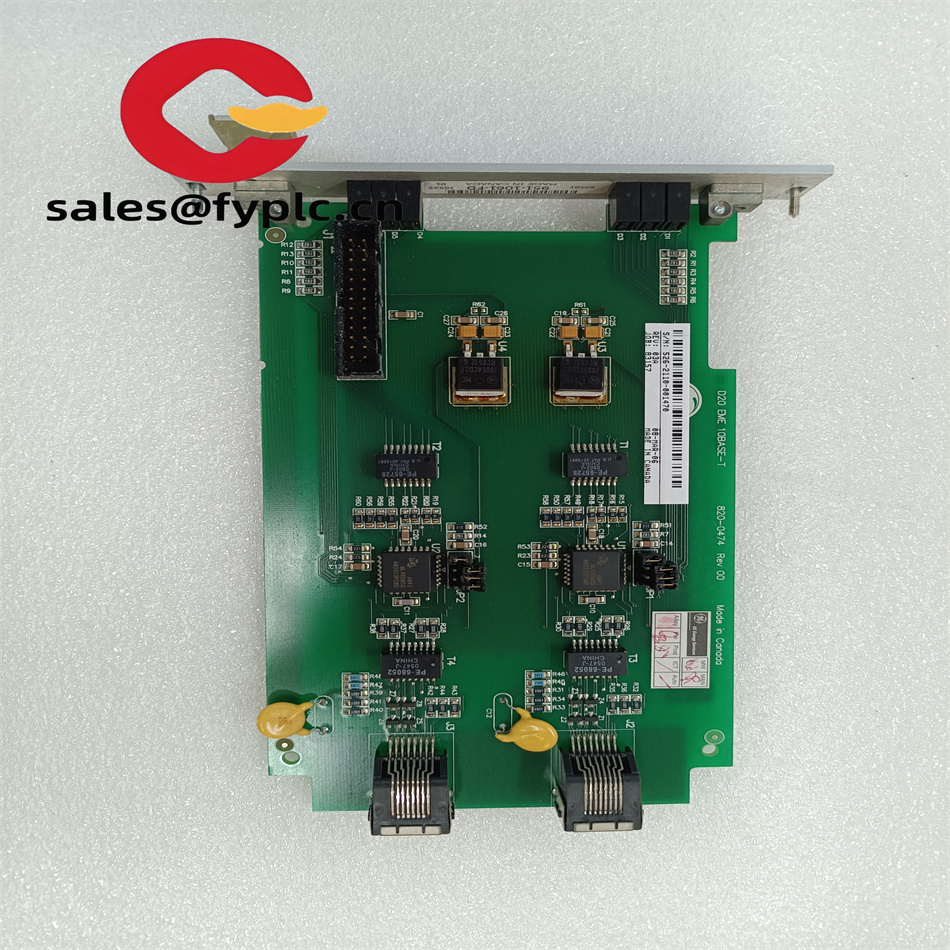

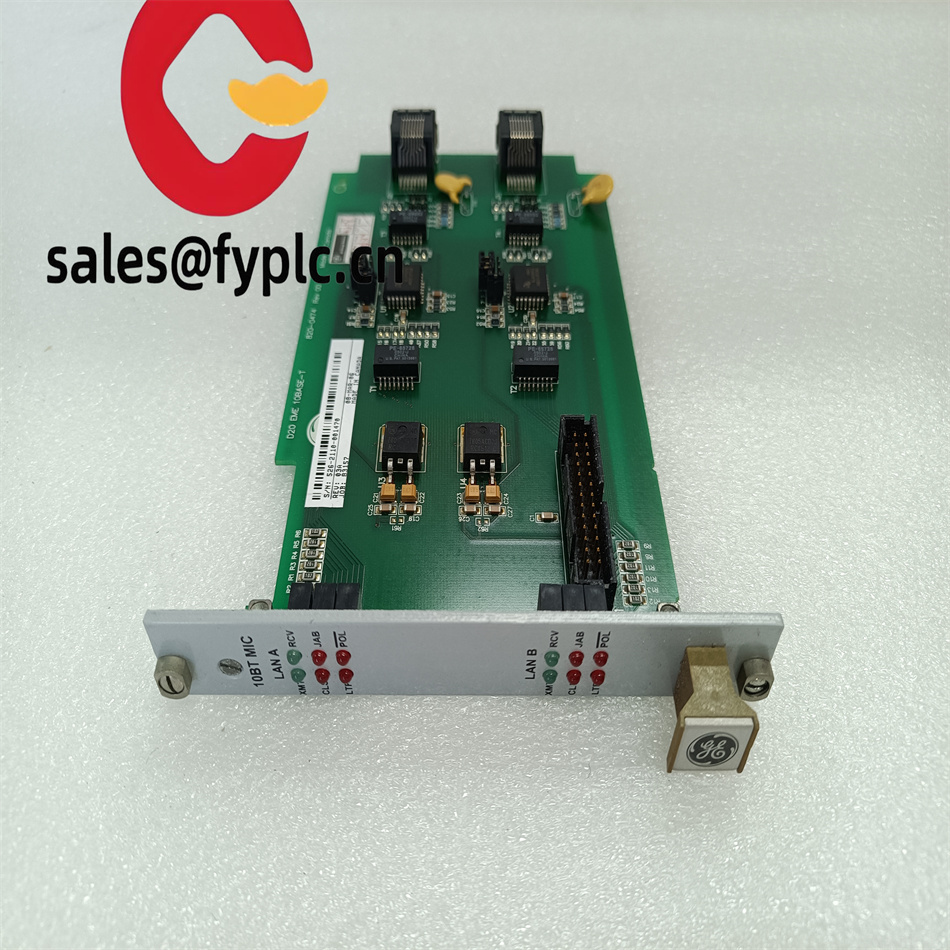

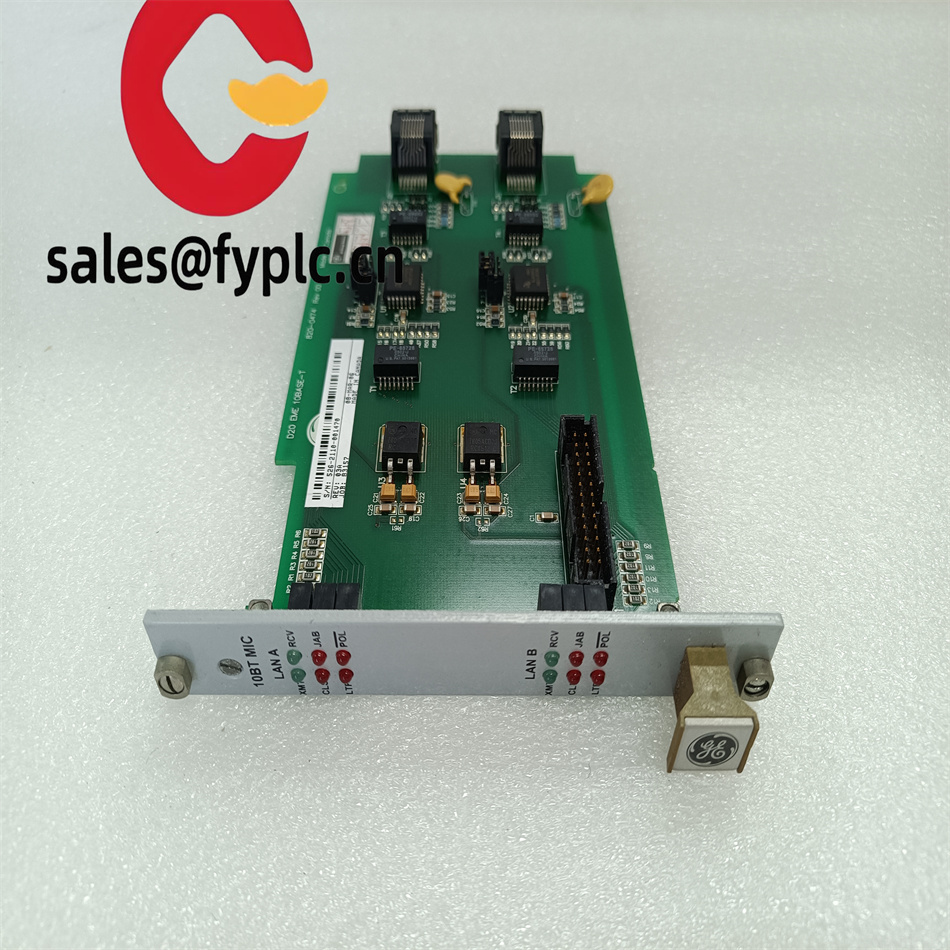

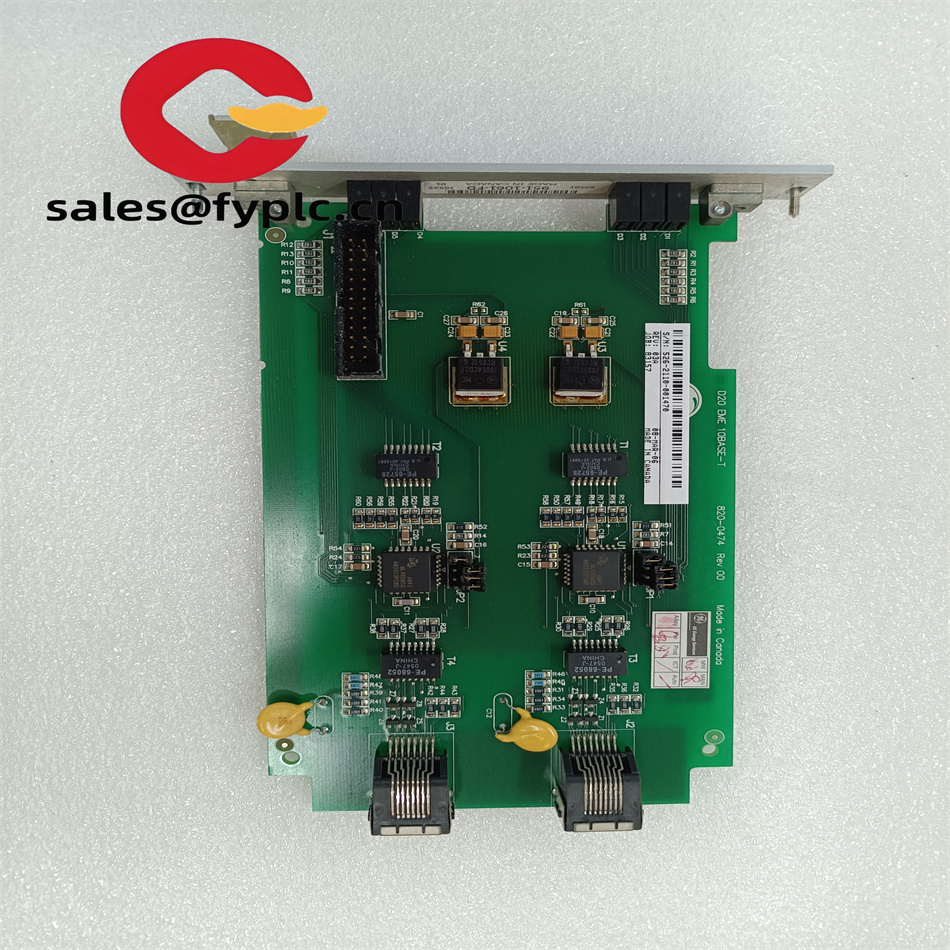

GE D20 EME 10BASE-T Substation Digital Control Module

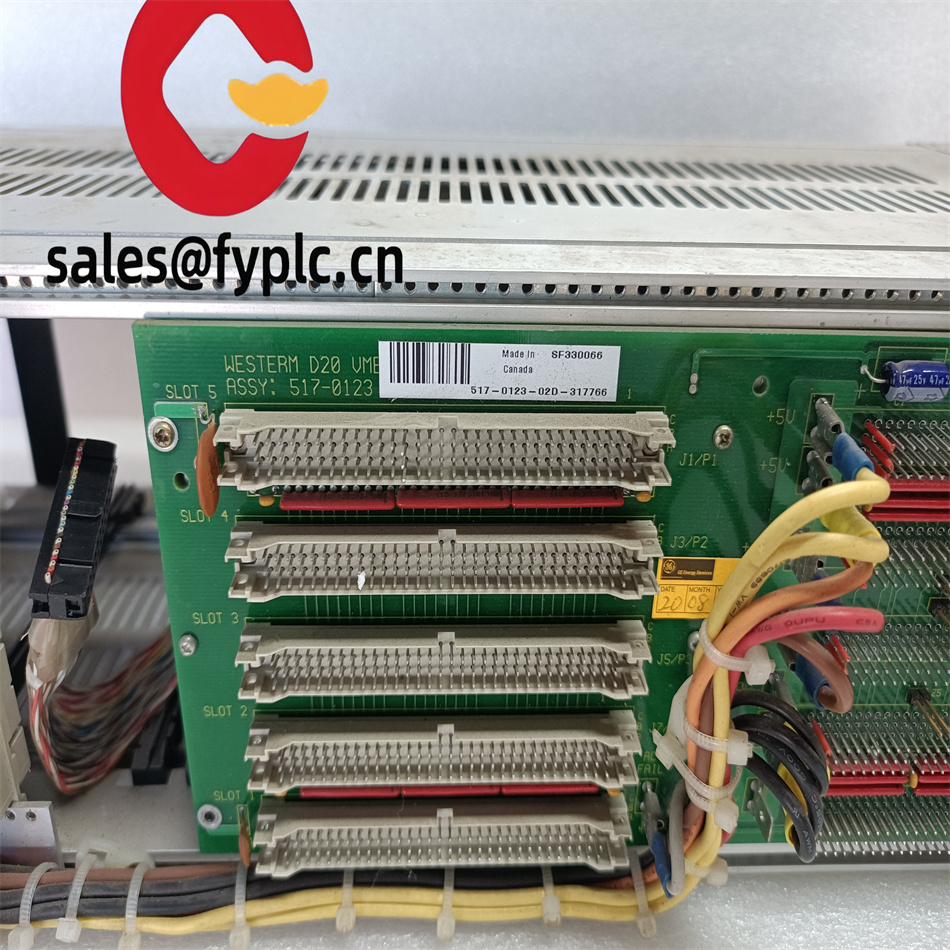

In the dynamic landscape of industrial automation, the GE D20 EME 10BASE-T stands as a reliable and high-performance solution designed to meet the evolving needs of modern control systems. This advanced module is engineered to act as a crucial communication handler, facilitating seamless data transfer and signal processing within industrial setups. Whether it’s integrated into complex Distributed Control Systems (DCS) or Supervisory Control and Data Acquisition (SCADA) environments, the GE D20 EME 10BASE-T ensures smooth operation and enhanced productivity across various industries, from manufacturing plants to power generation facilities.

At its core, the GE D20 EME 10BASE-T is built to provide stable and efficient 10BASE-T Ethernet communication. It enables industrial systems to connect, communicate, and coordinate operations with precision. By integrating this module into your automation infrastructure, you’re equipping your system with the ability to handle real-time data, respond promptly to changes, and optimize overall performance. Its role in the broader industrial control ecosystem cannot be understated, as it serves as a bridge between different components, ensuring that information flows freely and operations run like a well-oiled machine.

The GE D20 EME 10BASE-T shines brightly when it comes to its functional strengths and design advantages. Engineered with speed in mind, this unit can process and transmit data at rates that keep pace with the fast – moving demands of industrial operations. Its resilience is evident in its ability to withstand harsh industrial environments, from extreme temperatures to high levels of electrical noise. Interoperability is another key feature, as the GE D20 EME 10BASE-T is designed to work seamlessly with a wide range of existing industrial equipment and software. The build quality is top-notch, ensuring long – lasting performance even under continuous use. Operators benefit from its straightforward integration process, which minimizes downtime during installation and allows for quick adaptation to new operational requirements.

In real-world industrial use cases, the GE D20 EME 10BASE-T proves its worth time and time again. In manufacturing plants, it plays a vital role in connecting production lines, enabling supervisors to monitor and control operations remotely. This leads to improved process reliability, as any issues can be identified and addressed promptly. In power generation facilities, the module ensures stable communication between different power generation units and the central control system, optimizing power output and reducing the risk of outages. Its ability to handle signal communication accurately and efficiently makes it an indispensable part of industrial automation, delivering significant value in terms of productivity and cost – savings.

Several models are closely related to the GE D20 EME 10BASE-T. The GE D20 EME 100BASE-TX offers a higher – speed alternative for applications that demand faster data transfer. The GE D20 EME Profibus is ideal for setups that rely on the Profibus protocol, providing seamless integration into existing Profibus – based systems. The GE D20 EME Modbus TCP is designed specifically for Modbus TCP – based communication, making it a great choice for systems using this widely – adopted protocol. The GE D20 EME CANopen caters to applications that require CANopen communication, enhancing connectivity in relevant industrial environments. The GE D20 EME DeviceNet is a suitable option for systems utilizing the DeviceNet protocol, ensuring reliable communication within DeviceNet – based networks.

When it comes to setting up the GE D20 EME 10BASE-T, proper installation is key to its optimal performance. During physical installation, ensure that the module is mounted in a well-ventilated area to prevent overheating. Pay attention to grounding requirements to safeguard against electrical surges and ensure accurate signal transmission. For long – term operation, regular inspections are recommended. Check for any signs of wear and tear, loose connections, or abnormal temperature changes. Periodically verify that the communication performance remains consistent and that data transfer rates meet the operational requirements. By following these maintenance practices, you can extend the lifespan of the GE D20 EME 10BASE-T and keep your industrial automation system running smoothly.

For more information, please click below to learn more:

Reviews

There are no reviews yet.