Description

GE DS2020FECNRP020A – Communication and Control Interface Module for GE Drive/Excitation Systems

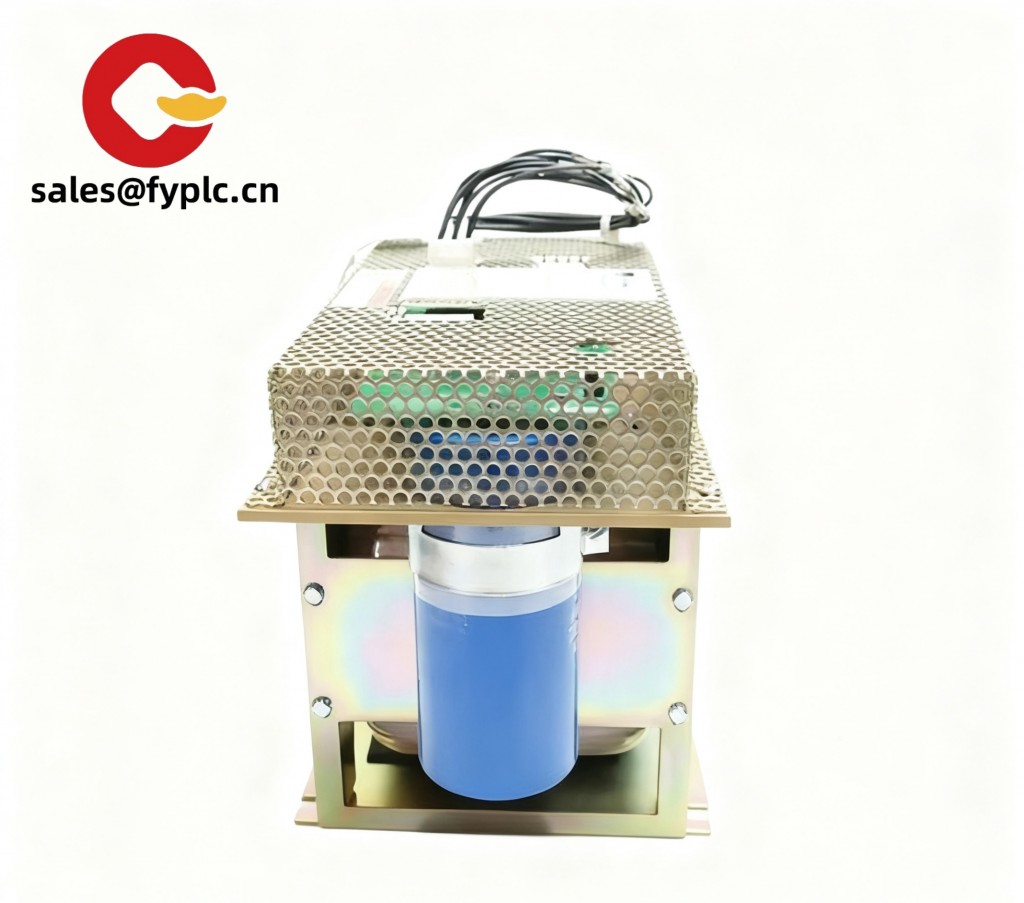

The GE DS2020FECNRP020A is a communication and control interface module designed for GE industrial control platforms, typically used in drive and excitation systems where reliable backplane communication and deterministic I/O handling are critical. From my experience, this module is selected to stabilize the link between the controller backplane and field-level signals or peer devices, helping reduce noise-related faults and intermittent comms in older cabinets.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week if in stock; no more than one month at the latest

- Payment terms: 50% advance payment; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Backplane communication stability – Engineered to maintain robust data exchange within the GE rack, which in many cases reduces nuisance trips caused by electrical noise.

- Signal conditioning and isolation – You might notice improved resilience when interfacing with mixed-voltage digital signals, especially in older drive and exciter cabinets.

- Field-proven GE design – The DS2020 family is commonly deployed in heavy industry; parts availability and documentation seem to be better than average for this class.

- Service-friendly diagnostics – Status indicators and test points typically help technicians troubleshoot without tearing down the cabinet.

- Drop-in replacement behavior – Designed to fit the existing slot and use backplane power; no external PSU or special wiring in most cases.

- Revision RP020A – This specific build level supports standard GE workflows; always match firmware/hardware revisions during changeout to avoid compatibility surprises.

Technical Specifications

| Brand / Model | GE DS2020FECNRP020A |

| HS Code | 853890 (Parts for switchgear/control panels) |

| Power Requirements | Backplane-supplied DC power; no external supply required (typical for DS2020 modules) |

| Operating Temperature | 0 to 55°C ambient, typical control cabinet conditions |

| Signal I/O Types | Backplane data/control bus; conditioned digital interfaces as implemented by system |

| Communication Interfaces | Rack backplane interface; service/serial access where provided by build |

| Installation Method | Plug-in rack module; mates to GE backplane connector; secured with front fasteners |

Application Fields

This module is commonly found in GE drive and excitation control cabinets in power generation, metals, oil & gas, and heavy process industries. Typical uses include:

- Excitation control systems where stable communications between controller, feedback, and protection circuits are required.

- Medium and large AC/DC drive systems coordinating speed, torque, and field regulation.

- Plant modernization projects extending the lifecycle of installed GE racks without a full platform migration.

Advantages & Value

- Reliability under electrical noise – Better stability in cabinets with high harmonics or switching loads, based on what we typically see in the field.

- Compatibility and continuity – Designed for GE DS2020 architecture, reducing engineering change time during replacements.

- Lifecycle cost control – A targeted board-level replacement is often more cost-effective than controller upgrades or rewiring.

- Support and documentation – Clear test/LED points make troubleshooting faster, which can cut downtime.

“We swapped the DS2020FECNRP020A during a planned outage and immediately cleared intermittent comms faults with the exciter. Zero nuisance trips since.” — Maintenance Supervisor, combined-cycle plant

Installation & Maintenance

- Environment: Install in a sealed control cabinet with adequate ventilation; keep ambient within typical 0–55°C and avoid moisture/condensation.

- Wiring & grounding: Verify cabinet grounding and shield terminations; route signal cabling away from high-power lines where practical.

- ESD handling: Use antistatic protection; de-energize the rack before insertion/removal.

- Slotting: Match slot location and revision RP020A to site documentation; check jumpers/straps if applicable.

- Maintenance: Inspect connectors quarterly; clean with dry, oil-free air; review event logs; apply firmware updates only when validated by your site standard.

- Spare strategy: Keep at least one tested spare on hand for critical-production lines, especially where lead time can stretch during peak seasons.

Quality & Certifications

- Manufactured to GE’s quality standards; production typically aligned with ISO 9001 quality systems.

- Meets industrial EMC/safety requirements commonly associated with CE-marked control components (application-dependent).

- RoHS status varies by build and date code; confirm at order for compliance documentation.

- Manufacturer’s warranty: 12 months from shipment (365 days).

Related/Supporting Components

In many cabinets, DS2020FECNRP020A operates alongside GE control and feedback boards in the same rack. Common companions include drive control, feedback, and power interface modules from the DS200/DS2020 family. Matching revisions and firmware baselines across these boards usually results in smoother commissioning.

How to Order

- Share the model: GE DS2020FECNRP020A and your required quantity.

- Provide cabinet/rack details and the current board revision or a photo of the product label for compatibility check.

- We confirm stock and lead time, issue a quotation and PI.

- Payment: 50% advance; balance before delivery.

- Shipment via FedEx / UPS / DHL, with packing suitable for ESD-sensitive electronics.

Reviews

There are no reviews yet.