Description

GE DS200DMCBG1AKG Drive Control/Processor Board – Reliable CPU core for GE DC/AC drive and exciter systems

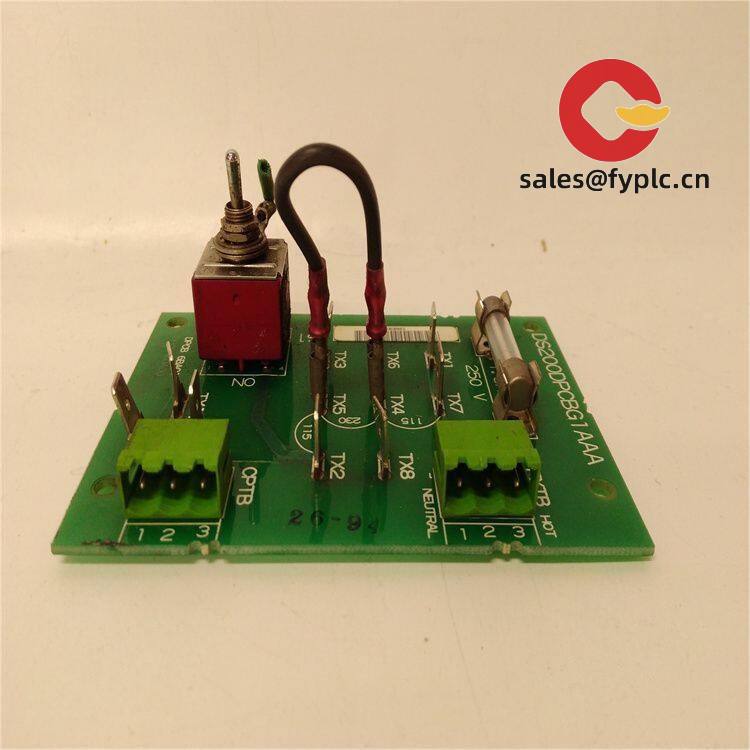

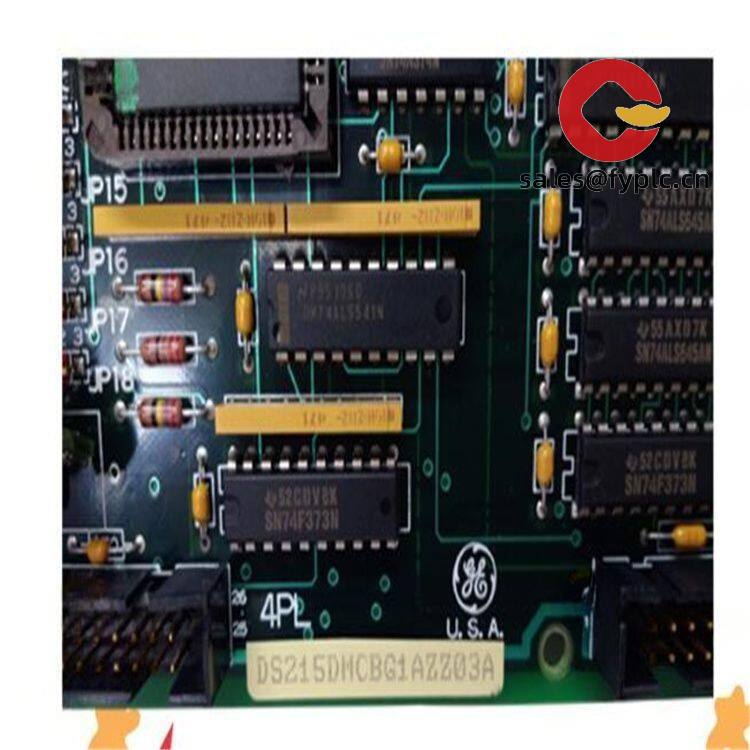

The DS200DMCBG1AKG is a GE DS200-series control/processor board used as the central processing and coordination module in many GE industrial drive and exciter platforms. From my experience, it’s often the board that ties feedback, logic, and drive sequencing together—so when it’s stable, the whole line tends to run smoother. You might notice that it slots into the standard GE DS200 card rack and mates with multiple ribbon/edge connectors for fast replacement during planned downtime.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery: FedEx, UPS, DHL

- Process: Confirm model and revision → We issue PI → Receive advance → Functional test & pack → Ship via your preferred carrier → After-sales follow-up

Key Features

- Processor-centered control – Coordinates key drive logic, speed/torque loops, and interlocks; typically the “brain” of the cabinet section.

- DS200 form factor – Fits GE DS200 racks with standard standoffs and guides, simplifying field swaps.

- Multi-connector backplane interface – Ribbon and edge connectors for fast, positive mating to adjacent boards and I/O harnesses.

- Status and diagnostics – Onboard LEDs and configurable jumpers/DIP (depending on revision) to streamline commissioning and fault isolation.

- Analog and digital signal handling – Designed to process typical ±10 V analog feedback and logic-level signals used across GE drives and exciters.

- Field serviceable – From my experience, swapping like-for-like revisions and matching firmware labels minimizes re-tuning downtime.

Technical Specifications

| Brand / Model | GE / DS200DMCBG1AKG |

| HS Code | 853890 (Parts suitable for use with industrial control equipment) |

| Power Requirements | Supplied by the drive backplane; typically +5 VDC logic and ±15 VDC analog rails |

| Dimensions & Weight | Standard GE DS200 full-size PCB format; fits DS200 card guides and standoffs |

| Operating Temperature | Conforms to host enclosure limits; typically 0–50 °C inside ventilated drive cabinets |

| Signal I/O Types | Proprietary backplane/ribbon connectors; analog ±10 V sensing and logic-level digital signals (typical) |

| Communication Interfaces | GE drive backplane bus via edge and ribbon connectors |

| Installation Method | Plug-in card; mounts in DS200 rack with guide rails and standoffs, secured with captive screws |

Application Fields

This board appears widely in GE DC/AC drive systems and excitation cabinets—commonly seen in DC2000/AC drive lines and many EX-series exciters. Typical deployments include:

- Metals (rolling mills, tension control, coilers/uncoilers)

- Pulp & paper (web handling, winders, calenders)

- Mining & cement (conveyors, crushers, kilns)

- Power generation (generator excitation cabinets and auxiliaries)

- General industrial lines where GE DS200-based drives are installed

One maintenance manager told us a swap of DS200DMCBG1AKG cut their restart time by half compared with reworking older processor cards—mostly because the connectors and form factor line up exactly and field parameters stayed intact.

Advantages & Value

- Reliability – Mature hardware that typically runs for years in high-temperature, high-dust environments when cabinets are maintained.

- Compatibility – Drop-in fit for DS200 racks; no panel rework, keeps existing wiring harnesses.

- Cost savings – Extends the life of installed GE drives/exciters without a full system upgrade.

- Lead time – Stock-based fulfillment in many cases; we target next-week shipment if available.

- Technical support – Guidance on firmware label matching, jumper settings, and post-install health checks.

Installation & Maintenance

- Environment – Install in a clean, ventilated cabinet. Maintain airflow around the card rack; follow drive manufacturer clearance guidelines.

- Wiring & seating – Power down and lockout-tagout. Use ESD protection. Seat the board evenly in guides, tighten captive screws, and verify each ribbon/edge connector is fully engaged.

- Firmware & revision – Match firmware labels/EPROMs and board revision where specified by your drive build sheet. Mixing revisions can work but sometimes requires parameter review.

- Safety checks – Inspect grounding, standoffs, and shielding. After power-up, check status LEDs and alarms before enabling drives.

- Routine care – Quarterly light dust removal with dry air (low pressure), verify connectors for oxidation, and log any intermittent faults. Keep cabinet filters clean to reduce thermal stress.

Quality & Certifications

- Typically deployed within CE/UL-compliant GE drive systems; the board follows OEM manufacturing standards.

- ISO-based quality controls applied in testing and handling on our side.

- RoHS status can vary for legacy DS200 hardware; many units predate RoHS, so we check per lot if this matters for your site.

- Warranty: 365 days, covering functional performance under normal specified use.

Common Companion Components (for planning)

To round out a service kit, teams often keep related DS200 modules and spares on hand. Availability varies, but examples include:

- GE DS200SDCCG1 series – Main drive control card family used alongside processor/control boards.

- GE DS200PCCAGx – Power/feedback interface card variants used for current and voltage interfacing.

- Ribbon harness kits for DS200 racks – Replacement 20/26/34-pin flat cables to address intermittent connection issues.

- EPROM/firmware sets (matched to your drive build) – Helps keep a cold spare aligned with the running system.

If you’d like, share your current drive model, firmware labels on the existing DS200DMCBG1AKG, and any alarm codes you’re seeing. We’ll verify interchangeability and line up the right revision so commissioning stays predictable.

Reviews

There are no reviews yet.