Description

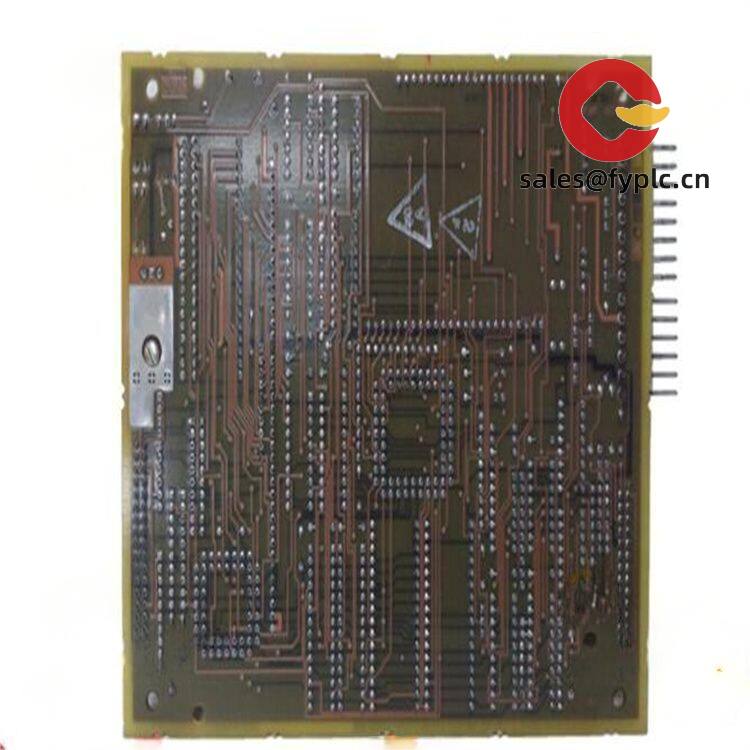

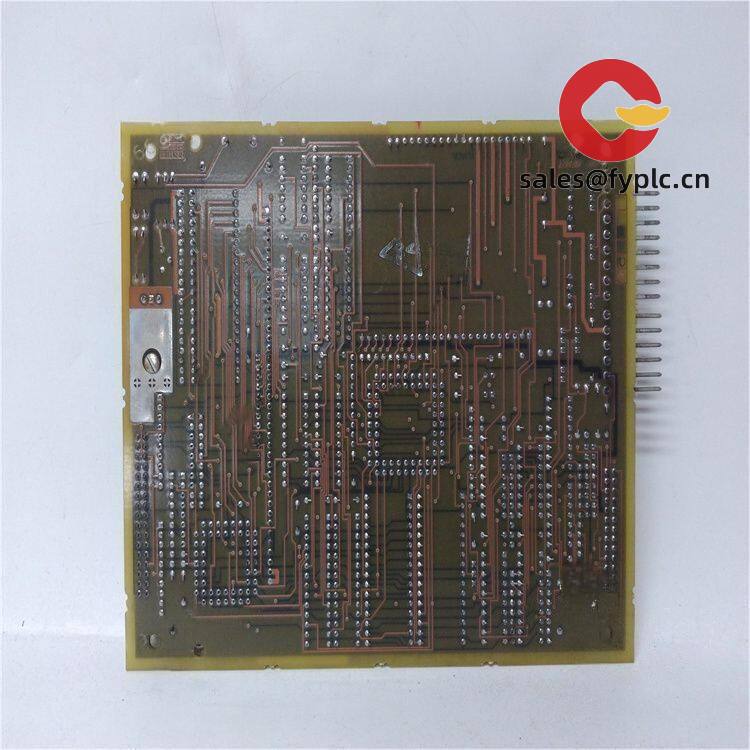

GE DS200SLCCG1AFG – LAN/Serial Communication Card for GE Series 2000 Drives and Excitation Systems

The DS200SLCCG1AFG is a GE SLCC (LAN/Serial Communications) card designed to handle drive-to-PLC/SCADA links and inter-board data exchange in GE Series 2000 platforms—typically AC2000, DC2000, and EX2000. From my experience, it’s the go‑to drop‑in when you need reliable RS‑232/RS‑485 connectivity or to restore LAN communications after a board fault. You might notice that it’s jumper/DIP configurable, which makes field setup straightforward without a laptop in many cases.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Multi‑protocol serial ports – Typically provides RS‑232 (COM1) and RS‑485 (COM2) for PLC/HMI/SCADA links.

- Drive LAN interface – Supports GE drive local communications (arcnet/DLAN+ style on applicable revisions) for inter-board data exchange.

- Drop‑in for Series 2000 frames – Designed for AC2000/DC2000/EX2000; helps minimize commissioning steps.

- Jumper/DIP configuration – Quick parameterization in the field; no special tools for basic setup.

- Status LEDs – At‑a‑glance health and activity indicators simplify troubleshooting.

- Backplane powered – Receives low‑voltage logic power from the drive rack; wiring stays tidy.

- Firmware‑dependent options – Function set can vary slightly by revision; we can help match to your site’s firmware level.

Technical Specifications

| Brand / Model | GE / DS200SLCCG1AFG |

| HS Code | 8538.90 (Parts for industrial control apparatus) |

| Power Requirements | Supplied via drive backplane; +5 VDC logic (typical), power draw < 10 W in most cases |

| Dimensions & Weight | Approx. 330 × 220 mm (13 × 8.7 in); ~0.6 kg (board only) |

| Operating Temperature | 0 to +60 °C (cabinet‑mounted, ventilated enclosure) |

| Signal I/O Types | Single‑ended RS‑232, isolated RS‑485 (typical), TTL‑level status lines, LED diagnostics |

| Communication Interfaces | COM1 (RS‑232), COM2 (RS‑485); onboard drive LAN interface depending on revision/firmware |

| Installation Method | Plug‑in PCB in the Series 2000 rack; ribbon connectors to control card; secured with standoffs |

Application Fields

This board is commonly used in heavy‑duty industrial environments where GE Series 2000 drives or exciters are installed:

- Metals and rolling mills – tying DC/AC drives into plant PLCs over RS‑485.

- Pulp & paper – reliable HMI/SCADA links for line drives across multiple sections.

- Mining and hoisting – stable communications in high‑noise electrical rooms.

- Power generation (EX2000 exciters) – coordinated control messaging and monitoring.

- Oil & gas and chemical plants – serial integration where Ethernet is not preferred.

One thing I appreciate is how tolerant the SLCC tends to be in legacy cabinets. In many cases, you can keep existing serial wiring runs and just re‑set the jumpers to match baud rate and mode.

Advantages & Value

- Low downtime – True drop‑in format; typical changeout under one hour with pre‑set jumpers.

- Backwards compatibility – Works with established Series 2000 racks; no cabinet rework.

- Cost control – Replace the failed comms card instead of upgrading the entire drive system.

- Troubleshooting clarity – Onboard LEDs and clear COM labelling make field diagnostics faster.

- Technical support – Assistance with parameter/jumper mapping to your existing SDCC firmware.

A maintenance manager who swapped this board into an EX2000 panel told us the “PLC comms came back immediately after matching the original COM2 RS‑485 settings,” which mirrors what we typically see in the field.

Installation & Maintenance

- Cabinet & environment – Mount in a clean, ventilated, IP‑rated enclosure; maintain ambient 0–60 °C and avoid condensation.

- ESD handling – Use a grounded wrist strap; handle by edges; avoid touching components and pins.

- Wiring – Keep RS‑485 as twisted, shielded pair; land shield at one end to reduce ground loops; route away from high‑power cabling.

- Jumper/DIP settings – Record original SLCC switch and jumper positions before removal; replicate baud/parity/mode on the replacement.

- Grounding – Ensure chassis bonding is intact; verify connector screws and standoffs are secure.

- Routine checks – Inspect connectors quarterly for oxidation; re‑seat ribbon cables; clean dust with dry air at low pressure.

- Firmware – Match board firmware to site expectations when possible; keep a note of revisions for spares planning.

Quality & Certifications

- Manufacturing quality – Produced to GE’s industrial quality standards; ISO 9001 quality systems typically apply at factory level.

- Compliance – CE/UL compliance is usually declared at the full drive/system level; board conforms to the platform’s design requirements.

- RoHS – RoHS status can vary by production year/revision; we can check the specific unit’s marking on request.

- Warranty – 365‑day coverage as part of our supply commitment.

Related/Supporting Components

For planning spares or complete repairs, customers often pair the DS200SLCCG1AFG with:

- DS200SDCC (Drive Control Card) – the main control processor board interfacing to SLCC.

- DS200SPCB I/O or terminal boards – field I/O termination in Series 2000 racks.

- Shielded serial cabling and ARCNET/DLAN+ media (where used) – to maintain noise immunity.

Reviews

There are no reviews yet.