Description

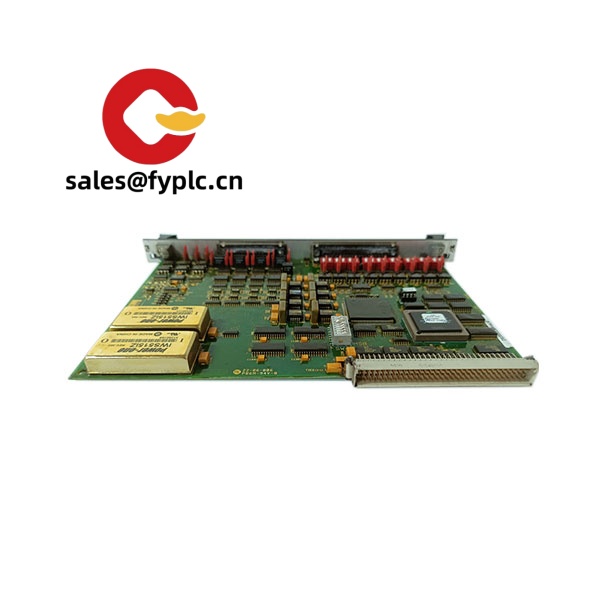

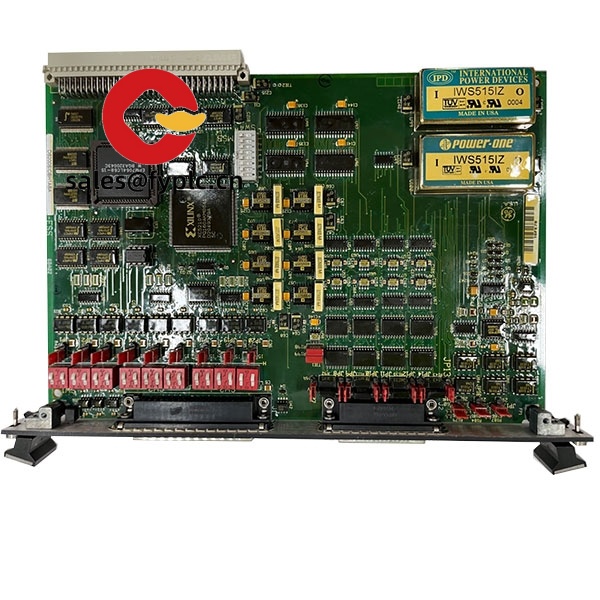

GE DS200SIOBH1ACA – Serial I/O Board for GE Mark V / Innovation Series Drives

The GE DS200SIOBH1ACA is a Serial Input/Output (SIOB) board used widely in GE Mark V and Innovation Series drive and excitation platforms. From my experience, this board handles a mix of serial links and local I/O management, acting as a bridge between the controller and field signals through associated terminal boards. If you’re maintaining EX2000/LS2100 or comparable GE drive systems, this model is typically a drop‑in, like‑for‑like replacement that helps restore stable communications and clean I/O behavior with minimal rework.

Our Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- SIOB functionality – Manages serial communications and local I/O buffering so the main control board can focus on core drive/excitation logic.

- Revision ACA – A later hardware revision in the DS200SIOBH1 family, which typically includes incremental reliability and layout refinements.

- Backplane-powered – Draws regulated rails (commonly 5 VDC logic and ±15 V analog) through the rack; no separate PSU wiring in most cases.

- System compatibility – Designed for GE Mark V/Innovation Series racks and associated terminal boards; you might notice shorter commissioning time when replacing same-revision units.

- Serviceability – Headers and connectors are laid out for quick inspection; from field feedback, reseating ribbon cables typically solves intermittent channel faults.

- Coating convention – DS200 series boards are usually uncoated (while DS215 variants are conformal coated), which helps when troubleshooting or component-level repair.

Technical Specifications

| Brand / Model | GE / DS200SIOBH1ACA |

| HS Code | 8538.90 (Parts suitable for switchgear/controls) |

| Power Requirements | Backplane supplied; typically 5 VDC logic and ±15 V analog rails |

| Dimensions & Weight | Approx. 280 × 203 mm (11 × 8 in); ~0.5 kg |

| Operating Temperature | 0 to +60 °C (cabinet conditioned per GE drive guidelines) |

| Signal Input/Output Types | Mix of discrete and analog I/O via terminal boards; supports serial channels; analog ranges commonly ±10 V or 4–20 mA (system-dependent) |

| Communication Interfaces | Onboard serial (e.g., RS-232/RS-485 where implemented), ribbon/backplane interconnects to controller and TBs |

| Installation Method | Plug-in rack card; secured with standoffs; cabled to associated terminal boards per slot map |

Application Fields

You’ll typically find the DS200SIOBH1ACA in GE drive/excitation cabinets across:

- Power generation – excitation systems and auxiliary drives in gas/steam plants

- Metals & mining – mill stands, hoists, conveyors requiring robust serial I/O links

- Oil & gas – compressor and pump drives where stable field I/O is critical

- Marine & heavy industry – propulsion auxiliaries and high-inertia motor control

Advantages & Value

- Form/Fit/Function – Direct mechanical and electrical fit in DS200 rack slots reduces downtime.

- Compatibility – Works with common GE terminal boards like DS200TBCAG1A/DS200TBQG*, keeping wiring changes to a minimum.

- Cost control – A targeted board replacement often restores operation without a full system upgrade.

- Technical support – Clear slot mapping and labeling simplify troubleshooting; most issues trace to cabling or connector fatigue rather than board logic.

*Actual terminal board pairing depends on cabinet configuration and I/O ranges.

Installation & Maintenance

- Cabinet & environment – Install in a clean, ventilated enclosure. Maintain ambient 0–60 °C with stable AC supply to the rack.

- Wiring & grounding – Use original GE ribbon and shielded serial cables. Verify ground bonding to avoid communication noise.

- ESD safety – Handle with grounded wrist strap. De-energize the rack and wait for DC bus discharge before removal.

- Commissioning checks – Confirm slot position, connector orientation, and TB part numbers. After power-up, verify serial link health and I/O scaling in the HMI/drive tools.

- Routine care – Inspect and reseat cables annually, clean light dust with dry air, and keep firmware/config backups aligned to the board revision.

Quality & Certifications

- Manufacturer: GE (legacy industrial drives/excitation component)

- Certifications: Typically used within CE/UL-compliant systems; component-level markings may vary by build year

- Quality system: Produced under ISO 9001-based processes (manufacturer)

- RoHS: Varies with production date; many legacy DS200 boards are not RoHS

- Warranty: 365 days (supplier warranty)

Commonly Paired Components (for planning)

- GE DS200SDCCG1A – Main drive control card that the SIOB typically supports

- GE DS200TBCAG1A / DS200TBQG – Terminal boards providing field I/O terminations

- GE DS215 variants – Conformal-coated alternatives when environmental protection is required

Quick customer note: A maintenance team in a metals plant swapped in DS200SIOBH1ACA during a scheduled stop. You might notice the most time was spent on cable labeling and reseating; once in place, serial comms came up clean, and discrete inputs trended stable without further tuning. That seems to be the typical experience when the old board had intermittent connector issues.

Reviews

There are no reviews yet.