Description

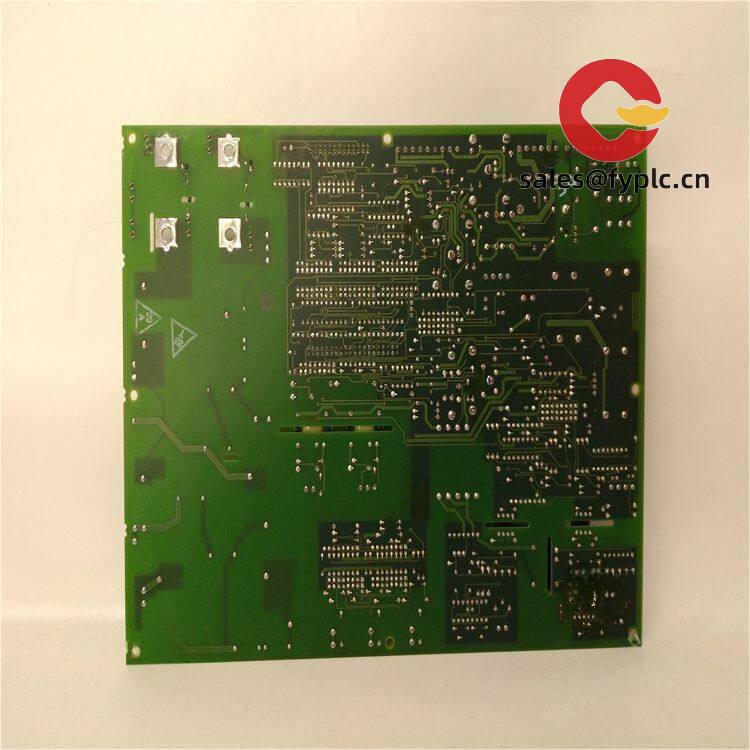

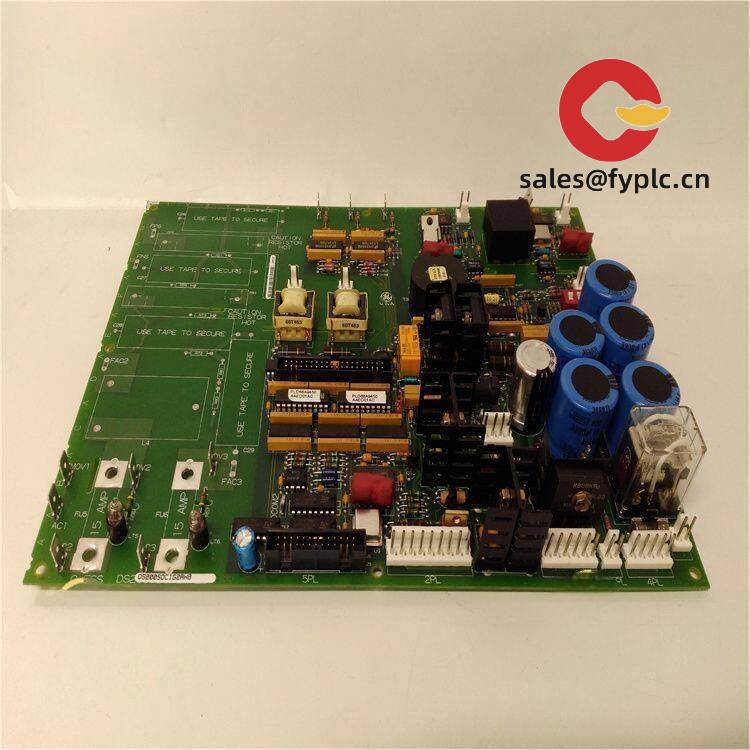

GE DS200SDCIG2AHB – Signal Conditioner/Isolator Board for Mark V Turbine Control

The GE DS200SDCIG2AHB is an SDCI series signal conditioning and isolation board used in Mark V Speedtronic control systems. From my experience, this board sits in the I/O path to clean, isolate, and scale field signals before they reach the control core. You might notice that plants typically use the G2 variant when the I/O map calls for a specific mix of analog channels and isolation, making it a straight drop‑in for existing DS200-based racks.

Our Order Process & Guarantees

- Warranty: 365 days

- Lead Time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Shipping: FedEx, UPS, DHL (express worldwide)

Key Features

- Galvanic isolation – Helps break ground loops and reduce noise from field wiring, which in many cases cuts nuisance trips.

- Signal conditioning – Scales and filters analog inputs so the Mark V core receives stable, usable values.

- G2 variant compatibility – Aligned with Mark V I/O maps that require the G2 board option; typically a drop‑in replacement for DS200SDCIG2 assemblies.

- Backplane integration – Interfaces through GE’s Mark V backplane and ribbon headers for quick swap‑out during outages.

- Field-proven design – Used across gas/steam turbine controls where steady analog performance is crucial.

- Serviceable hardware – Jumpers and test points allow practical field checks and, where applicable, channel configuration.

Technical Specifications

| Brand / Model | GE – DS200SDCIG2AHB (SDCI Board, G2 variant) |

| HS Code | 8538.90 (Parts suitable for use with industrial control apparatus) |

| Power Requirements | Supplied via Mark V backplane; typically uses +5 VDC and auxiliary rails provided by the rack |

| Operating Temperature | Control cabinet environment; typically 0 to +60 °C when installed per GE panel guidelines |

| Signal I/O Types | Isolated analog signal conditioning channels (voltage/current scaling and filtering; factory-configured) |

| Communication Interfaces | Proprietary Mark V backplane edge connectors and ribbon headers (board‑to‑board) |

| Installation Method | Plug‑in PCB for Mark V racks; secured with standard card guides and fasteners |

Application Fields

This board is commonly found in GE Mark V Speedtronic systems across:

- Gas and steam turbine control in power generation

- Oil & gas compressor trains and process turbines

- Industrial drives and balance‑of‑plant loops where stable analog inputs are essential

One thing I appreciate is how it stabilizes low‑level analog signals coming from long cable runs. A maintenance lead at a combined‑cycle plant told us nuisance analog spikes dropped noticeably after swapping in a healthy SDCI board during a hot‑section outage.

Advantages & Value

- Reliability: Designed for harsh cabinet environments; typically very low failure rates when ventilation is adequate.

- Compatibility: Matches DS200 Mark V architecture; avoids re‑engineering I/O or logic.

- Downtime reduction: True plug‑replace form factor keeps outage windows tight.

- Cost control: Refurb/exchange programs available in many cases; helps manage lifecycle budgets.

- Technical support: We can assist with cross‑checks for G1 vs G2 usage and jumper settings prior to shipment.

Installation & Maintenance

- Cabinet standards: Install in a clean, dry Mark V rack with adequate airflow; keep ambient within control room spec.

- Wiring: Verify ribbon and backplane connectors are fully seated; avoid cable strain and sharp bends.

- ESD safety: Handle with a grounded wrist strap; store in anti‑static packaging.

- Jumpers/adjustments: Confirm any required jumper positions or potentiometer trims per your site’s I/O list.

- Routine checks: Visual inspection each outage; clean dust with dry, oil‑free air; reseat connectors if needed.

- Records: Note serial/revision (AHB) in maintenance logs to keep the spare strategy consistent.

Quality & Certifications

- Quality system: Typically supported under ISO 9001 quality controls for manufacturing and repair.

- Compliance: CE/UL conformity applies at the system level for Mark V panels; board‑level markings may vary on legacy hardware.

- Environmental: RoHS applicability can vary for original‑era parts; replacements are screened for functional equivalence and safety.

- Warranty: 365 days from delivery.

If you can share your current panel part list or a photo of the installed SDCI slot, we’ll double‑check the DS200SDCIG2AHB revision fit and confirm lead time. In most cases, that pre‑check saves a truck roll once the unit arrives.

Reviews

There are no reviews yet.