Description

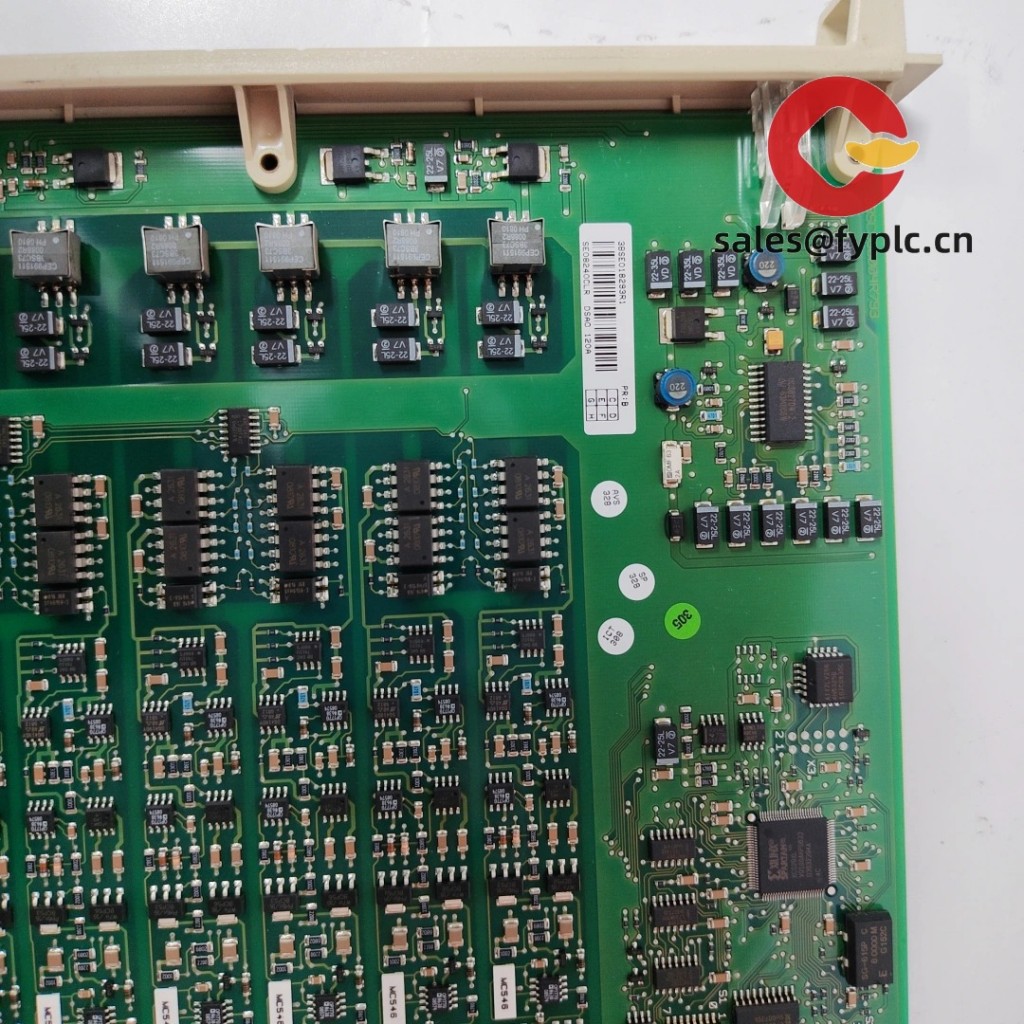

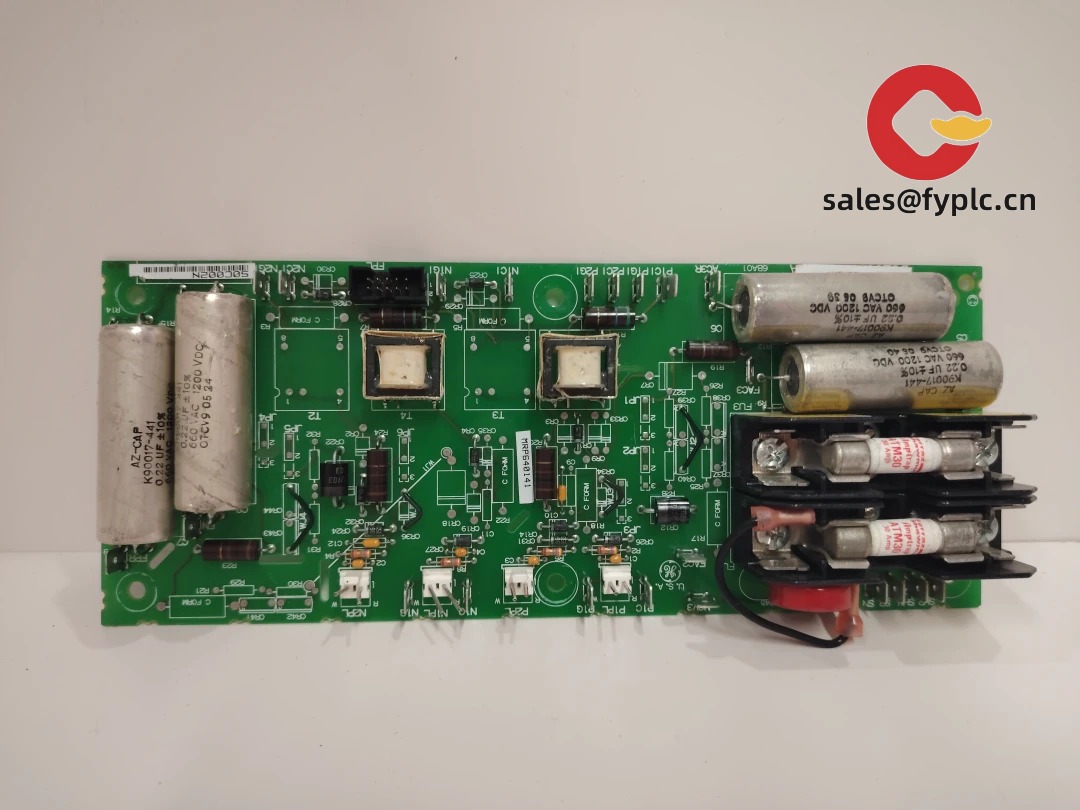

GE DS200FSAAG2ABA Field Supply Amplifier Board – Stable field control for GE DC drives and EX2000/Mark V excitation

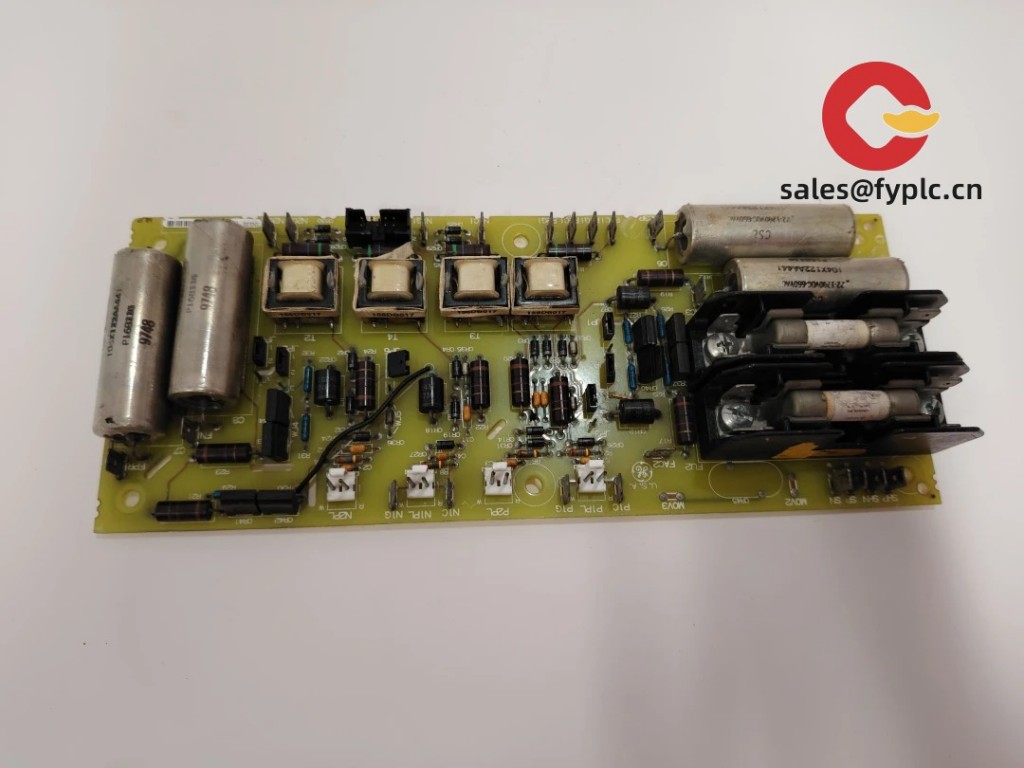

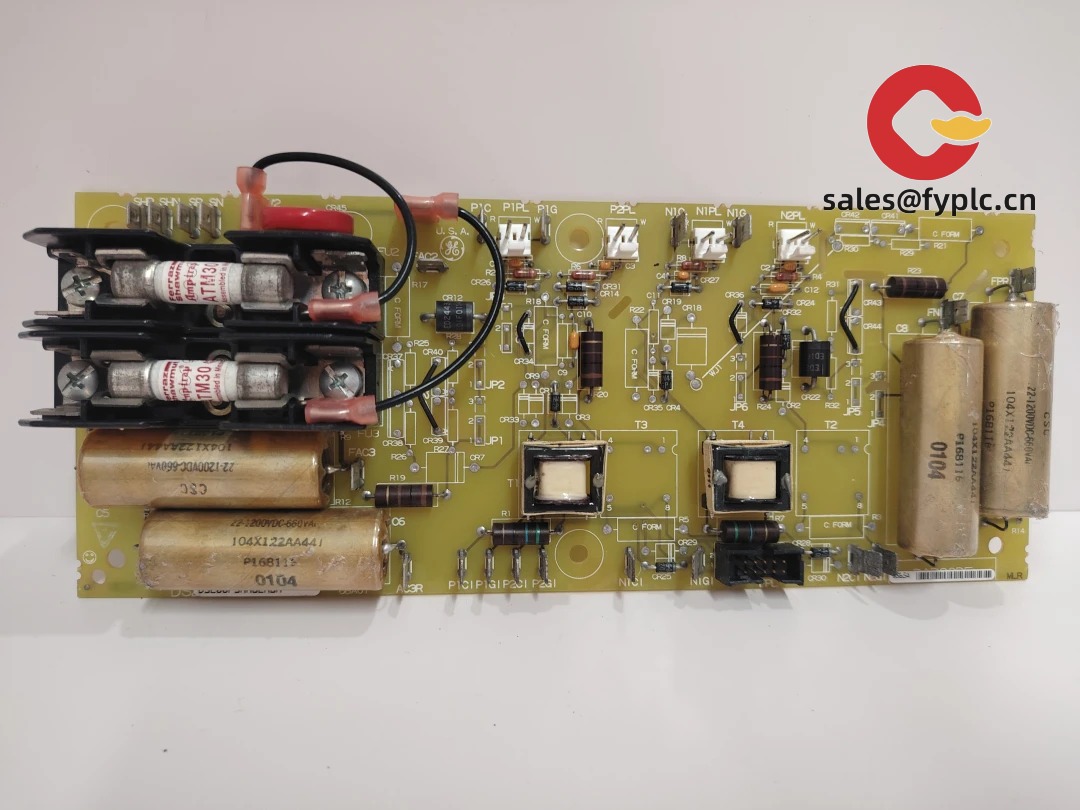

The GE DS200FSAAG2ABA is a Field Supply Amplifier Board designed to regulate and protect the field circuit in GE DC drives (like DC2000) and turbine excitation systems (EX2000/Mark V). From my experience, this board is the workhorse behind smooth field current/voltage control: it conditions feedback, enforces ramping and limits, and hands off clean control signals to the SCR bridge firing circuits. If you’re dealing with unstable field regulation, nuisance trips, or aging hardware, this model is a straight, drop-in path back to reliable operation.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment method: 50% advance payment; full payment for delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Precision field regulation – Conditions field current/voltage feedback and drives stable control of the SCR field bridge for smooth motor/exciter response.

- G2 variant alignment – The G2 hardware variant typically matches higher-current field circuits used in specific GE frames; helpful when standard FSA boards run out of headroom.

- Status and diagnostics – Onboard indicators and test points make it easier to verify loop health, forcing, and ramp behavior during commissioning.

- Protection functions – Supports field loss, overcurrent, and controlled ramp-down logic to safeguard the bridge and connected machine.

- Backplane integration – Interfaces directly with SDCC/Mark V core control via ribbon/backplane connectors; no fieldbus configuration required.

- Service-friendly tuning – Typically provides jumpers/trim settings for loop gains and limits, easing retrofit or replacement in existing cabinets.

- Drop-in replacement – DS200FSAAG2ABA is a plug-in board; replacement usually requires no cabinet rework when the existing harnessing is intact.

- Revision practicality – “ABA” denotes a specific hardware/firmware revision set; replacing with the same or a later compatible letter revision is common practice, but it’s wise to cross-check against your drive/exciter bill of material.

Technical Specifications

| Brand / Model | GE / DS200FSAAG2ABA |

| HS Code | 8538.90 (Parts for electrical control/distribution equipment) |

| Power Requirements | Supplied by drive/Mark V backplane (typically +5 VDC logic, ±15 VDC analog rails) |

| Dimensions & Weight | Standard DS200 plug-in board format; approx. 330 × 280 mm; ~0.6 kg (typical) |

| Operating Temperature | 0 to +60 °C (typical cabinet environment) |

| Signal Input/Output Types | Analog feedback (field current/voltage), low-level control outputs to SCR firing circuitry, discrete status/protection signals |

| Communication Interfaces | Ribbon/backplane connectors to SDCC/Mark V core; no external fieldbus |

| Installation Method | Plug-in PCB, secured with stand-offs/screws; mates to existing harnesses and backplane connectors |

Note: DS200 boards are typically non-conformal coated. If your environment requires coated hardware, the DS215 series variants are usually the coated equivalents—let us verify part-level compatibility before ordering.

Application Fields

- GE DC2000 and legacy DC drive systems controlling large DC motors in metals, paper, mining, and test stands.

- GE EX2000/Mark V excitation cabinets on gas and steam turbines, where stable field regulation is critical for generator performance.

- Retrofit projects replacing aging FSA boards to reduce field instability, flicker, and nuisance trips after thermal cycling or connector wear.

A maintenance lead at a steel mill told us the swap to DS200FSAAG2ABA “leveled out a stubborn field ripple we’d been chasing for months,” and—maybe more importantly—cut their weekly nuisance resets to zero.

Advantages & Value

- Reliability – Known-good performance in heavy-duty environments; component selection and filtering appear optimized for field-loop stability.

- Compatibility – Designed for GE Mark V/EX2000/DC2000 ecosystems; harnessing and backplane fit are typically straightforward.

- Cost savings – Extends system life without a full drive/exciter upgrade; reduces downtime from intermittent field regulation issues.

- Supportability – We can assist with part matching (G2 variant, ABA revision), jumper positions, and baseline tuning to speed commissioning.

Installation & Maintenance

- Cabinet environment – Install in a clean, ventilated enclosure that meets the original GE cabinet standards. Maintain adequate airflow; avoid hot spots near SCR heatsinks.

- Wiring & seating – Power down fully and allow DC bus to discharge. Use ESD protection. Reseat ribbon/backplane connectors firmly; inspect for bent pins or oxidized contacts.

- Jumper/trim checks – Verify jumper positions and any gain/limit trimmers against your site configuration notes or drive/exciter prints before energizing.

- Commissioning – Monitor field current rise using cabinet test points. You might notice that a slow, predictable ramp indicates healthy loop dynamics; sudden steps typically point to mis-scaling.

- Routine care – Every 6–12 months, blow out dust with dry air, check connector retention, and log key parameters (field current, ripple). Firmware/parameter alignment with the SDCC/Mark V core should also be reviewed after any board change.

- Safety – The field circuit stores energy; confirm zero energy state and lockout/tagout. Avoid probing live unless procedures allow and you’re using rated instruments.

Quality & Certifications

- Typically supplied to systems that comply with CE marking requirements when installed as part of the complete drive/excitation cabinet.

- UL recognition applies at the cabinet/system level for GE drives/exciters; the board is a component within that assembly.

- RoHS conformity may vary by manufacturing lot and vintage; we can confirm on request by part/serial.

- Warranty: 365 days (repair/replace) from delivery.

Reviews

There are no reviews yet.