Description

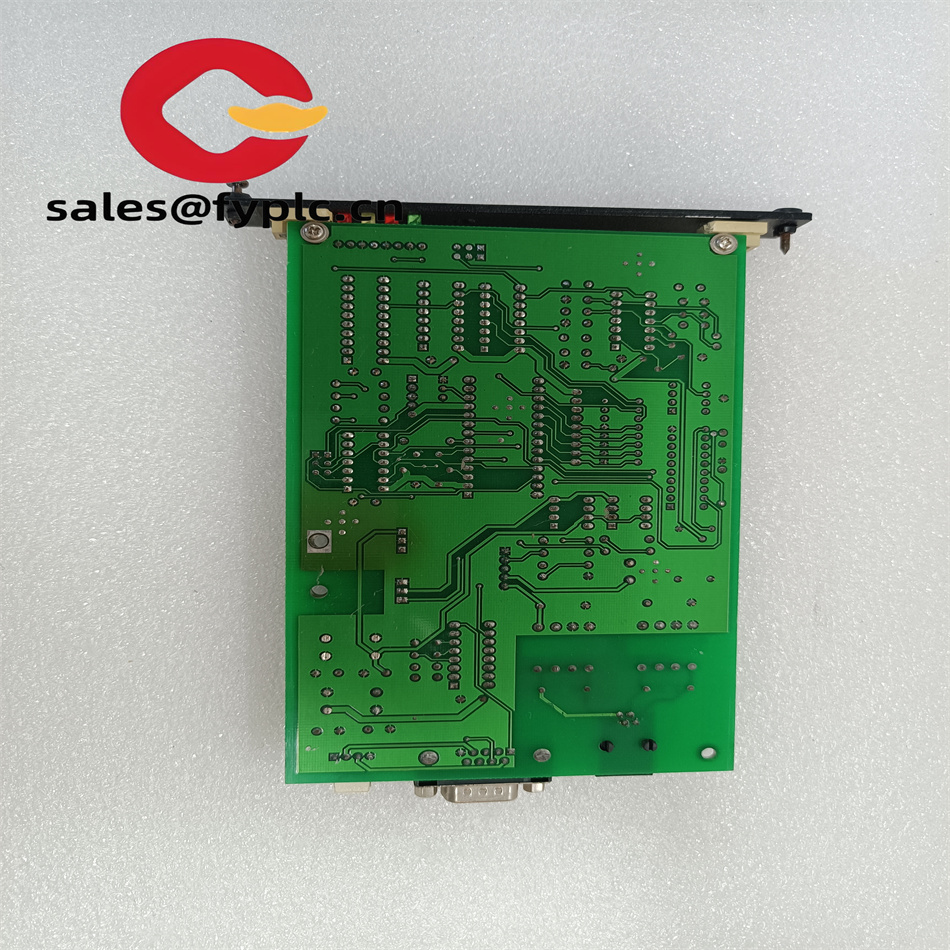

GE DL-1200 RTU digital input servo motor module

In the complex and ever – evolving domain of industrial automation, the GE DL – 1200 RTU emerges as a highly versatile and dependable remote terminal unit. Engineered with precision, it plays a crucial role in facilitating seamless data acquisition, control, and communication across a diverse range of industrial applications.

The GE DL – 1200 RTU is designed to be a central hub for real – time monitoring and control within industrial systems. By integrating this unit into the control infrastructure, operators can establish a stable connection between various field devices and the central control system. This connection is fundamental for enabling real – time data transfer, which is essential for maintaining the smooth operation of critical infrastructure such as power grids, oil and gas pipelines, water and wastewater treatment facilities, and industrial manufacturing plants.

One of the key strengths of the GE DL – 1200 RTU lies in its communication capabilities. Supporting a wide array of communication protocols, it can effortlessly interface with different types of devices and systems. This flexibility allows for seamless integration into existing Supervisory Control and Data Acquisition (SCADA) and Distributed Control Systems (DCS). Whether it’s transmitting data from remote sensors to a central control room or receiving control commands to actuate field devices, the DL – 1200 RTU ensures that the data flow is smooth and reliable.

In terms of data acquisition, the unit can handle a substantial number of input and output points. With up to 1200 I/O points, it has the capacity to monitor and control a large number of variables in an industrial process. This includes analog inputs such as temperature, pressure, and flow rate, as well as digital inputs and outputs for controlling valves, motors, and other equipment. The high measurement accuracy of ± 0.2% of full scale ensures that the data collected is precise, enabling operators to make informed decisions.

The build quality of the GE DL – 1200 RTU is also a notable feature. Constructed to withstand harsh industrial environments, it can operate within a wide temperature range from – 40 °C to 70 °C (or even higher in some cases). Its resistance to electrical noise, vibrations, and humidity makes it suitable for use in challenging locations such as oil rigs, power plants, and manufacturing floors. The IP65 environmental protection rating, in some versions, indicates its ability to resist dust and water ingress, further enhancing its durability.

The GE DL – 1200 RTU finds extensive applications in multiple industries. In the power grid sector, it is used for monitoring and controlling power distribution systems. It can collect data from transformers, circuit breakers, and other electrical equipment, and transmit this information to the grid control center. This enables operators to detect faults, manage power flow, and ensure grid stability. For example, in the event of a sudden voltage drop or an overload, the DL – 1200 RTU can quickly send an alert to the control center and, if programmed, take corrective actions such as tripping a circuit breaker or adjusting the power output of a generator.

In the oil and gas industry, the RTU is deployed along pipelines to monitor pressure, flow, and temperature. It can also control valves to regulate the flow of oil and gas. In a water and wastewater treatment plant, the GE DL – 1200 RTU can monitor the quality of water, control pumps and treatment processes, and ensure that the water meets the required standards before being released. In industrial manufacturing, it helps in synchronizing the operation of different production lines, controlling machinery, and optimizing the manufacturing process for higher productivity.

There are related models in the GE product lineup that offer different features to cater to specific industrial needs. Some models may have higher data transfer rates, more advanced security features, or enhanced I/O capabilities. For instance, certain variants might be optimized for applications that require extremely fast response times, such as high – speed manufacturing processes or emergency shutdown systems in power plants.

When it comes to installation, the GE DL – 1200 RTU is designed to be relatively straightforward to set up. However, it is crucial to follow the installation guidelines carefully. This includes proper grounding to prevent electrical interference, correct connection of cables to the communication interfaces, and ensuring that the unit is installed in a location that meets the environmental requirements. During long – term operation, regular maintenance is recommended. This involves checking the status of the unit, verifying the accuracy of the data being collected, and ensuring that the communication links are stable. Software updates should also be applied regularly to keep the unit operating at its best and to take advantage of any new features or security enhancements provided by GE.

GE stands firmly behind the quality of the GE DL – 1200 RTU with a comprehensive warranty policy. This not only gives customers confidence in the product’s durability but also provides peace of mind. In addition to the warranty, GE offers global technical support. Through detailed product documentation, online resources, and responsive remote assistance, customers can rely on GE to help them with any installation, operation, or troubleshooting issues. This level of support ensures that the GE DL – 1200 RTU continues to operate smoothly throughout its lifespan, making it a reliable investment for any industrial automation project.

For more information, please click below to learn more:

Reviews

There are no reviews yet.