Description

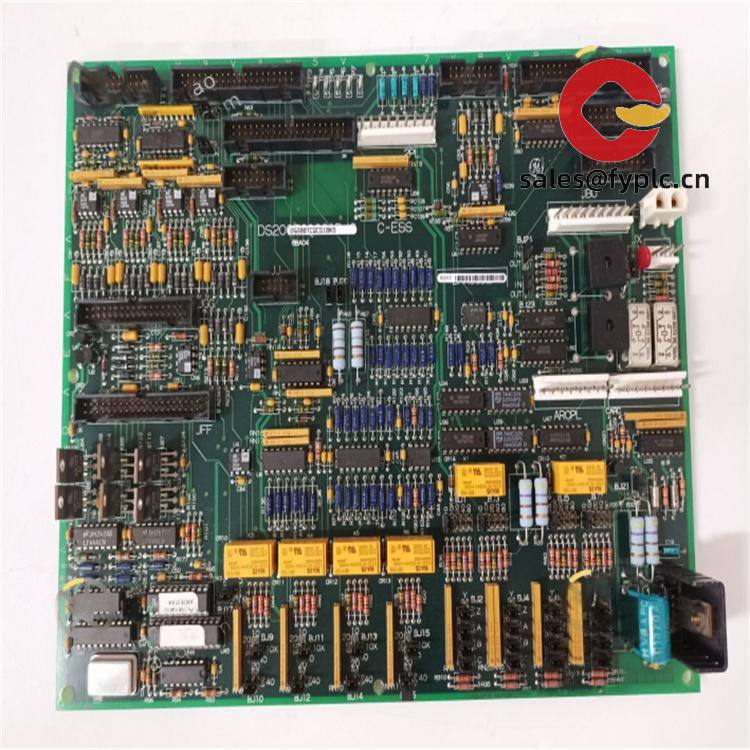

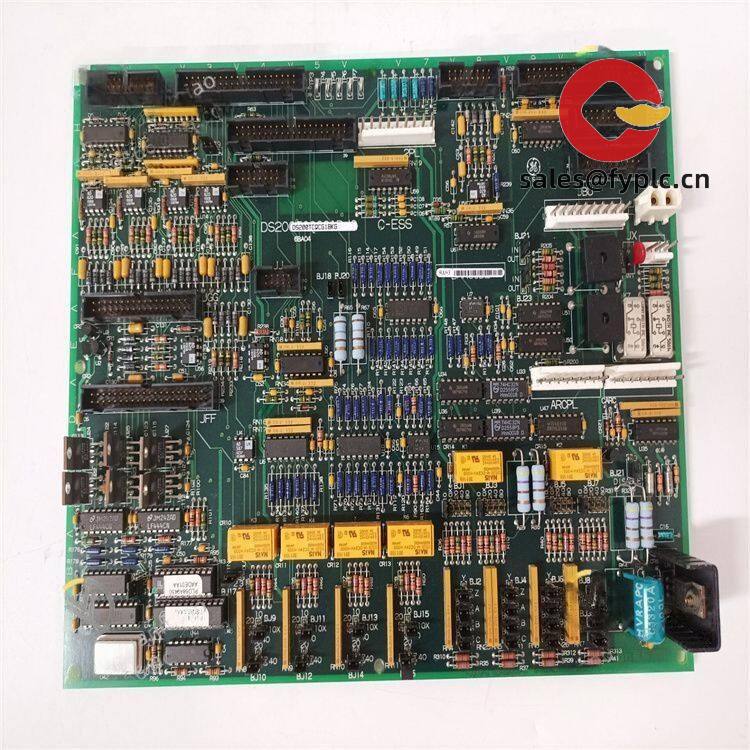

GE DS200TCQCG1BKG – Mark V I/O Control Module for Reliable Turbine System Signal Conditioning

The GE DS200TCQCG1BKG is a TCQC-series control board used in Mark V Speedtronic systems, typically sitting in the <Q> core for mixed signal conditioning and sequencing tasks. From my experience, this board helps route and buffer a combination of analog and discrete signals through the Mark V backplane, keeping turbine control logic stable and repeatable. One thing I appreciate is how it drops straight into the existing rack and keeps wiring untouched—usually it’s a quick, low-risk swap that gets a down unit back up fast.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week when in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Native Mark V compatibility – Designed for GE Speedtronic Mark V racks, allowing straightforward plug-in replacement without field rewiring.

- Mixed I/O signal conditioning – Handles typical analog and discrete signal paths inside the <Q> core to support sequencing and control logic.

- Backplane integration – Interfaces via Mark V proprietary backplane connectors; no external fieldbus configuration required.

- Service-friendly design – In many cases, site-specific firmware (EPROMs) can be transferred from the old board to maintain the exact configuration.

- Drop-in reliability – Typically helps restore failed channels or intermittent I/O behavior without touching process wiring.

Technical Specifications

| Brand / Model | GE – DS200TCQCG1BKG (TCQC series) |

| HS Code | 8538.90 (Parts for industrial control apparatus of 8537) |

| System Compatibility | GE Speedtronic Mark V; typically used within the <Q> core I/O rack |

| Power Requirements | Backplane-supplied low-voltage DC rails (5 V and ±15 V typical within Mark V cabinets) |

| Dimensions & Weight | Standard DS200 board form factor; approx. 0.4–0.6 kg (board only) |

| Operating Temperature | Typically 0–60°C inside conditioned control cabinets; 5–95% RH non‑condensing |

| Signal I/O Types | Mixed analog/discrete signal conditioning via Mark V backplane and terminal boards |

| Communication Interfaces | Proprietary Mark V backplane connectors; no external fieldbus port on board |

| Installation Method | Plug-in PCB; secured to the rack with standoffs/screws; firmware via socketed EPROMs (site-specific) |

| Hardware Revision | BKG hardware revision within the DS200TCQCG1 family |

Application Fields

This board is used in GE Mark V platforms across gas and steam turbine control, combined-cycle plants, compressor stations, and petrochemical utilities. You might notice it most where mixed analog/discrete channels must be tightly synchronized with turbine sequencing—trip logic, permissives, and process interlocks. In many cases, replacing a weak TCQC card resolves intermittent contact feedbacks or drifting analog references that show up during starts.

Advantages & Value

- Reliability – Proven compatibility within Mark V systems reduces troubleshooting time and risk after replacement.

- Compatibility – Keeps existing terminal boards and wiring intact; firmware can be matched to site configuration.

- Cost control – A focused card-level swap typically avoids larger system interventions or extended outages.

- Supportability – Technicians are familiar with the DS200 layout, which usually speeds up checks and loop verifications.

Technician feedback from a recent outage: “Swapped the DS200TCQCG1BKG, moved our EPROM set, and the nuisance discrete alarms cleared on the next start. No wiring changes needed.” That seems to be a common outcome when the symptoms are I/O-channel specific.

Installation & Maintenance

- Environment – Install in a clean, conditioned Mark V cabinet with adequate ventilation; follow cabinet grounding and bonding practices.

- Handling – Observe ESD precautions; power down the rack and wait for discharge before removal/installation.

- Firmware – If applicable, transfer site EPROMs to the new board and verify jumpers/switches match the previous unit.

- Wiring – No field wiring lands directly on the board; connections are via the backplane and terminal boards—check seating and standoffs.

- Routine care – Periodically inspect connectors, clean dust with dry air, and log any channel deviations during scheduled shutdowns.

- Post-install checks – Run self-tests and verify key permissives/alarms in the HMI before returning to service.

Quality & Certifications

- Manufactured to OEM standards; typically integrated in CE/UL-compliant Mark V panels

- Produced under ISO 9001 quality systems (manufacturer-level)

- RoHS compliance may not apply to legacy designs; supplied unit tested functionally

- Warranty: 365 days

Commonly Paired Components

Often found alongside DS200TCQAG1 (analog input), DS200TCQBG1 (digital/relay I/O), and related Mark V terminal boards. If you’re troubleshooting a wider I/O chain, it’s practical to review these boards together.

Reviews

There are no reviews yet.