Description

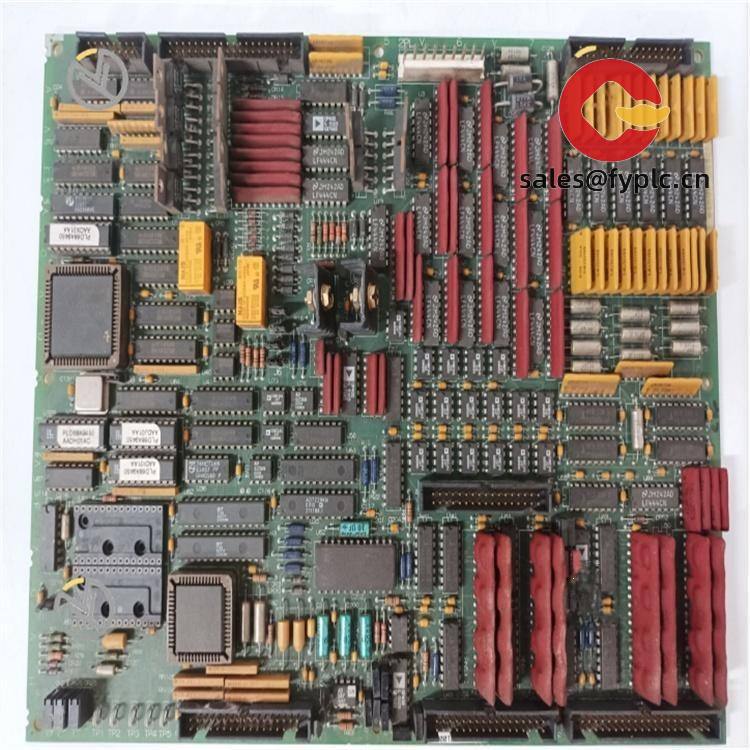

GE DS200TCQAG1BHF Digital I/O Module – Reliable Discrete Signal Interface for Mark V Controls

The DS200TCQAG1BHF is a GE DS200-series digital input/output module commonly used in Speedtronic Mark V turbine control cabinets. From my experience, this board is the workhorse for discrete signals—bringing contact inputs into the controller and driving relay/solenoid outputs via the cabinet’s terminal boards. It typically sits in the Mark V core and communicates through the backplane, so you get stable, low-latency updates for sequencing, permissives, and protective interlocks.

One thing I appreciate is how straightforward integration tends to be when replacing like-for-like hardware. You might notice that the DS200TCQAG1BHF supports triplicated architectures (R/S/T cores) in many Mark V installations, helping maintain deterministic behavior and fault tolerance in critical applications.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express Options: FedEx, UPS, DHL

- Documentation & QA: Functional check and visual inspection report typically provided before shipment

Key Features

- Digital input scanning – Processes cabinet contact inputs for status, permissives, and alarms, usually with wetting voltage supplied from the I/O panel.

- Relay/driver outputs – Provides discrete outputs to relays and solenoids via the cabinet’s terminal boards; ideal for trip, bypass, and sequencing commands.

- Backplane integration – Interfaces directly to the Mark V backplane for deterministic updates without external fieldbus gateways.

- TMR-friendly design – In many cases used across R/S/T cores to support triplicated voting and higher availability in turbine applications.

- Serviceable layout – Clear test points and connectors help maintenance teams troubleshoot faster; replacement is typically a simple board swap.

- Compatibility – Designed for the DS200/Mark V ecosystem; commonly paired with GE termination boards depending on cabinet build.

“We swapped a faulty TCQA in our gas turbine cabinet with a DS200TCQAG1BHF spare. The I/O scanned clean on first power-up, no strange debounce issues, and it aligned with the R/S/T cores as expected.” — Maintenance Supervisor, 250 MW CCGT

Technical Specifications

| Parameter | Details |

|---|---|

| Brand / Model | GE DS200TCQAG1BHF |

| Product Type | Digital Input/Output (I/O) Module for Mark V |

| HS Code | 8538.90 (Parts suitable for apparatus of 85.37) |

| Power Requirements | Typically 5 VDC supplied from the Mark V backplane (board-level, low power) |

| Operating Temperature | 0 to 60 °C (control cabinet environment; non-condensing) |

| Signal Input/Output Types | Discrete contact inputs and relay/driver outputs via cabinet terminal boards (exact voltage/ratings depend on the paired termination hardware) |

| Communication Interfaces | Mark V backplane interface; internal ribbon/cable connectors to termination boards; no external fieldbus on the card itself |

| Installation Method | Plug-in PCB for GE Mark V racks; connects to cabinet terminal/termination boards with ribbon or harness assemblies |

| Form Factor | Single-slot board within the DS200/Mark V core (standard GE mounting hardware) |

Application Fields

- Gas and steam turbine control (Speedtronic Mark V cabinets)

- Balance-of-plant discrete interlocks, permissive chains, and trip circuits

- Power generation, oil & gas, and industrial cogeneration sites needing deterministic discrete I/O

- Retrofits or maintenance replacements in existing DS200-based systems

Advantages & Value

- Drop-in compatibility – Matches the Mark V ecosystem; minimizes commissioning time and risk during maintenance windows.

- Operational reliability – Stable digital signal processing; supports TMR architectures where deployed.

- Cost control – Extends system life without forcing a full platform upgrade; often the most economical path for plants running well on Mark V.

- Documentation and support – We typically provide handling guidelines and test results; technical guidance to align with your cabinet configuration.

Installation & Maintenance

- Environment – Install in a clean, dry, well-ventilated control cabinet. Avoid corrosive atmospheres; maintain non-condensing humidity.

- Cabinet standards – Use the designated Mark V rack position. Ensure correct standoffs and backplane alignment; do not force connectors.

- Wiring – Field I/O lands on the cabinet terminal boards; verify ribbon/harness orientation and locking. Output ratings depend on the termination board used.

- Safety – Isolate power and de-energize field circuits. Follow ESD precautions (strap, mat, antistatic packaging).

- Commissioning – After installation, run I/O cross-checks in the HMI/tooling, confirm contact debounce, and validate permissives/interlocks in each core.

- Routine care – Periodic visual inspection, connector reseat if needed, and dust removal with dry, oil-free air. No user firmware updates on this card in most cases; configuration is handled in system software.

Quality & Certifications

- Manufacturing quality – Typically produced under ISO 9001 quality systems (varies by lot and manufacturer period).

- Compliance – Mark V systems in the field often meet CE/UL/CSA requirements; board-level markings can vary by revision. RoHS exemptions may apply for legacy hardware.

- Warranty – 365-day warranty coverage as stated above.

Related/Supporting Components

Depending on cabinet design, this module commonly interfaces with GE termination boards and ribbon/harness assemblies in the DS200/Mark V family. You’ll often see it paired with digital I/O terminal boards in the same enclosure to handle wetting voltage, fusing, and field isolation. If you share your cabinet BOM or photos, we can match the exact companion boards and cable part numbers.

Reviews

There are no reviews yet.