Description

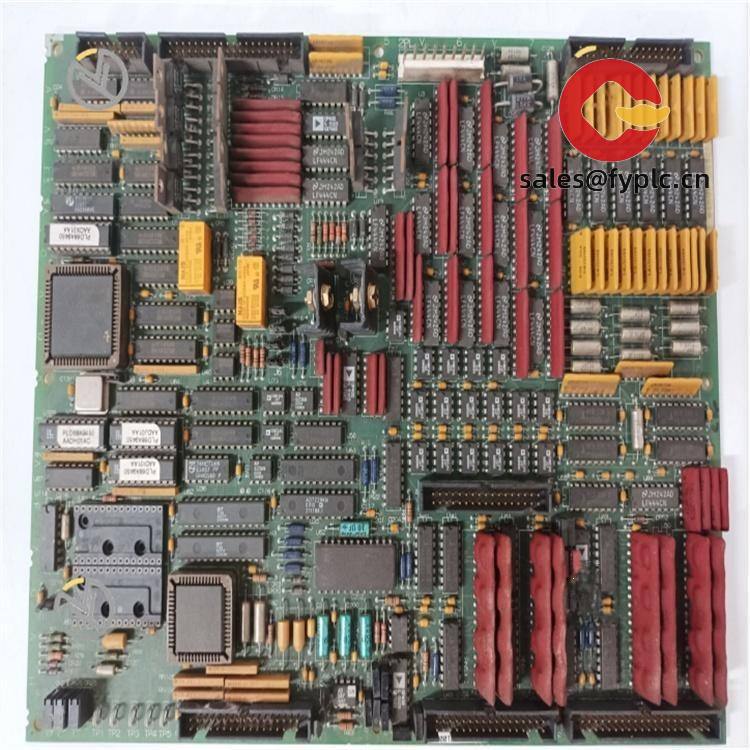

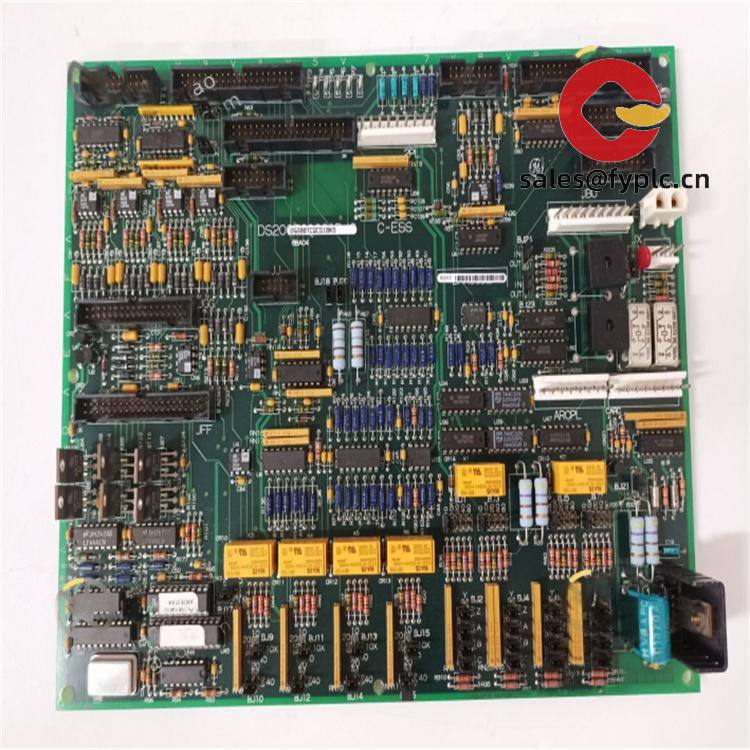

GE DS215DMCBG1AZZ03A – Processor and Communication Card for Mark V / GE Drive Systems

The DS215DMCBG1AZZ03A is a GE processor and communication card designed for Mark V Speedtronic panels and, in many cases, GE industrial drive platforms that share the DS200/DS215 architecture. It typically handles core CPU processing and plant network interface functions (such as Stage Link/ARCNET), acting as the bridge between the rack backplane and system communications. One thing I appreciate is how it keeps legacy systems stable without forcing a redesign—most sites just swap the board, verify firmware alignment, and they’re back online quickly.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days coverage.

- Lead time: 1 week if in stock; no more than one month at the latest.

- Payment: 50% advance payment; full payment prior to delivery.

- Express options: FedEx, UPS, DHL.

- Each unit is functionally checked before dispatch, with anti-static packaging and shock-safe packing.

Key Features

- Processor + Comms in one board – Coordinates control tasks while managing plant network traffic, reducing inter-board complexity.

- ARCNET/Stage Link connectivity (where configured) – Typically supports the Mark V coaxial network for reliable controller-to-panel communications.

- Backplane integration – Plug-in form factor with GE rack backplane connectivity; no field wiring lands on this board.

- Firmware carried on socketed devices – The “AZZ03A” suffix indicates a specific hardware/firmware build; EEPROM/PROM sets are usually socketed for serviceability.

- Form-Fit-Function replacement – Designed to drop into existing Mark V/GE drive cabinets with minimal configuration changes.

- Diagnostic-friendly – Onboard status LEDs and clear test points (typical for DS215 series) make commissioning and fault isolation faster.

Technical Specifications

| Brand / Model | GE (General Electric) / DS215DMCBG1AZZ03A |

| Product Type | Processor and communication card for Mark V / GE drive systems |

| HS Code | 8538.90 (Parts suitable for electrical control apparatus) |

| Power Requirements | Backplane supplied; typically +5 VDC and ±15 VDC, power draw < 10 W in most cases |

| Dimensions & Weight | Full-size DS215 PCB; approx. 330 × 280 mm; ~1.0 kg (typical) |

| Operating Temperature | 0 to 60 °C (panel conditioned environment) |

| Signal Input/Output Types | Digital backplane buses; ARCNET coax for plant network; service serial where fitted; no direct field I/O |

| Communication Interfaces | ARCNET/Stage Link (BNC coax, typical); RS-232/RS-485 service; GE backplane interfaces |

| Installation Method | Plug-in rack card; mates to backplane connectors; secure with captive screws; observe ESD precautions |

| Firmware/Revision | Suffix “AZZ03A” indicates specific hardware/firmware build; typically uses socketed PROM/EEPROM sets |

| Typical Compatibility | GE Mark V Speedtronic panels and select GE drive systems using DS200/DS215 backplanes (site verification recommended) |

Application Fields

From my experience, this board is most often specified in:

- Gas and steam turbine controls (Mark V Speedtronic cabinets)

- GE industrial drives and excitation systems that share the DS200/DS215 architecture

- Power generation, oil & gas, and metals plants where ARCNET-based panel networks are still standard

“We swapped in a DS215DMCBG1AZZ03A during a planned outage; align the PROM set, verify ARCNET link status, and it just works. Downtime was under two hours.” — Maintenance Supervisor, combined-cycle plant

Advantages & Value

- Reliability – GE DS215 boards are known for stable operation in harsh, high-uptime environments.

- Compatibility – Form-fit-function replacement reduces engineering changes; typically no cabinet modifications.

- Lifecycle savings – Keeping mature Mark V assets online is often far cheaper than accelerating a full DCS upgrade.

- Support – We can help match firmware revisions and check site compatibility before you place the order.

Installation & Maintenance

- Cabinet environment – Install in a clean, dry, ventilated panel. Keep ambient 0–60 °C with stable airflow; avoid dust loading.

- Power-down & ESD – De-energize the rack before handling. Use a grounded wrist strap and store the board in an ESD-safe bag when not installed.

- Mounting – Slide the board into the designated slot, mate fully with the backplane connectors, and tighten the captive screws evenly.

- ARCNET cabling – For coax networks, maintain 93 Ω cable and proper terminators. Check link LEDs and topology if communication alarms appear.

- Firmware alignment – Match PROM/EEPROM sets to your site configuration. Keep a verified backup of the previous firmware image.

- Routine care – Inspect connectors annually, clean dust with dry air (low pressure), and log any intermittent faults for trend analysis.

Quality & Certifications

- Manufactured to GE’s industrial standards; components are typically UL-recognized.

- CE conformity is usually determined at the panel/system level; board-level marking may vary by revision.

- RoHS status depends on build date; many earlier revisions are non-RoHS, which is expected for legacy spares.

- Warranty: 365 days (repair/replace as applicable).

If you share your existing part label or a photo of the PROM set, we can typically confirm drop-in compatibility for DS215DMCBG1AZZ03A before shipment. You might notice that this simple check avoids most commissioning surprises.

Reviews

There are no reviews yet.