Description

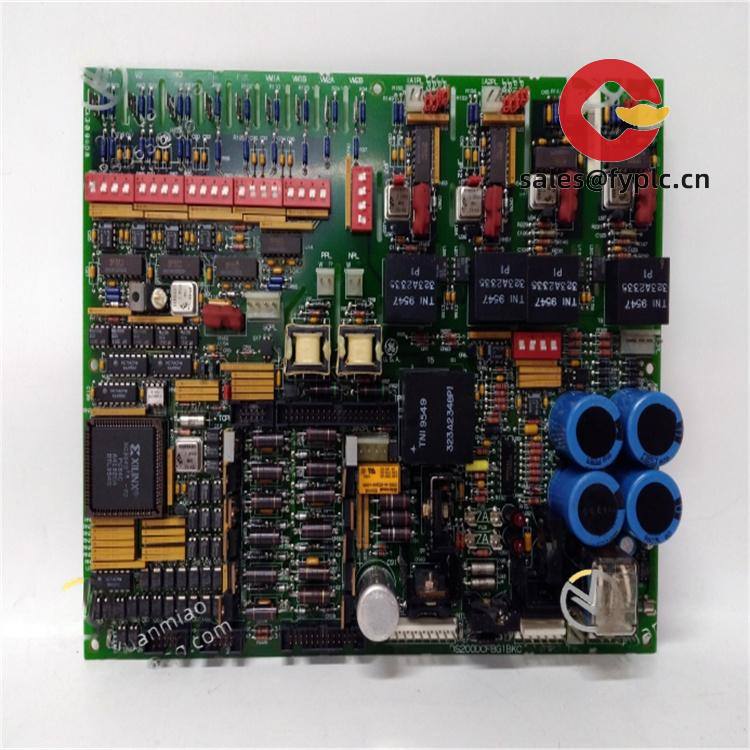

GE DS200CTBAG1ADD – Contactor/Terminal Board for Reliable Discrete I/O Termination

The GE DS200CTBAG1ADD is a CTBA-series terminal board typically used to terminate and distribute discrete contact signals in GE industrial control systems (often seen across Mark V and EX2000/DC2000 platforms). From my experience, it’s the board you pick when you need clean, labeled screw-terminals for field wiring and a straightforward way to hand off those signals to the controller via internal connectors—without overcomplicating the panel.

One thing I appreciate is how the CTBA layout keeps maintenance simple: barrier-strip terminals are easy to trace, and the revision level “ADD” indicates a mature hardware spin that has been widely adopted in service work. You might notice that this board is commonly stocked as a drop-in spare, which makes sense—swaps are fast and, in many cases, wiring lands in minutes.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

- Pre‑ship checks: Visual inspection, basic continuity of terminals, and packaged with ESD-safe materials

Key Features

- Purpose-built terminal board: Provides organized screw-terminal points for discrete contact I/O, reducing wiring clutter and field errors.

- Internal ribbon/backplane interface: Hands off signals to the controller core via internal connectors—no fieldbus setup required.

- Robust barrier strips: Labeled terminals for dry contacts and relay circuits; makes loop checks and service easier.

- Revision “ADD” hardware: A later hardware revision that, in many cases, is chosen for like‑for‑like replacement in legacy panels.

- Form/fit for GE panels: Fits standard GE rack/panel layouts commonly used in Mark V or EX2000/DC2000 cabinets.

- Low maintenance: Passive design with no firmware—usually just inspect terminals and cleanliness during shutdowns.

Technical Specifications

| Brand / Model | GE DS200CTBAG1ADD (CTBA Terminal Board) |

| HS Code | 8538.90 – Parts for switchgear/control equipment |

| Power Requirements | Passive board; no separate power supply (interfaces to control rack) |

| Signal I/O Types | Discrete contact inputs/outputs via screw-terminal barrier strips (dry contact/relay circuits) |

| Communication Interfaces | No fieldbus; internal ribbon/backplane connectors to GE controller hardware |

| Operating Temperature | Typically 0–60°C (panel/cabinet dependent) |

| Dimensions & Weight | Board-level module, standard GE CTBA form factor (fits GE rack/panel mounting) |

| Installation Method | Rack/panel mounted; field wiring to screw terminals; ESD-safe handling recommended |

Application Fields

This board is commonly used in:

- GE Mark V turbine control cabinets (gas/steam) for discrete contact I/O termination

- GE EX2000/DC2000 drive and excitation systems where contactor and relay circuits need organized termination

- Balance-of-plant panels requiring clean hand‑off of field dry contacts to the controller core

One maintenance lead told us, “Swapping a DS200CTBAG1ADD takes less time than re-landing a terminal strip—we keep one on the shelf because it saves a shutdown when a strip gets damaged.”

Advantages & Value

- Form, fit, function: OEM‑compatible layout that typically drops into existing GE panels without mechanical rework.

- Reduced commissioning time: Clear labeling and barrier strips speed up loop checks and troubleshooting.

- Lower risk in legacy systems: Passive design means fewer failure points; no firmware to match.

- Procurement confidence: Tested before shipment, backed by a 365‑day warranty and responsive support.

Installation & Maintenance

- Environment: Mount in a clean, ventilated control cabinet; avoid moisture and conductive dust. Follow standard Mark V/EX2000/DC2000 cabinet practices.

- Wiring: Use ferruled conductors where possible; torque screw terminals to manufacturer guidance; maintain strain relief and segregation from power cables.

- Safety: De‑energize circuits before service; observe ESD precautions; verify terminal IDs against the panel drawings prior to landing wires.

- Routine care: During outages, check terminal tightness, look for discoloration, and gently clean dust with dry air; document any re‑landed conductors.

- Compatibility checks: The suffix “ADD” denotes a later revision; in most cases it’s backward‑compatible within the same group (G1). Review your bill of materials to confirm fit.

Quality & Certifications

- Typically used inside CE/UL certified control cabinets; board-level components are manufactured to GE quality standards.

- Legacy hardware may be RoHS‑exempt depending on build date; documentation can be provided with the shipment when available.

- Each unit is inspected and functionally verified prior to dispatch; 365‑day warranty applies.

Reviews

There are no reviews yet.