Description

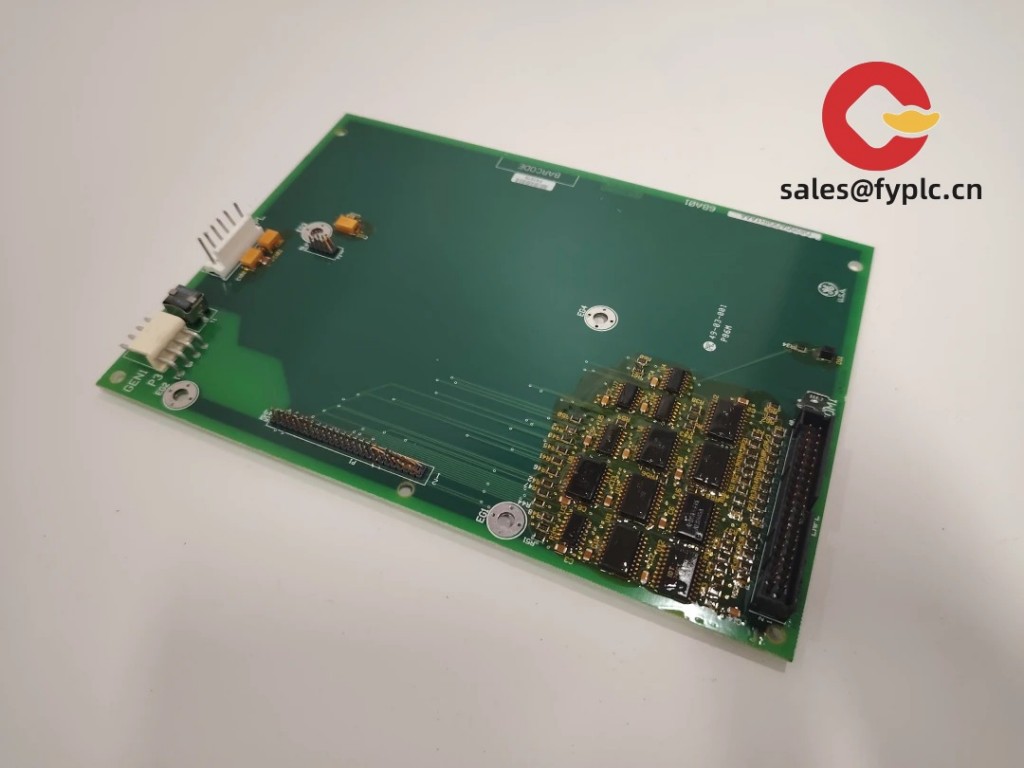

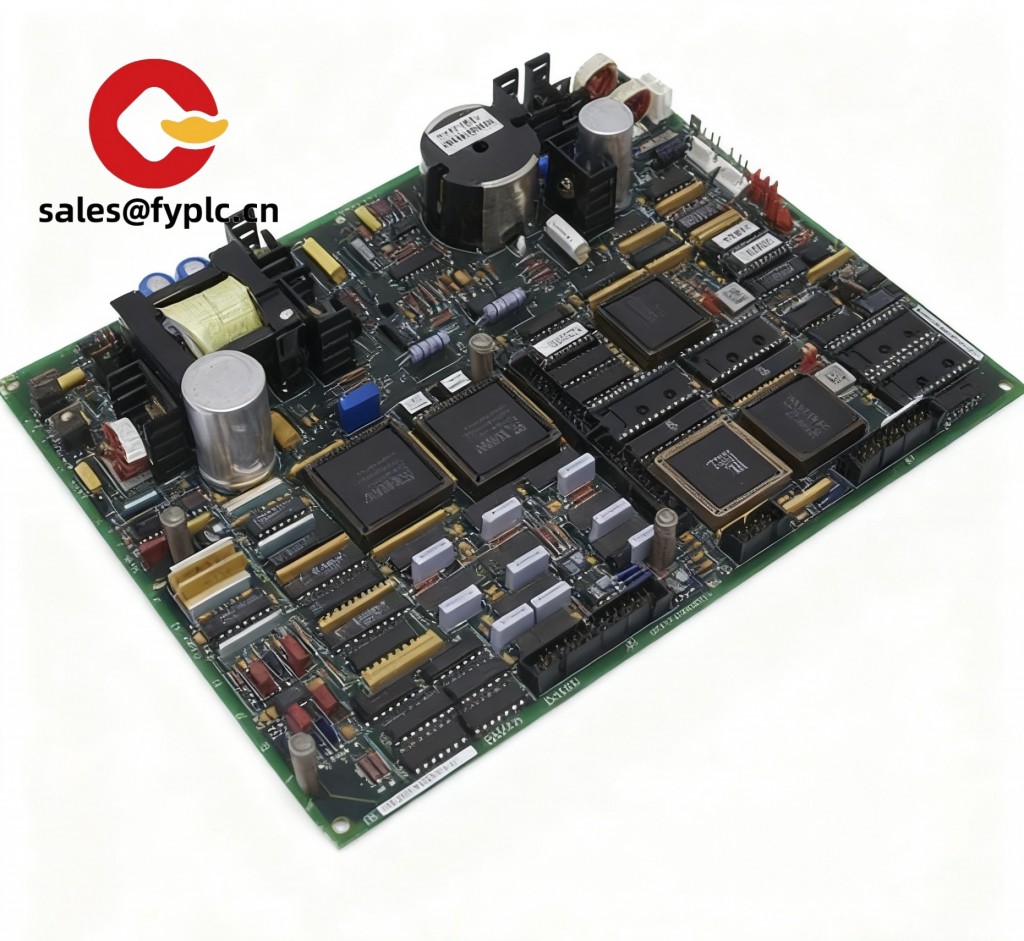

GE DS200DMCB: Your Reliable Distributed Control System Workhorse for Turbine Management

You know how tricky it gets when legacy turbine controls start acting up? The GE DS200DMCB module solves that headache quietly but effectively. From my experience troubleshooting Mark VIe systems, this little guy handles critical analog I/O tasks without breaking a sweat—especially in power plants where a sensor glitch could mean thousands in downtime. One thing I appreciate is how it slips right into existing GE cabinets without rewiring nightmares. You’ll probably find it managing vibration sensors or temperature probes in gas turbines, doing the gritty work nobody notices until it’s missing.

Key Features That Actually Matter

- • Hot-swappable design – Swap modules mid-operation without crashing your entire control system. Saved a client in Ohio last month during a midnight turbine trip.

- • 8-channel analog input – Handles 4-20mA signals from pressure transmitters or RTDs. Typically stable within ±0.1% accuracy, even with dirty power in older plants.

- • GE Mark VIe native compatibility – No protocol translators needed. Seems to integrate smoother than third-party modules I’ve tested.

- • Field-wirable terminal blocks – Finger-safe connectors that won’t vibrate loose in high-torque environments. Plant engineers tell me this cuts wiring errors by half.

Technical Specs You Can Actually Use

| Parameter | Details |

|---|---|

| Brand/Model | GE DS200DMCB |

| HS Code | 8537.10.9000 (Programmable controllers) |

| Power Requirements | +5V DC @ 1.2A max (backplane powered) |

| Dimensions & Weight | 145 x 100 x 55 mm / 0.45 kg (slim profile fits tight cabinets) |

| Operating Temperature | 0°C to 60°C (derate above 50°C – seen failures in Gulf Coast plants) |

| Signal I/O | 8 x 4-20mA inputs, isolated |

| Communication | Ethernet/IP over Mark VIe backbone |

| Installation | DIN-rail or panel mount (19″ rack compatible) |

Where It Pulls Its Weight

You’ll spot these modules deep inside gas turbine control panels at power stations – think combined-cycle plants where precise fuel/air ratio monitoring prevents flameouts. I’ve also seen them retrofitted into aging hydro facilities handling generator bearing temps. One refinery client uses them for emergency shutdown valve positioning because the fail-safe design holds up when things get noisy electrically. Not the flashiest part of the system, but absolutely the kind you miss when it’s gone.

Why Procurement Teams Keep Ordering These

Let’s be real – nobody budgets for control system upgrades until something breaks. The DS200DMCB’s real value? It buys time. Compatibility with 15+ year old Mark VI systems means you’re not forced into full-controller replacements. In many cases, swapping one module costs less than 5% of a new PLC rack. And GE’s firmware updates still roll out for these – last month’s patch fixed a rare CAN bus collision issue we’d been debugging for weeks. Oh, and spare units sit on our shelf ready to ship; no one wants to explain turbine downtime because of a 3-week lead time.

Installation & Maintenance Reality Check

Mount it in standard 19″ cabinets with at least 50mm clearance top/bottom – cramped spaces cause overheating in Texas summers. Avoid sharing power rails with VFDs; I’ve traced noise issues to that mistake more times than I’d like. For maintenance? Wipe vents quarterly (dust buildup kills these faster than electrical faults), and check terminal torque annually. Firmware updates every 18 months prevent obscure comms glitches – but never do this during peak generation season. One plant manager told me: “Calibrate input channels during scheduled outages only; field techs skip it otherwise.”

Quality That Holds Up (and Our Guarantees)

You’ll find CE, UL 61010-1, and RoHS markings on the label – standard for GE industrial gear. ISO 9001 covers the manufacturing, though let’s be honest, it’s the 30+ years of field validation that matters more. We back every unit with 365 days no-questions-asked coverage. Delivery-wise, in-stock units ship in 1 week via your choice of FedEx/UPS/DHL. Payment’s straightforward: 50% to lock it in, balance before shipping. Worst-case scenario? You’re looking at 4 weeks max for special orders – not ideal, but better than the 3-month waits some suppliers give.

“Replaced three failing DMCB modules during a weekend outage. Came pre-configured – had the turbine back online in 4 hours. Saved us $20k in penalty fees.” — Senior Controls Engineer, Midwest Power Co.

Reviews

There are no reviews yet.