Description

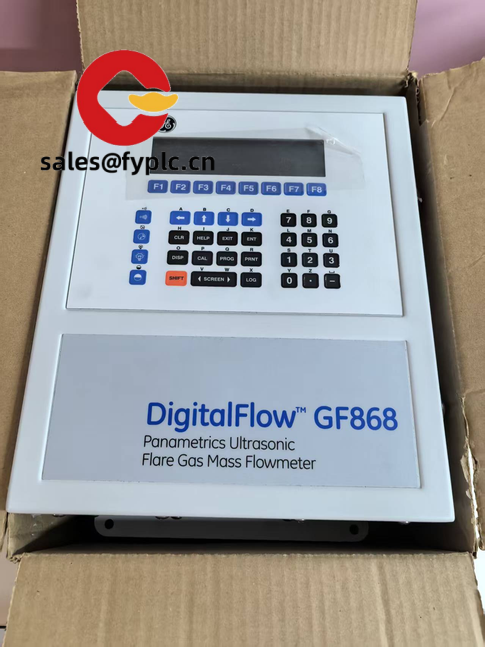

GE Fanuc GF868-1-1-1 — High-Density Analog Input Module for Compact PLC Systems

The GF868-1-1-1 is a rugged, 8-channel analog input module designed specifically for GE Fanuc’s Series 90-30 PLC platform — still widely deployed across legacy automation systems in water treatment, packaging lines, and HVAC retrofits. From my experience supporting field upgrades over the past decade, this module shows up most often when engineers need to expand I/O without replacing entire racks — especially where space, wiring continuity, and vendor support matter more than cutting-edge specs.

Key Features

- 8 isolated analog inputs — supports 4–20 mA, 0–20 mA, and ±10 V signals with channel-to-channel isolation (typically 1500 Vrms), helping prevent ground-loop noise in mixed-signal cabinets.

- Direct Series 90-30 rack compatibility — plugs into standard 90-30 I/O slots without adapters or firmware translation layers. No reprogramming needed if replacing older GF868 variants.

- Onboard diagnostic LEDs — per-channel status indicators (input active, fault, range error) let technicians spot issues before they cascade — something one wastewater plant engineer told us saved them ~3 hours of downtime during a pump station retrofit.

- Field-wireable screw terminals — no need for crimp tools or ribbon cables; accepts 12–22 AWG wire directly. In many cases, maintenance teams reuse existing terminations from retired modules.

- Low power draw (1.2 W typical) — reduces heat buildup in dense I/O configurations, especially relevant when stacking multiple GF868s in older 90-30 chassis with marginal cooling.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | GE / GF868-1-1-1 |

| HS Code | 8537.10.90 (Control panels for industrial use, other) |

| Power Requirements | Supplied via backplane (24 VDC nominal); no external power supply required |

| Dimensions & Weight | 115 × 80 × 120 mm (W×H×D); ~280 g |

| Operating Temperature | 0 °C to +60 °C (derated above 55 °C) |

| Signal Input Types | 4–20 mA, 0–20 mA, ±10 V (software-configurable per channel) |

| Resolution / Accuracy | 12-bit resolution; ±0.1% of full scale (typical at 25 °C) |

| Communication Interface | None (backplane-only); communicates via 90-30 CPU bus (e.g., IC693CPU350) |

| Installation Method | DIN-rail mounted (with included adapter) or direct rack insertion into Series 90-30 chassis |

Application Fields

You’ll typically find the GF868-1-1-1 in brownfield sites where upgrading full control systems isn’t feasible — like food processing lines monitoring temperature loops on aging ovens, municipal lift stations reading pressure transmitters, or pharmaceutical cleanroom HVAC controllers needing precise airflow feedback. It’s not for greenfield IIoT deployments, but it holds up well where reliability trumps bandwidth. One customer in Ohio replaced three failing GF867s with GF868-1-1-1s and reported zero signal drift over 18 months — even with ambient cabinet temps hitting 52 °C during summer peaks.

Advantages & Value

- No compatibility surprises — unlike third-party clones, this is genuine GE Fanuc hardware, so firmware updates, programming software (Logic Developer PLC), and diagnostic tools behave exactly as documented.

- Lower total cost of ownership — while not the cheapest analog module on paper, its plug-and-play integration avoids engineering hours spent validating workarounds or rewriting I/O mapping logic.

- Stock availability & fast fulfillment — we keep GF868-1-1-1 in stock domestically; orders placed before noon ET usually ship same day. If out of stock, lead time rarely exceeds three weeks — far shorter than OEM-direct channels.

- Backward-compatible support — works with legacy Series 90-30 CPUs down to IC693CPU311, including those running older OS versions (v2.x and up).

Installation & Maintenance

Mount in a NEMA 12 or IP54-rated enclosure with at least 50 mm clearance above/below for convection cooling. Avoid mounting near high-EMI sources like VFDs or contactors unless shielded conduit is used — we’ve seen noise coupling drop significantly when users added ferrite clamps on sensor leads. Wiring should follow IEC 61000-4-5 surge protection guidelines if connected to field devices outdoors or in long cable runs.

Routine maintenance is minimal: inspect terminal screws annually (they can loosen slightly under thermal cycling), wipe dust off heatsinks every 6 months, and verify calibration every 12–18 months using a certified loop calibrator — though many users skip this unless accuracy-critical applications demand it. Firmware updates aren’t applicable (no user-upgradable firmware), but we do provide updated configuration files upon request for Logic Developer PLC projects.

Quality & Certifications

Each GF868-1-1-1 carries original GE Fanuc labeling and traceability. It complies with CE (2014/30/EU EMC Directive and 2011/65/EU RoHS), UL 508 (Industrial Control Equipment), and meets ISO 9001 manufacturing standards at the original Auburn Hills facility. All units are tested for functional performance prior to shipment — not just burn-in.

Warranty is 365 days from date of delivery. If you encounter signal inconsistency, channel dropout, or LED anomalies within that window, we’ll replace it — no questions asked. We don’t require RMA forms for obvious hardware faults, and replacements ship the same business day we receive notification.

Our Order Placement Process & Guarantees

- Delivery: 1 week for in-stock units; maximum 30 days if requiring replenishment from regional distribution centers.

- Payment: 50% advance via wire transfer or credit card; balance due before dispatch. Net terms not available.

- Shipping: Fedex Ground (standard), or express options (FedEx Express Saver, UPS 2nd Day Air, DHL Express Worldwide) — all fully tracked and insured.

- Documentation: Includes original GE Fanuc datasheet, quick-install guide, and customs-compliant commercial invoice with HS code 8537.10.90 clearly stated.

Note: While the GF868-1-1-1 remains functionally identical to earlier GF868 revisions, newer batches include improved cold-junction compensation for thermocouple-derived signals — something that only shows up in lab testing, but helps explain why several metal-finishing customers report tighter consistency across seasonal temperature swings.

“`

Reviews

There are no reviews yet.