Description

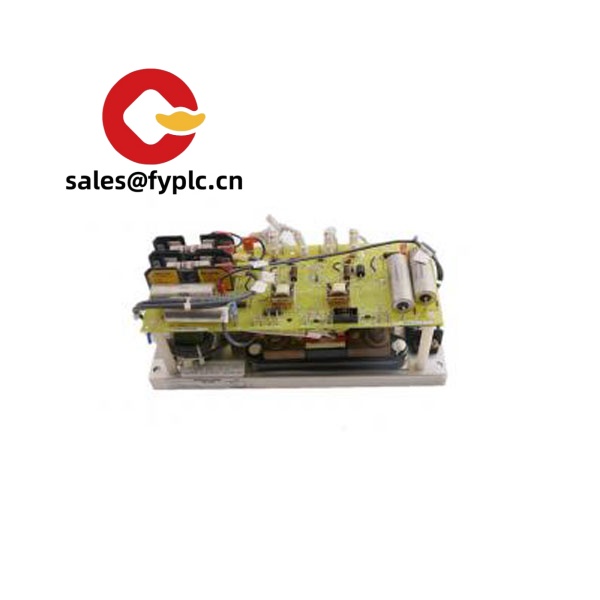

GE DS200AAHAG2A – Analog I/O Conditioning Board for GE Mark V / EX2000 and DC/AC Drive Systems

The GE DS200AAHAG2A is an analog signal conditioning and I/O interface board designed for GE drive and excitation platforms (commonly seen in DC2000/AC2000 drives and EX2000/LS2100 excitation systems). From my experience, this board typically handles the delicate work—scaling, filtering, and buffering analog inputs/outputs—so your controller can process stable, noise‑reduced signals. You might notice that it’s often paired with terminal boards via ribbon cables and edge connectors, which makes field wiring clean and serviceable.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment, full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- Analog signal conditioning – Scales, filters, and buffers voltage/current signals so the main controller receives stable, low‑noise data.

- Multiple channel support – Typically provides several analog input and output paths for process control, feedback, and reference signals.

- Backplane powered – Draws power from the host system rails, keeping cabinet wiring simple and consistent.

- On‑board test points and adjustments – In many cases includes jumpers and trim points to fine‑tune ranges or filtering during commissioning.

- Ruggedized for industrial cabinets – Designed for the electrical environment of GE drives and exciters; installs on standoffs with ribbon cable interconnects.

- Compatible with GE DS200 ecosystem – Works alongside control, power supply, and terminal boards commonly used in Mark V/EX2000 architecture.

Technical Specifications

| Brand / Model | GE DS200AAHAG2A |

| HS Code | 8538.90 (Parts for boards/panels/consoles for electric control of 8537) |

| Power Requirements | Supplied by system backplane; typically logic +5 VDC and analog ±15 VDC rails |

| Dimensions & Weight | Standard DS200 single‑board form factor; lightweight for panel/rack mounting |

| Operating Temperature | Typically 0–60°C inside a ventilated industrial cabinet |

| Signal Input/Output Types | Analog voltage/current I/O, conditioned via filters and buffers; differential/single‑ended as configured |

| Communication Interfaces | Backplane edge connectors and ribbon headers; no Ethernet/serial ports on board |

| Installation Method | Plug‑in PCB with standoff mounting; connects to terminal/control boards via ribbon cables |

| Revision / Group | G2 functional grouping; “A” hardware revision |

Application Fields

The DS200AAHAG2A shows up in GE drive and exciter cabinets where reliable analog measurement and reference control matter. Typical deployments include:

- DC2000 / AC2000 variable speed drives used in metals, mining, cement, and paper lines

- EX2000 / LS2100 static excitation systems in power generation (steam, gas, and hydro)

- Process analog I/O interfacing for Mark V–era platforms where conditioning and isolation are needed

Advantages & Value

- Reliability – Proven GE DS200 hardware platform; stable analog performance helps reduce drift and nuisance trips.

- Compatibility – Designed to integrate with common GE control and terminal boards, easing replacement in mixed‑age cabinets.

- Cost Savings – Drop‑in board replacement typically avoids major rewiring or software changes, shortening downtime.

- Technical Support – Clear test points and jumper logic make commissioning and troubleshooting predictable for field technicians.

“Swapping in the DS200AAHAG2A stabilized our generator feedback loop—noise on the analog reference fell noticeably. Commissioning was straightforward with existing ribbon harnesses.”

Installation & Maintenance

- Environment – Install in a clean, ventilated cabinet (IEC/NEMA industrial enclosure). Maintain airflow around boards; avoid condensation.

- Wiring – Use the original ribbon cable orientation; verify keyed headers. Keep analog runs separated from high‑power cabling to limit EMI.

- Safety – De‑energize and lock out before servicing. Observe ESD precautions; handle by edges only.

- Commissioning – Check jumper settings against the system print. Validate analog scaling with a calibrated DMM and simulated input signals.

- Routine care – Quarterly visual inspection for loose fasteners or connector oxidation; light, dry air cleaning only. Re‑verify analog ranges after major maintenance.

- Firmware – This board typically has no field‑updatable firmware; adjustments are hardware‑based (jumpers/trim as applicable).

Quality & Certifications

- CE compliant when installed in the OEM GE system configuration

- UL considerations at the cabinet/system level (GE drive/exciter assemblies)

- Manufactured under ISO 9001 quality systems (typical for GE factories)

- RoHS status depends on production lot and revision; verify per DS200AAHAG2A label if required

- Backed by a 365‑day warranty

One thing I appreciate is how predictable the DS200AAHAG2A behaves once it’s in a stable cabinet environment—noise performance seems to be consistent across replacements, which is what maintenance teams want during a tight outage window.

Reviews

There are no reviews yet.