Description

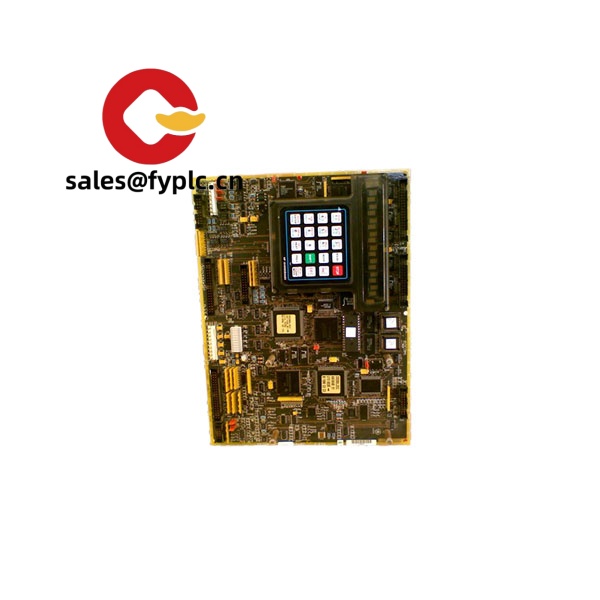

GE DS200CPCAG1 – Control/Communication Board for DS200-based Drives and Mark V Systems

The GE DS200CPCAG1 is part of the DS200 board family used across GE DC2000/AC2000/EX2000 drive platforms and, in many cases, within Mark V turbine control cabinets. From my experience, this board typically functions as a control/communications core in the rack, coordinating signals on the backplane, managing interlocks, and linking peripheral I/O to the system processor. You might notice that it’s designed as a direct, plug-in replacement to simplify downtime—pull the old, seat the new, move the configurable items, and you’re back in service.

Our Order Placement Process and Guarantees

- Warranty: 365 days from delivery.

- Lead time: 1 week if in stock; no more than one month at the latest.

- Payment: 50% advance payment; full balance prior to delivery.

- Express options: FedEx, UPS, DHL (we’ll pick the most reliable route for your region).

Key Features

- DS200 backplane integration – Designed to plug directly into GE drive and Mark V racks, no external field power typically required.

- System communications hub – Manages data exchange across the rack and attached I/O cards; reduces wiring complexity.

- On-board diagnostics – Status LEDs and test points simplify commissioning and fault tracing during outages.

- Field-configurable – Jumpers/DIP selections (where fitted) allow tailoring to cabinet configuration without rework.

- Service-friendly design – Supports quick swap-out; in many cases you can transfer socketed firmware devices from the old board to maintain site configuration.

- Form/fit compatible – G1 variant follows the base functional group for common DS200 installations.

Technical Specifications

| Brand / Model | GE DS200CPCAG1 |

| HS Code | 8538.90 (Parts suitable for use with industrial control apparatus) |

| Power Requirements | Powered from DS200/Mark V backplane; no separate field supply in typical installations |

| Operating Temperature | 0 to 60 °C typical (cabinet-installed, forced-ventilated environment) |

| Signal I/O Types | Backplane digital data, ribbon-cable headers to adjacent I/O, on-board test points and status LEDs (varies by revision) |

| Communication Interfaces | Rack/backplane data bus; service/diagnostic headers used for commissioning or troubleshooting |

| Installation Method | Plug-in PCB for DS200/Mark V rack; fixed with board guides and multi-pin connectors; ESD-safe handling required |

Application Fields

This board is commonly used as a control/communications element in:

- GE DC2000/AC2000 adjustable-speed drives for fans, pumps, and compressors

- GE EX2000 excitation systems and related auxiliaries

- Mark V turbine control cabinets (gas/steam) where DS200-family boards provide rack-level coordination

- Process industries such as power generation, oil & gas, metals, paper, mining—anywhere DS200 platforms are installed

Advantages & Value

- Drop-in compatibility – Minimizes rewiring and engineering time during a swap.

- Reliability – Proven DS200 architecture; spares strategy is straightforward for plants running mixed GE drive/Mark V fleets.

- Lifecycle cost control – Replacing a single card is often far cheaper than upgrading a complete drive or turbine control cabinet.

- Technical support – Guidance on jumper positions, firmware transfer, and commissioning helps keep downtime short.

- Logistics assurance – Clear lead times and express carriers limit schedule risk on critical outages.

Installation & Maintenance

- Cabinet environment: Install in a clean, ventilated enclosure (NEMA 12 / IP54 or better is typical). Maintain airflow to keep board temperatures within range.

- ESD precautions: Use a grounded wrist strap; handle by edges only. Verify power is isolated and residual energy discharged before removal.

- Board swap tips: Photograph jumper/DIP settings first; transfer any socketed firmware devices from the original board if required to preserve site configuration.

- Wiring and connectors: Seat all backplane and ribbon connectors firmly; avoid pin damage. From my experience, reseating once after thermal soak can prevent intermittent faults.

- Routine care: Quarterly dust removal with clean, dry air; check standoffs and guides; review event logs/LED histories after trips.

- Firmware/configuration: Keep a copy of the cabinet’s current revision set. If the site standard changes, label the board clearly before storage.

Quality & Certifications

- CE/UL: GE DS200 boards are typically used within CE-marked and UL-recognized systems; component recognition applies when installed per the OEM manual.

- ISO 9001: Manufactured under ISO 9001 quality systems at the OEM level.

- RoHS: Compliance status can vary by production vintage; many legacy DS200 boards predate RoHS—confirm per lot if your site requires it.

- Warranty: 365-day warranty against functional defects under normal use.

One thing I appreciate is how the DS200CPCAG1 tends to pair well with common DS200 control stacks—if you’re also refreshing related modules (for example, DS200SDCC or I/O terminal boards), we can align revisions so you don’t chase nuisance compatibility issues later.

If you can share the cabinet type and your current board revision sticker, I’ll match the exact variant and confirm jumper positions before we ship. That usually saves a service call.

Reviews

There are no reviews yet.