Description

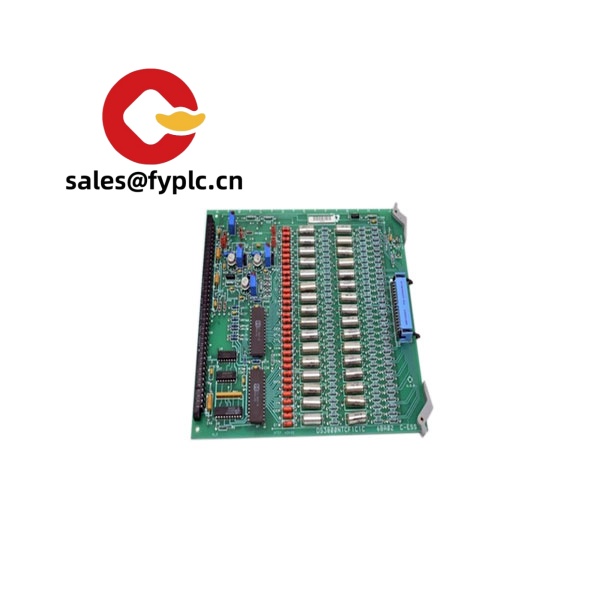

GE DS3800HMPK1J1J – Microprocessor Control Board for Speedtronic Mark IV Turbine Systems

The GE DS3800HMPK1J1J is a microprocessor control board used in Speedtronic Mark IV gas and steam turbine control systems. From my experience, this board functions as the main logic/processing module within a Mark IV card set, coordinating data across the backplane and supporting attached I/O boards. The “1J1J” suffix denotes a specific hardware/firmware revision pairing; it typically matters for like-for-like replacement and rack compatibility.

Plants usually keep one or two DS3800HMPK spares on the shelf because it’s a fast, drop-in swap during an outage. One thing I appreciate is how these boards, despite their legacy design, remain remarkably dependable when the firmware and rack wiring are kept consistent.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: In-stock items typically ship within 1 week; no more than one month at the latest

- Payment: 50% advance payment, full payment prior to delivery

- Express options: FedEx, UPS, DHL

- Pre-shipment testing: Functional check and visual inspection before dispatch

- Packing: ESD-safe, foam-protected packaging suitable for international transit

Key Features

- Mark IV-compatible microprocessor core: Designed for the GE Speedtronic Mark IV architecture to handle sequencing, logic, and interlocks.

- Backplane integration: Edge/backplane connectors provide deterministic communication with adjacent I/O and power boards.

- On-board diagnostics (typical): Status LEDs and test points aid quick bench checks and in-cabinet troubleshooting.

- Field-serviceable firmware: Socketed memory devices (EPROM/EEPROM on many revisions) support image verification and like-for-like replacement.

- Robust industrial build: Conformal coating is often present to improve resistance to humidity and airborne contaminants.

- Drop-in replacement: Form-fit-function replacement in existing Mark IV card racks, minimizing downtime.

Technical Specifications

| Brand / Model | GE DS3800HMPK1J1J |

| Product Type | Microprocessor Control Board for Speedtronic Mark IV |

| HS Code | 853890 (Parts for electrical control/switchgear) |

| Power Requirements | Supplied by Mark IV backplane; typically +5 VDC logic power (consumption varies by revision/configuration) |

| Operating Temperature | Typically 0 to +55 °C in control-room environments |

| Signal I/O Types | Digital backplane bus; local memory sockets; status LEDs (varies by suffix) |

| Communication Interfaces | Mark IV proprietary backplane interface (deterministic internal bus) |

| Installation Method | Plug-in card; mounts in Mark IV rack with card guides and backplane connector; faceplate fasteners for retention |

| System Compatibility | GE Speedtronic Mark IV turbine control systems (like-for-like replacement advised) |

Application Fields

The DS3800HMPK1J1J is used in turbine control packages where Mark IV is still the primary logic platform:

- Gas turbine start/stop sequencing and protection

- Steam turbine control in industrial cogeneration facilities

- Combined-cycle plants running legacy Mark IV panels

- Process plants and refineries relying on stable Mark IV interlocks

You might notice that many operators keep the Mark IV core intact due to proven reliability; swapping a single microprocessor board typically restores service faster than a full system upgrade.

Advantages & Value

- Reliability under real conditions: These boards have a long track record in utility and industrial environments when kept clean and correctly seated.

- True drop-in compatibility: Like-for-like replacement avoids rewiring or software migrations, saving outage time.

- Lifecycle cost control: Extends the service life of Mark IV without immediate capital expenditure on system replacement.

- Technical support: We can assist with revision checks, firmware image handling, and pre-shipment functional testing.

A maintenance lead from a combined-cycle plant told us the spare DS3800HMPK they kept “paid for itself” during a night shift trip event—board swap, verify LEDs, run-up test, and back on dispatch.

Installation & Maintenance

- Environment: Install in a clean, dry cabinet with adequate ventilation; keep temperature in typical control-room range.

- ESD precautions: Use grounding straps; handle by edges; avoid touching component pins and memory devices.

- Rack seating: Slide along card guides and fully mate the backplane connector; secure faceplate screws to prevent vibration issues.

- Wiring & connectors: Inspect ribbon and edge connectors for oxidation; reseat gently if alarms persist.

- Firmware alignment: Keep EPROM/EEPROM images consistent with site-approved versions; label and archive images for traceability.

- Routine care: Quarterly dust removal with dry, oil-free air; visual check for hot spots, lifted solder, or capacitor aging.

- Preventive strategy: Maintain at least one tested spare and rotate during planned outages to verify readiness.

Quality & Certifications

- Originally manufactured by GE for industrial duty; builds typically conform to OEM quality standards

- Units are supplied as new surplus or professionally refurbished, depending on availability

- CE / UL applicability varies by vintage and installation; ISO 9001 quality control applied at the distribution/testing stage

- RoHS may not apply due to legacy design; we can advise per lot

- Warranty: 365 days against functional defects under normal use

Reviews

There are no reviews yet.