Description

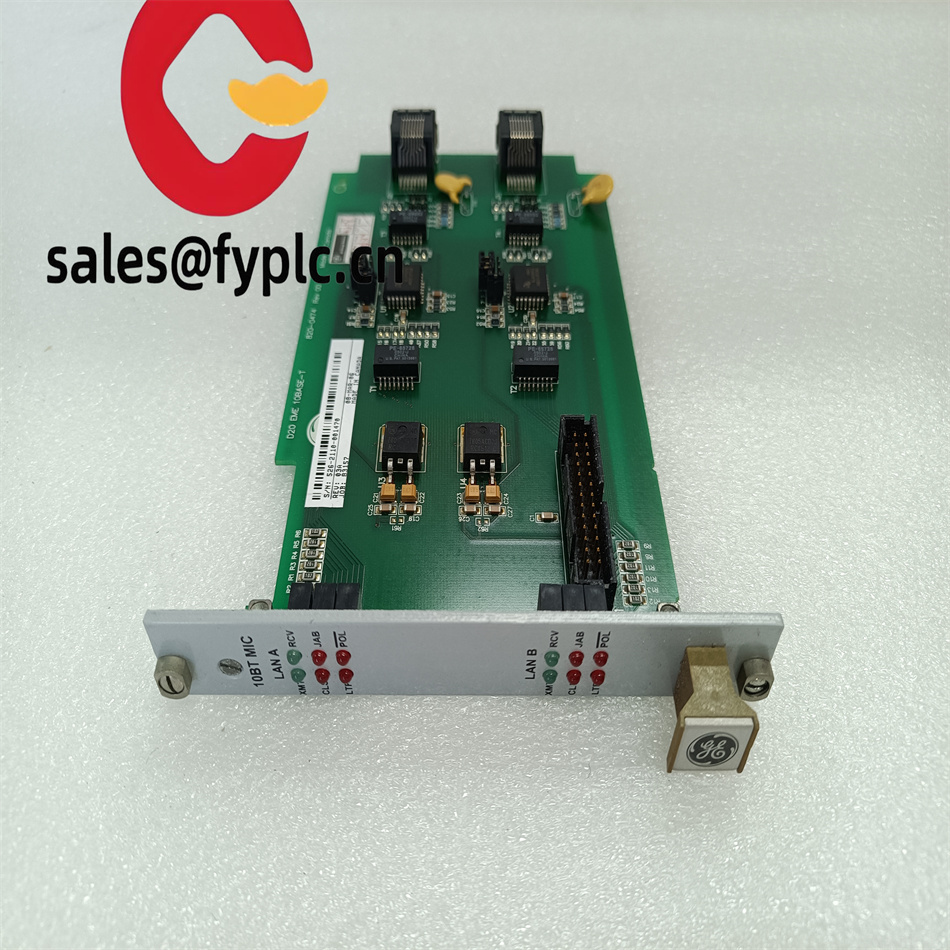

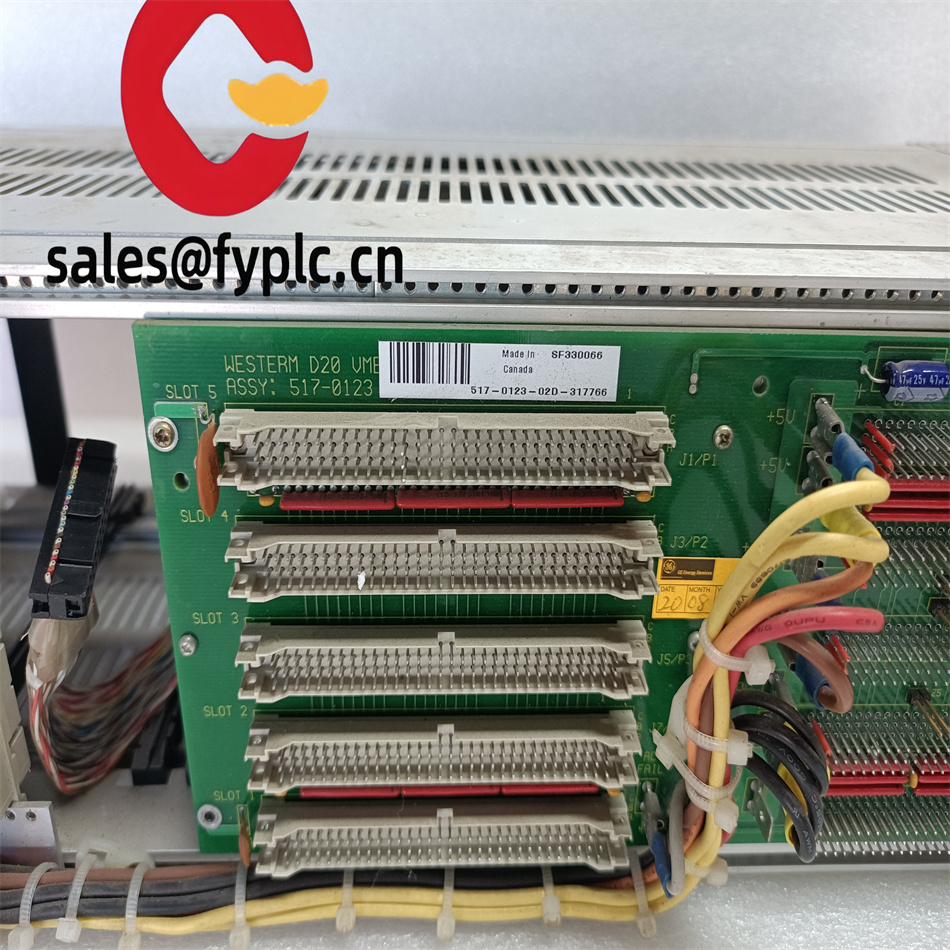

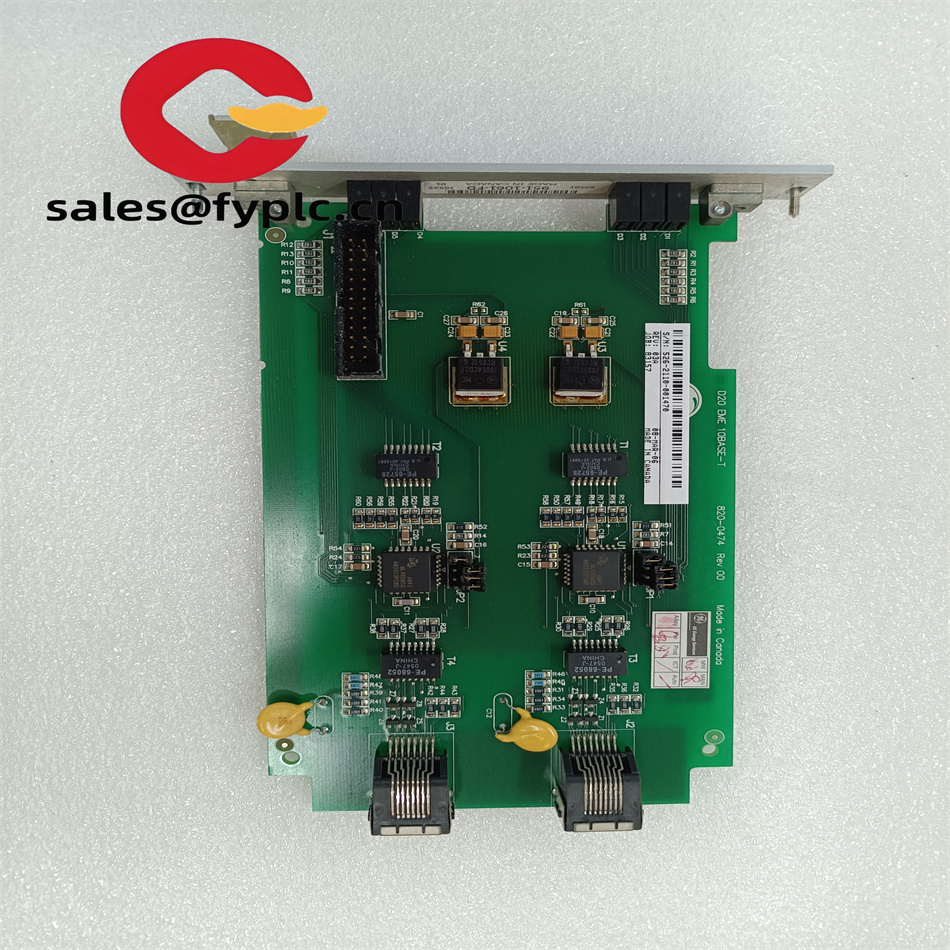

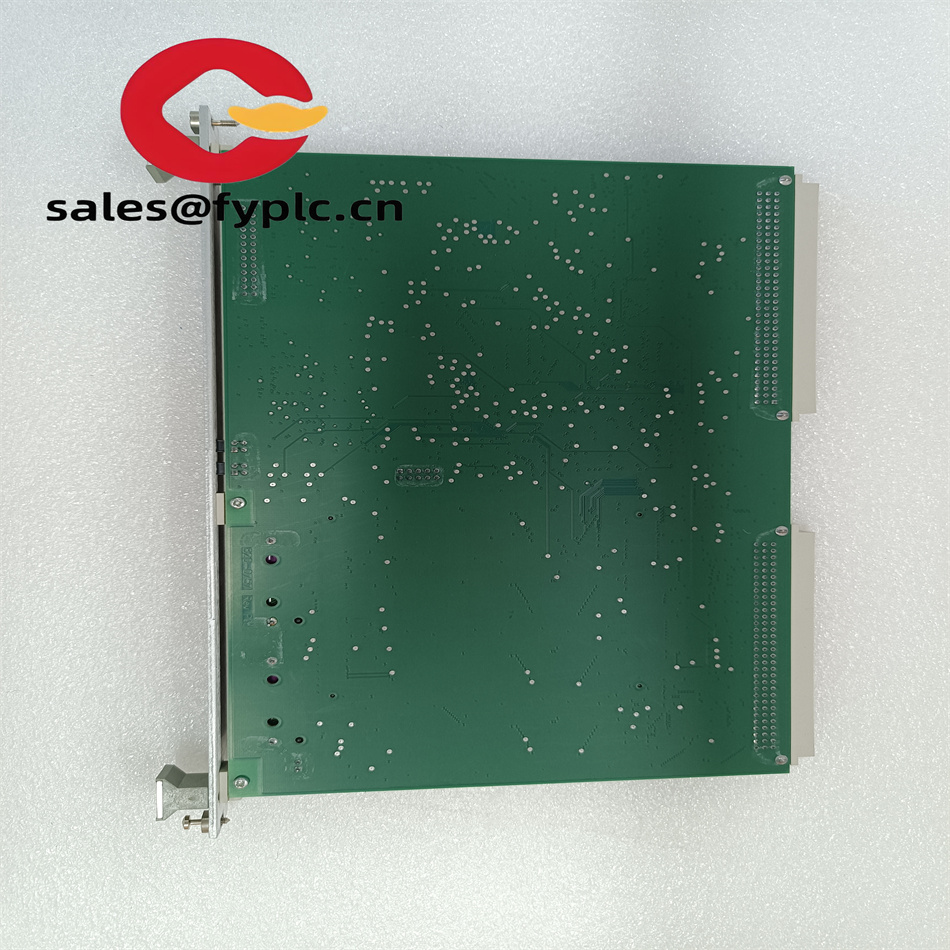

GE D20 EME Digital Input/Output Controller Redundant Module

Exploring the Potential of GE D20 EME in Industrial Contexts

General Electric (GE), a globally recognized conglomerate, has its fingers in numerous industrial pies, from aviation and healthcare to energy and industrial automation. The model designation “GE D20 EME” presents an interesting puzzle. While the exact nature of this product isn’t immediately clear, we can make some educated speculations based on GE’s diverse product portfolio and the possible implications of the “EME” abbreviation, which could potentially stand for “Electromechanical Engineering,” suggesting a product with a strong electromechanical aspect.

Potential Product Categories

Aviation – Advanced Avionics or Engine – Related Electromechanical Component

In the aviation sector, GE is a dominant force, especially in aircraft engines and avionics. The D20 EME could be an advanced avionics module. Modern aircraft rely on a complex network of avionics systems for navigation, communication, and flight control. For example, it might be a high – performance data acquisition and processing unit. In airliners equipped with GE engines, such as those powered by the GEnx series, there is a constant need for real – time data monitoring from various sensors within the engine and across the aircraft. This unit could be responsible for collecting data from sensors measuring parameters like engine vibration, fuel flow, and air pressure. It would then process this data using advanced algorithms to provide crucial information to the flight crew and the engine control system. If the D20 EME is such a component, it would need to be designed to operate flawlessly in the harsh environment of an aircraft, withstanding extreme temperatures, high vibrations, and electromagnetic interference.

Alternatively, it could be an electromechanical component within the engine itself. GE’s engines, like the upcoming adaptive – cycle XA100, are engineering marvels with intricate electromechanical systems. The D20 EME might be part of a fuel injection system or a variable – geometry component that adjusts the engine’s performance based on different flight conditions. For instance, it could be a servo – controlled actuator that precisely adjusts the position of engine vanes to optimize air intake and combustion efficiency. This would require high – precision manufacturing and reliable operation under extreme mechanical and thermal stresses.

|

Label

|

Possible Specification (Based on Hypothetical Product Categories)

|

|

Model Number

|

GE D20 EME

|

|

Brand

|

GE

|

|

If in Aviation – Avionics Module

|

|

|

– Data Processing Rate

|

500 Mbps (to handle high – volume sensor data in real – time)

|

|

– Operating Temperature Range

|

-40°C to 85°C (to withstand aircraft environmental conditions)

|

|

– Vibration Resistance

|

Can endure vibrations up to 50g (to cope with aircraft vibrations)

|

|

– Electromagnetic Compatibility

|

Complies with strict aviation – specific EMC standards

|

|

If in Aviation – Engine Component

|

|

|

– Mechanical Load Capacity

|

Can withstand forces up to 10,000 N (for engine – related mechanical stress)

|

|

– Temperature Resistance

|

Up to 1000°C (in high – temperature engine areas)

|

|

– Actuation Precision

|

±0.1 mm (for precise mechanical adjustments)

|

|

If in Healthcare – MRI Coil Positioning Mechanism

|

|

Potential Applications and Benefits

Aviation

If the D20 EME is an avionics module, it could significantly enhance flight safety and efficiency. By providing real – time, accurate data to the flight crew and engine control system, it enables better decision – making during flight. For example, in case of an engine anomaly, the module can quickly analyze sensor data and provide early warnings, allowing the crew to take appropriate action before a major problem occurs. This can prevent in – flight emergencies and reduce maintenance costs by enabling predictive maintenance. If it’s an engine component, such as an electromechanical actuator, it can optimize engine performance, leading to better fuel efficiency. A more fuel – efficient engine not only reduces operating costs for airlines but also decreases carbon emissions, contributing to a more sustainable aviation industry.

Healthcare

In the healthcare field, if the D20 EME is part of an MRI or ultrasound device, it can improve the quality of medical imaging. For MRI, more accurate coil positioning can result in clearer images, enabling doctors to detect diseases and abnormalities at earlier stages. This is crucial for conditions like cancer, where early detection can significantly improve patient outcomes. In ultrasound, better beam steering and focusing can provide more detailed images, especially in areas where traditional imaging has limitations, such as in the detection of small tumors or in pediatric imaging. Overall, it can lead to more accurate diagnoses and more effective treatment plans for patients.

Energy

In power generation, an electromechanical control device like the D20 EME can optimize the operation of power plants. Precise control of turbines and generators can increase energy efficiency, reducing fuel consumption and operating costs. It can also help in maintaining grid stability by quickly responding to changes in load demand. On the grid side, components like an electromechanical switchgear or capacitor bank control device can improve the reliability of power distribution. By regulating voltage levels and managing reactive power, it can reduce power outages and improve the quality of electricity supplied to consumers. This is especially important in modern smart grids, where the integration of renewable energy sources requires more sophisticated power management.

Industrial Automation

For industrial automation, a high – performance PLC like the D20 EME can streamline manufacturing processes. It can coordinate the operation of multiple machines and robots in a manufacturing plant, ensuring seamless production flow. This can increase productivity, reduce production errors, and lower the cost per unit of production. A sensor – actuator system can enhance the precision of manufacturing processes. In industries where high – precision assembly is required, such as in the electronics or aerospace industries, the accurate sensing and actuation capabilities of the D20 EME can ensure that products are assembled with the highest quality standards. This can improve product quality, reduce waste, and increase customer satisfaction.

In conclusion, while the exact nature of GE D20 EME remains uncertain, based on GE’s diverse industrial footprint, it likely has significant potential in enhancing performance, safety, and efficiency across various sectors. Further research into GE’s product documentation, discussions with industry experts, or direct communication with GE representatives would be required to fully uncover the true identity and capabilities of this product.

For more information, please click below to learn more:

Reviews

There are no reviews yet.