Description

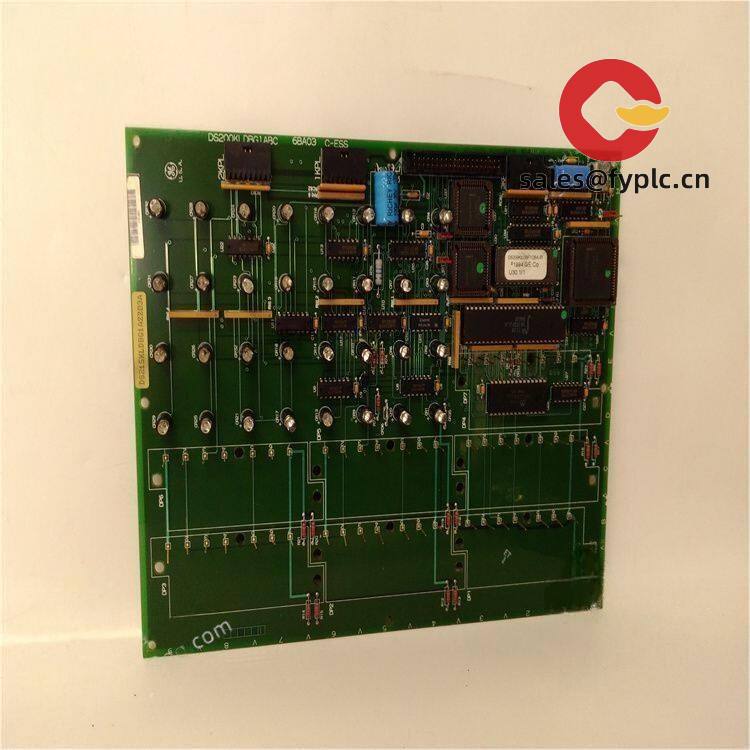

GE DS200KLDBG1ABC LED Display Board – Status and keypad display interface for Mark V / GE industrial drive panels

The GE DS200KLDBG1ABC is an LED display board used in GE Mark V Speedtronic and related GE industrial drive/excitation panels. It handles the visual status display and front-panel keypad interaction, making day‑to‑day operation and diagnostics straightforward for maintenance teams. One thing I appreciate is how this board integrates cleanly via ribbon cables to the controller assembly—no extra field wiring or external comms to worry about. The “ABC” suffix indicates a later hardware revision within the KLDBG1A family, which typically means incremental component updates and improved reliability in many cases.

From my experience, this model is chosen when plants want a like‑for‑like replacement that just drops into the existing panel, minimizing downtime. A maintenance engineer recently told us, “We swapped in the KLDBG1ABC during a short outage—display came up immediately, and the operators were back on familiar screens within minutes.”

Order Placement Process & Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- LED status and numeric display: Clear, high‑visibility indicators for alarms, modes, and numeric values typically used by operators.

- Keypad interface support: Works with the panel keypad to navigate menus, acknowledge alarms, and input setpoints.

- Direct ribbon-cable connection: Internal harnessing to the controller/backplane simplifies installation—no external comm ports required.

- Drop‑in replacement: Designed for DS200/Mark V cabinets, reducing commissioning time and risk.

- Revision “ABC” hardware: Later revision within the KLDBG1A series that, in many cases, improves component robustness and availability.

- Service-friendly layout: You might notice labeled connectors and test points that make troubleshooting faster.

Technical Specifications

| Brand / Model | GE DS200KLDBG1ABC (LED Display Board, KLDBG1A series) |

| System Compatibility | GE Mark V Speedtronic and selected GE DS200‑based drive/excitation panels (internal display/keypad interface role) |

| HS Code | 8538.90 (Parts suitable for the apparatus of heading 8535/8536/8537) |

| Power Requirements | Typically 5 VDC logic supply from backplane; power draw commonly < 5 W |

| Operating Temperature | 0 to 60 °C (typical cabinet rating; ensure adequate ventilation) |

| Signal Input/Output Types | LED drivers and display segments; keypad scan/return lines; TTL‑level logic interfaces via internal ribbon connectors |

| Communication Interfaces | Internal only (ribbon cable to controller/logic board); no external field comms on this module |

| Installation Method | Mounts inside the panel with standoffs; mates to backplane/logic via keyed ribbon connectors; ESD‑safe handling required |

Application Fields

- Gas and steam turbine control panels using GE Mark V Speedtronic hardware

- Industrial drive and excitation systems where local LED indication and keypad input are required

- Power generation, oil & gas, and process industries standardizing on GE DS200‑series controls

- Lifecycle extensions and field spares for legacy GE cabinets needing form‑fit‑function display modules

Advantages & Value

- Reliability: Robust LED indication and stable keypad scanning help reduce nuisance faults, especially in older cabinets.

- Compatibility: Fits the KLDBG1A family footprint; typically works without code changes when replacing the same series.

- Lower downtime: Drop‑in mechanical fit and keyed connectors keep swap time short during planned outages.

- Cost control: Extends service life of installed Mark V panels—often a more economical route than a full upgrade.

- Supportability: Clear labeling and standard GE ribbon interfaces make OEM‑style troubleshooting familiar to technicians.

Installation & Maintenance

- Cabinet environment: Install in a clean, dry, ventilated panel. Maintain ambient within the cabinet’s specified temperature range.

- Wiring & connectors: Use ESD precautions. Seat ribbon cables fully; follow keying to avoid reversed connections. Verify strain relief.

- Mounting: Secure to standoffs/guides. Avoid mechanical stress on the display segments and headers.

- Power-up checks: After installation, verify 5 VDC logic supply is within tolerance and inspect LED test sequences if available.

- Routine care: Dust with dry, non‑static brushes; check connector oxidation annually. No routine calibration is typically required.

- Firmware: This board usually has no field‑upgradable firmware; updates, if any, are handled at the controller level.

- Safety: Isolate power before service. Follow site lockout/tagout procedures.

Quality & Certifications

- Typically used within CE‑compliant cabinets; components commonly meet UL/CSA recognition at the system level

- RoHS status varies by production date and revision; many later boards trend toward RoHS‑compliant components

- 365‑day warranty coverage as stated above

- Each unit can be function‑tested prior to dispatch on request

If you’re replacing an earlier KLDBG1A variant, share your current part/revision and cabinet type. We’ll double‑check ribbon mappings and mounting hardware so your swap is as quick and uneventful as it should be.

Reviews

There are no reviews yet.