Description

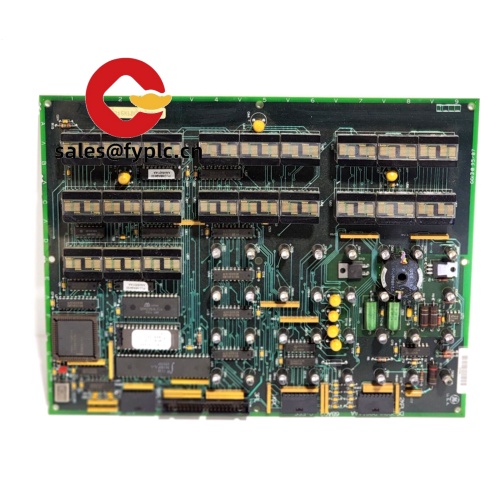

GE DS200TCRAG1ACC – Thermocouple Input Board for Speedtronic Mark V Temperature Acquisition

The GE DS200TCRAG1ACC is a Thermocouple Input Board engineered for Speedtronic Mark V control systems. From my experience, this board typically handles multi-channel thermocouple signals with cold-junction compensation, linearization, and fault detection, then streams clean, time-coherent temperature data to the Mark V backplane. If you’re maintaining a gas/steam turbine, HRSG, or high-temperature process line, this is one of those plug-in spares that keeps trips down and diagnostics straightforward.

Our Order Process & Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment terms: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

- Every unit is function-tested prior to shipment and packed for ESD protection

Key Features

- Thermocouple signal conditioning – Accepts low-level mV inputs from common TC types (J, K, T, E, R, S, B) for turbine and process measurements.

- Cold-junction compensation – CJC circuitry helps maintain accuracy across cabinet temperature changes.

- Linearization and fault detection – On-board processing typically provides open-circuit detection and stable scaling to engineering units.

- High-noise immunity – Input filtering and board layout designed for EMI/RFI resilience in turbine enclosures.

- Backplane integration – Direct interface to the Mark V backplane for deterministic data transfer; no external wiring beyond the terminal board.

- Field serviceability – Plug-in replacement with captive hardware; typically no recalibration required after swap.

- Status indication – You might notice service LEDs that make field diagnostics faster.

- Drop-in compatibility – Designed for Speedtronic Mark V racks with the matching thermocouple terminal board.

Technical Specifications

| Brand / Model | GE DS200TCRAG1ACC |

| HS Code | 8538.90 (Parts for electrical control apparatus) |

| Main Function | Thermocouple input/conditioning module for Speedtronic Mark V systems |

| Power Requirements | Supplied via Mark V backplane; no external power needed (typically +5 V and analog rails provided by rack) |

| Operating Temperature | 0 to 60°C typical cabinet environment; 5–95% RH non‑condensing |

| Signal Input/Output Types | Differential thermocouple inputs (Types J/K/T/E/R/S/B), cold-junction compensation; digital data to backplane |

| Communication Interfaces | Mark V backplane bus (not user-configurable I/O ports) |

| Installation Method | Plug-in PCB into Mark V rack with mating thermocouple terminal board; secured via standard board retainers |

| Form Factor | Standard DS200 board format for Speedtronic Mark V |

Application Fields

This board is commonly used wherever reliable, multi-point temperature monitoring feeds the Mark V control:

- Gas and steam turbine exhaust, bearing, and casing temperature surveillance

- HRSG and boiler tube temperature mapping

- Industrial furnaces, reformers, and kilns requiring stable high-temperature measurement

- Compressor trains and balance-of-plant thermal protection

“Swap time was under 30 minutes and our drift issue disappeared,” noted a maintenance lead at a combined-cycle plant after replacing a TCRA board during a scheduled outage.

Advantages & Value

- Reliability – Proven GE hardware with robust filtering helps avoid nuisance trips in electrically noisy rooms.

- Compatibility – Drop-in fit for Mark V with the matching terminal board; no wiring rework in most cases.

- Reduced downtime – Quick board-level replacement means faster recovery from channel faults.

- Support – From part selection to commissioning advice, we typically help verify revisions and backplane compatibility before shipment.

- Lifecycle savings – Stable temperature inputs contribute to better tuning, fewer false alarms, and less wear on the machine.

Installation & Maintenance

- Cabinet & environment – Install in a clean, ventilated Mark V enclosure. Maintain airflow and keep away from high-voltage cabling to limit induced noise.

- Wiring practices – Use matching thermocouple extension wire and correct polarity. Route TC pairs separately from power conductors; land shields at a single point to minimize ground loops.

- ESD handling – Use a grounded wrist strap, power down the rack, and allow discharge time before removal or insertion.

- Commissioning – After installation, verify each channel with a dry-well or simulator. You might notice that open-circuit detection quickly flags miswired points.

- Routine care – Periodic connector re-seating, light dust removal with dry air, and point-to-point checks during outages are usually sufficient. Firmware changes are not typically required for this board type.

Quality & Certifications

- Manufacturing quality: GE production under ISO 9001 quality systems (typical for this product family)

- UL/cUL: Generally recognized as part of the complete control panel assembly

- CE: System-level CE compliance depends on the overall Mark V cabinet configuration

- RoHS: Legacy hardware may not be RoHS; compliant alternatives or refurbished options can be discussed

- Warranty: 365 days replacement/repair coverage from delivery

Related/Supporting Components

- GE DS200TBTC – Thermocouple terminal board that mates with TCRA; provides field-wiring terminations and local CJC hardware.

- GE DS200TCQAG1A – Analog/quantizer or controller interface board in the Mark V core; receives processed data from input boards.

- GE DS200TBCAG1A – Termination board variant often used for field I/O aggregation; useful when expanding or reorganizing wiring.

If you’re unsure about the exact terminal board or revision pairing, share a photo of your existing rack slots and part labels—matching “G” group and revision letters typically avoids compatibility surprises.

Reviews

There are no reviews yet.