Description

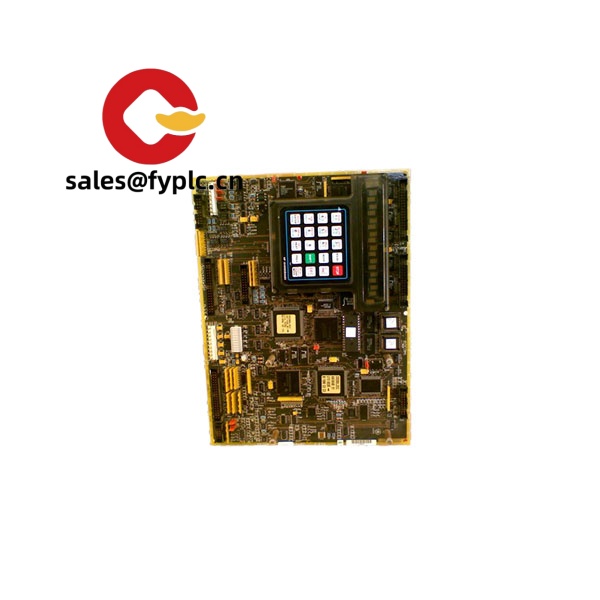

GE DS200LDCCH1AGA – LDCC drive control/LAN board for GE industrial drive systems

The GE DS200LDCCH1AGA is an LDCC (LAN Drive Control) board used across GE’s legacy DC/AC drives and excitation platforms. From my experience, it’s the card that quietly keeps the system coordinated—managing internal drive communications, reference processing, and supervisory diagnostics. If you’re maintaining a DC2000, AC2000 or related GE platform, this is typically the board you swap to recover from communication faults or erratic control behavior without touching the power section.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: In stock typically ships in 1 week; not more than 1 month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- LDCC platform – Microprocessor-based control managing internal drive LAN and supervisory logic for GE drive systems.

- Internal drive communications – Handles GE proprietary backplane/LAN traffic; not standard Ethernet, which helps avoid plant network conflicts.

- Drop-in replacement – Plugs into the DS200 rack position with existing card guides; no external field wiring on the board itself.

- Serviceable firmware – Socketed firmware (in many cases) allows version control and matching to your installed base.

- Status indication – Onboard LEDs typically provide heartbeat/fault cues for quick bench checks.

- Ruggedized for cabinet use – Designed for electrical noise found in large drives and exciters; stable operation in most industrial cabinets.

Technical Specifications

| Brand / Model | GE DS200LDCCH1AGA (LDCC drive control/LAN board) |

| HS Code | 8538.90.00 – Parts for switching/control apparatus |

| Power Requirements | Supplied by drive backplane low-voltage (typically +5 VDC). No external supply needed. |

| Operating Temperature | Cabinet ambient 0–40°C typical; non-condensing environment |

| Signal I/O Types | Internal digital/serial backplane signaling; no direct field I/O terminals on the board |

| Communication Interfaces | GE drive LAN/backplane buses; service/diagnostic headers may be present depending on revision (not Ethernet) |

| Installation Method | Plug-in PCB for DS200-format rack position; secured with card guides and fasteners; ESD-safe handling required |

| Form Factor / Weight | DS200 plug-in board; compact control card, typically under 0.5 kg |

Application Fields

You’ll most often find the DS200LDCCH1AGA in GE DC/AC variable-speed drives and excitation systems where reliable internal communications are critical. Typical use cases include:

- Metals processing (rolling lines, coilers) using GE DC2000/AC2000 drive families

- Pulp & paper drives for winders and calenders with tight speed coordination

- Power generation exciters (EX-series) where stable control LAN matters

- Industrial test stands and heavy machinery retrofits extending the life of GE legacy systems

One maintenance engineer told us the board “seems to be the no-drama fix” when a healthy power section starts throwing internal comms faults—swap LDCC, match firmware, and the line is back up in under an hour.

Advantages & Value

- Reliability – Proven hardware for GE legacy platforms; in many cases, the fastest path to restore production.

- Compatibility – Designed for DS200 architecture; typically works with installed SDCC/control boards when firmware is matched.

- Cost control – A targeted card replacement avoids the expense and downtime of a full drive upgrade.

- Support – We help identify firmware revisions and set basic jumper defaults so commissioning stays predictable.

Installation & Maintenance

- Environment – Install in a clean, ventilated cabinet. Maintain ambient 0–40°C and keep clear airflow around cards.

- Safety – Isolate power, wait for DC bus discharge, and observe ESD precautions. Handle by edges; avoid touching components.

- Swap procedure – Record existing jumpers/links, note firmware part numbers, and back up drive parameters where applicable. Seat the card fully into guides and secure.

- Commissioning – Verify firmware compatibility with your SDCC/control board; clear historical faults and run self-tests before returning to service.

- Routine care – Quarterly cabinet dust removal (dry air, low pressure), visual inspection for connector oxidation, and periodic firmware review to keep versions aligned across spares.

Quality & Certifications

- Manufactured under GE quality systems; typically used within CE/UL compliant drive systems

- Units are functionally checked before dispatch to reduce on-site trial time

- Warranty: 365 days hardware warranty

Related/Supporting Components (commonly paired)

- GE DS200SDCCG1A – Drive control board that typically interfaces with the LDCC over the internal backplane.

- Firmware/EPROM sets for DS200LDCCH1 – Used to match site firmware revisions and maintain compatibility across multiple drives.

- Backplane connectors and card guides – Replacement hardware to ensure reliable seating and signal integrity in older cabinets.

If you’d like, share your drive family (e.g., DC2000/AC2000/EX-series) and current firmware IDs—we can double-check compatibility and prepare a board that’s ready to slot in with minimal adjustment.

Reviews

There are no reviews yet.