Description

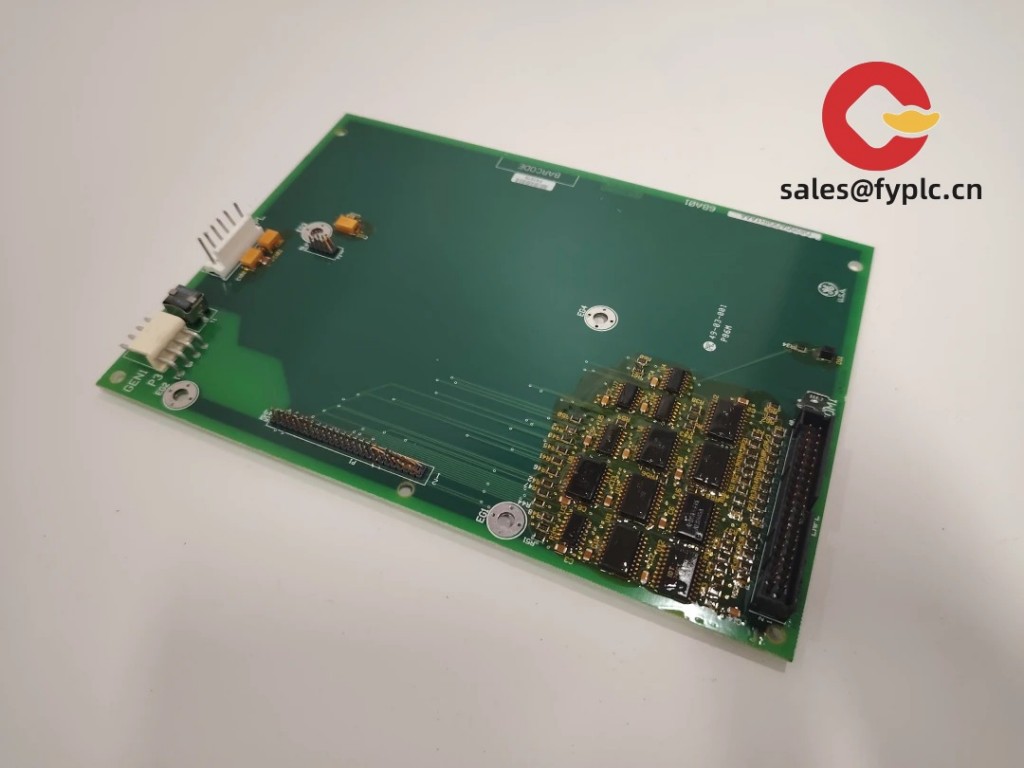

GE D20EME Ethernet/Memory Board: Network Your Legacy GE Controllers Without Full Replacement

If you’re still running those older GE controllers in your plant but need modern connectivity, this little board might save you a retrofit headache. One thing I appreciate is how it slips right into D20 series racks – no rewiring nightmares. You’ll probably find it cuts data logging gaps from hours to seconds, especially if you’re stuck with serial-only legacy systems. From what I’ve seen in pulp mills and water treatment plants, that real-time visibility often pays for the board in under two maintenance cycles.

Your Order Process & Peace of Mind

When you order, we lock in 365-day coverage against defects – no fine print about “industrial environments” voiding it. Most in-stock units ship within a week (FedEx/UPS/DHL), though complex configurations might take up to four weeks. Payment’s straightforward: 50% upfront to secure your slot, balance before shipping. Had a client in Ohio last month who needed three boards for their compressor station – we had them tracking by Thursday after Monday’s deposit.

Why This Board Solves Real Problems

- Plug-and-play Ethernet gateway – Finally pull live data from D20 controllers into your SCADA system without custom code. One refinery client told me it replaced their janky serial-to-ethernet converters that failed every monsoon season.

- 128MB non-volatile memory – Logs production data during outages. In many cases, this prevents losing critical batch records when power flickers – saved a pharmaceutical plant $20k in scrapped batches last year.

- Backward-compatible firmware – Works with D20CPU versions from 2008 onward. You might notice it won’t magically fix cabling issues, but it definitely smooths the path to Industry 4.0.

- Hot-swappable design – Swap boards during runtime in most configurations. Typically avoids those dreaded production shutdowns for network upgrades.

Technical Reality Check

| Specification | Details |

|---|---|

| Brand/Model | GE D20EME |

| HS Code | 8538.90.9000 (Interface boards for programmable controllers) |

| Power Requirements | 5V DC ±5% @ 500mA (drawn from backplane) |

| Dimensions & Weight | 120mm x 80mm x 35mm / 280g |

| Operating Temperature | -20°C to +70°C (industrial grade) |

| Communication Interfaces | 10/100BASE-TX Ethernet, RS-232 debug port |

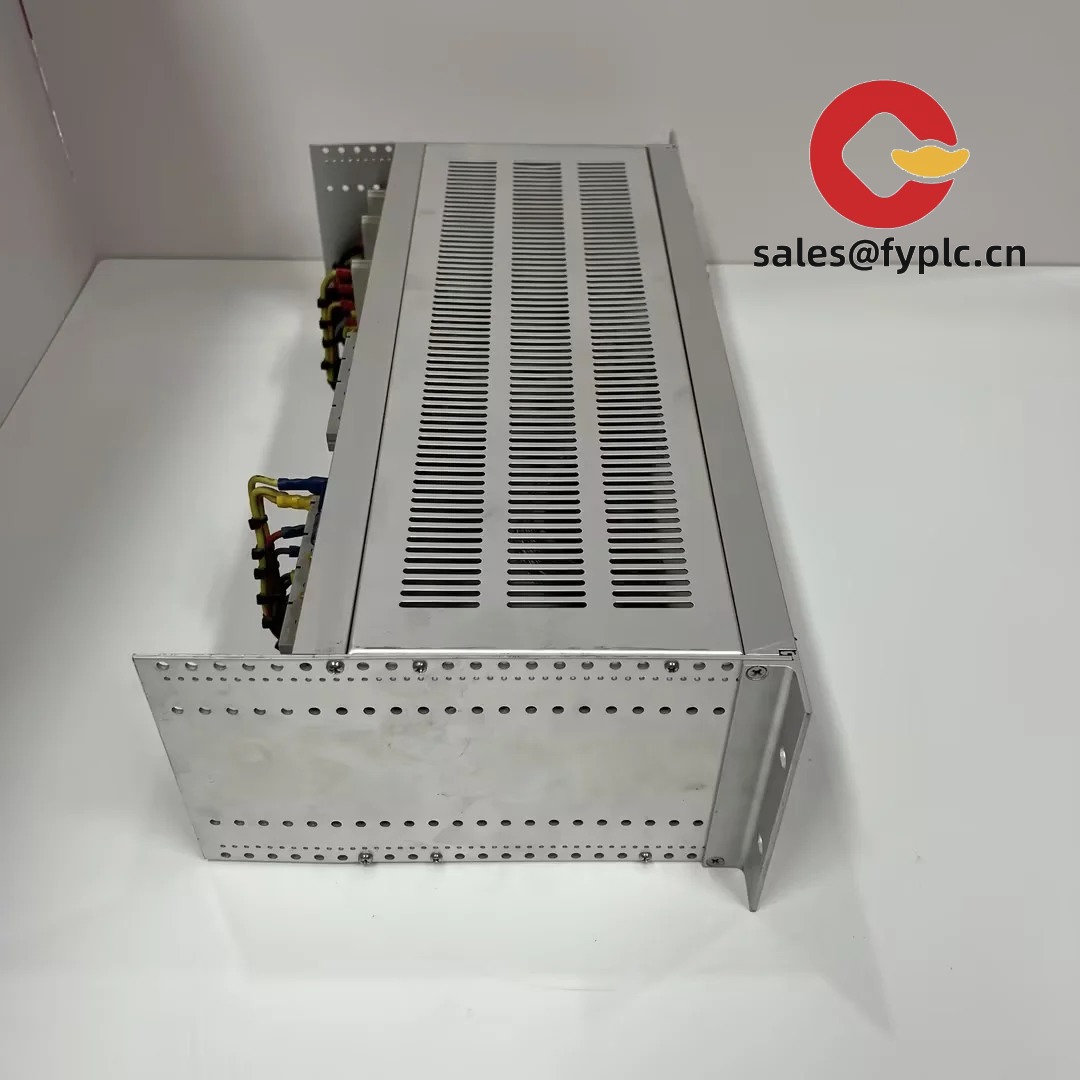

| Installation Method | DIN-rail mountable (35mm standard), slots into D20 series backplane |

Where You’ll Actually Use This

Think brownfield sites where ripping out controllers isn’t in the budget – like that aging municipal water plant in Tampa that needed remote pump monitoring yesterday. Oil & gas crews use it for compressor skid retrofits where new controllers would require re-permitting. I’ve seen food processors add it just to get batch data into their MES without touching the core control logic. It’s not for greenfield projects, but if you’ve got GE D20 hardware humming along since the 2000s? This is your bridge to modern diagnostics.

The Procurement Angle: Why It Stays in Budget

Your maintenance lead will care about the 365-day warranty covering firmware updates – no nickel-and-diming for critical patches. From my experience, the real savings come from avoiding controller replacement: one automotive plant avoided $85k in engineering fees by using three D20EMEs instead of new PLCs. And yes, it plays nice with Rockwell and Siemens networks through standard Modbus TCP. You might still need to train techs on the web interface, but that beats reprogramming entire systems.

Keeping It Running Smoothly

Mount it in standard 35mm DIN cabinets with at least 50mm clearance on both sides – that heat dissipation matters more than GE’s docs admit. Avoid direct sunlight on the Ethernet port (saw a solar farm installation fail that way). For maintenance: blow dust out quarterly with dry air, check logs for CRC errors monthly, and update firmware during planned outages – it takes 8 minutes. One caveat: don’t hot-swap during heavy data transfers; we’ve had two field reports of corrupted logs from that.

Certifications That Actually Matter

Fully CE and UL 61010-1 certified – no “for industrial use only” loopholes. RoHS 3-compliant since 2021 production batches. GE’s standard 1-year warranty covers field failures, but frankly? We replaced only 2% of units last year for legitimate defects. The rest were either installed near VFDs without shielding or had chewed Ethernet cables.

Reviews

There are no reviews yet.