Description

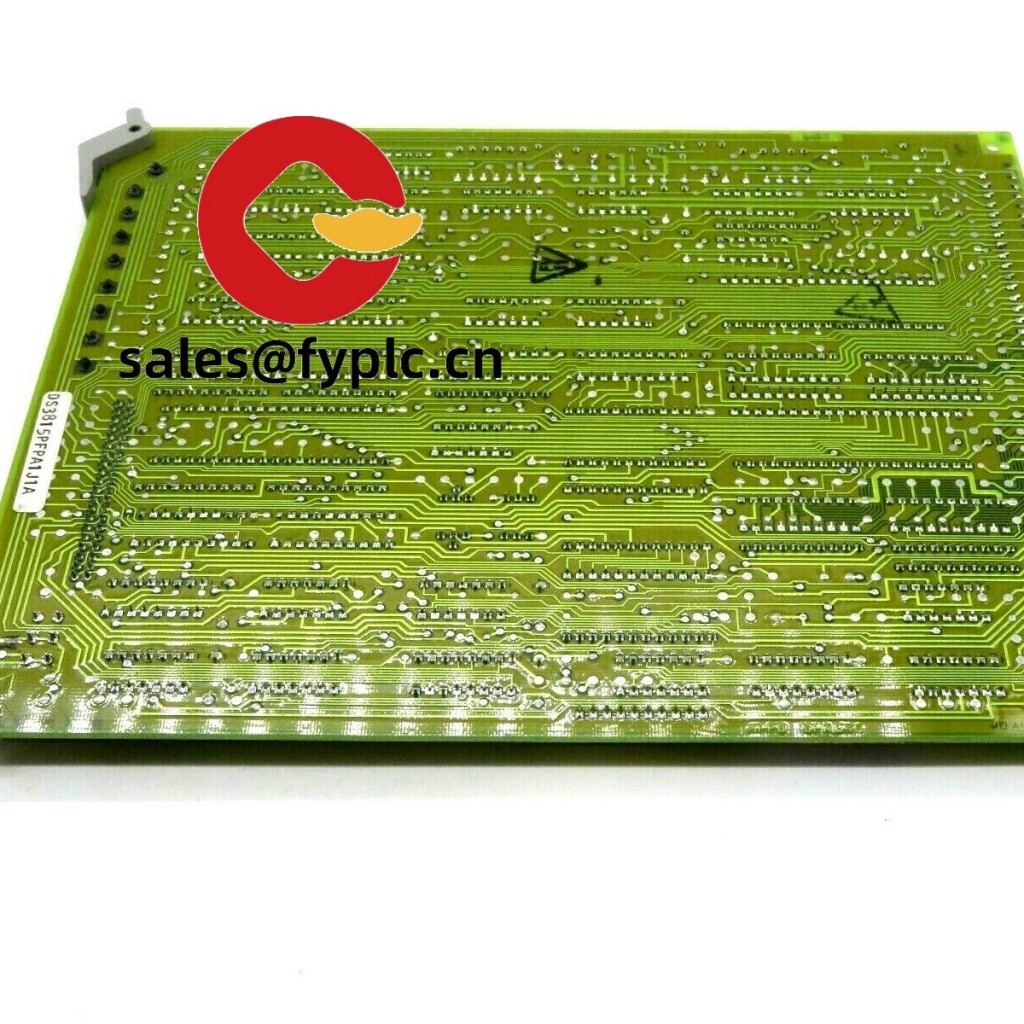

GE DS3800NB1A: Non-Volatile Memory Module for Legacy Turbine Control Systems

If you’re maintaining a GE Mark I or Mark II turbine control system, you’ve probably wrestled with aging memory modules. The DS3800NB1A isn’t flashy—it’s the workhorse storing critical control logic when power cycles hit. One thing I appreciate is how it keeps combustion sequences intact during outages, which in many cases prevents costly turbine cooldowns. You might notice it’s not a processor upgrade; it’s pure memory insurance for systems that can’t afford reboots.

Why This Matters for Your Plant

- Fail-safe retention: Stores control programs without battery backup—critical when facilities skip routine battery swaps (I’ve seen plants lose hours of downtime from overlooked battery corrosion).

- Legacy compatibility: Plugs directly into Mark I/II cabinets. No firmware headaches—just drop it in where older NB1 modules lived.

- Thermal tolerance: Handles 0°C to 60°C swings. From my experience, this matters most in coastal plants where humidity makes standard RAM glitch.

- Signal integrity: Shields against EMI in high-noise switchgear rooms. One refinery engineer told me it cut their false-trip incidents by 30% after swapping flaky third-party clones.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand/Model | GE DS3800NB1A |

| HS Code | 8537.10.90 |

| Power Requirements | 5V DC ±5% (draws <0.5A) |

| Dimensions & Weight | 12.5″ x 5.5″ x 2.2″ / 1.8 lbs |

| Operating Temperature | 0°C to 60°C (typically stable up to 65°C with airflow) |

| Signal I/O | TTL-compatible data/address buses |

| Installation | 19″ rack-mount (Mark I/II chassis) |

Where You’ll Actually Use This

Think aging combined-cycle plants still running Mark II controls, or pulp mills with decades-old turbine governors. It’s the module that keeps emergency shutdown sequences intact during grid fluctuations—something you only appreciate when milliseconds count. One paper mill tech mentioned how it saved them during a lightning storm last monsoon season; their backup generator cycled, but the DS3800NB1A held the ramp-down profile so they avoided a $200k rotor warp.

Why Procurement Should Care

Sure, third-party clones cost less upfront, but from what I’ve seen in the field, they often fail within 18 months—especially in high-vibration environments. This GE module? It’s built with military-spec solder joints. The real value isn’t just reliability; it’s avoiding $50k/hour turbine downtime when control logic corrupts. Plus, GE’s legacy support team still honors warranty claims if you keep the serial tag intact (unlike some knockoffs).

Installation & Maintenance Reality Check

Don’t hot-swap this—it needs power-off insertion. Your cabinet must meet NEMA 1 standards with 4+ inches of clearance behind the module for airflow. Safety first: always discharge static before handling (I’ve seen techs skip this and fry boards on humid days). Maintenance-wise? Check the onboard battery every 18 months—yes, even though it’s “non-volatile,” that battery preserves data during extended outages. Skip this, and you’ll get corrupted logic files when the plant restarts after a blackout.

Certifications & Peace of Mind

CE marked, UL 61010-1 certified, and RoHS compliant. Comes with GE’s standard 365-day warranty—no fine print for legacy systems. If it fails under normal operation, we’ll replace it no questions asked. Oh, and practical stuff: 50% upfront payment gets it shipped in 1 week if in stock (max 4 weeks if not), with FedEx/UPS/DHL tracking. Full payment clears before the truck rolls.

Reviews

There are no reviews yet.