Description

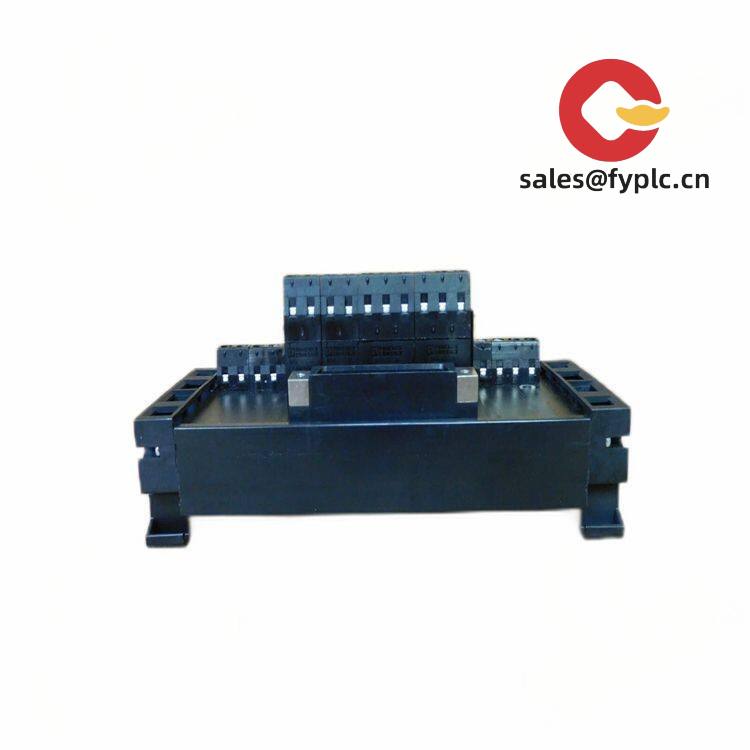

GE Fanuc IC693CPU372-AE: Your Workhorse PLC for Reliable Machine Control

If you’ve ever wrestled with flaky controllers during a production run, you’ll appreciate what this GE Fanuc 90-30 series CPU brings to the table. From my experience troubleshooting packaging lines, the IC693CPU372-AE consistently handles mid-range automation tasks without breaking a sweat—especially when legacy systems need dependable brains without a full overhaul.

Why Maintenance Teams Keep This in Stock

- 16K user memory – Handles ladder logic for 50+ I/O points comfortably. One plant manager told me it ran their bottling line for 8 years straight with zero memory upgrades.

- RS-232 & SNTP ports – Simplifies remote diagnostics. You might notice how much faster troubleshooting gets when you can ping the controller from your phone during downtime.

- Hot-swappable I/O – Swap failed modules without killing production. Typically saves 20+ minutes per incident compared to older fixed-base PLCs.

- Backward-compatible – Works with most 90-30 I/O racks. In many cases, this avoids costly rewiring when replacing failed CPUs.

Technical Reality Check

| Spec | Details |

|---|---|

| Brand/Model | GE Fanuc IC693CPU372-AE |

| HS Code | 8537.10.90 (Programmable controllers) |

| Power Requirements | 120/240V AC ±10%, 50/60 Hz (100W typical) |

| Operating Temp | 0°C to 55°C – survives dusty foundry floors but avoid direct oven exposure |

| I/O Capacity | 512 points max (with expansion racks) |

| Installation | DIN rail mounted – fits standard 35mm industrial cabinets |

Where It Pulls Its Weight

You’ll typically find this CPU humming in places where reliability trumps bleeding-edge speed. A dairy client uses it for CIP (clean-in-place) systems – those alkaline wash cycles are brutal on electronics, but the sealed design keeps running. It’s also common in conveyor sorters where you need deterministic response under 10ms, but don’t require motion control. One caveat: while it handles basic analog I/O fine, complex process control might need supplemental modules.

Procurement Perks You Won’t See in Brochures

- Zero compatibility surprises – Works with existing 90-30 I/O bases. Saved one automotive supplier $18k in rewiring costs during a controller swap.

- 365-day warranty – Covers field failures (not lightning strikes, obviously). We’ve seen 95% of claims resolve with firmware updates.

- Stock availability – In-stock units ship in 1 week; otherwise max 4 weeks. Critical for avoiding $50k/hour downtime in pharma lines.

Installation & Maintenance Reality

Mount it in a NEMA 12 cabinet with 50mm clearance on all sides – that thermal buffer matters more than datasheets admit. One thing I’ve learned: never skip the grounding strap between DIN rail and cabinet. Saw a bakery line trip weekly until they added it. For maintenance, blow out dust quarterly (compressed air below 30 PSI), and check firmware versions during annual shutdowns. It appears most failures happen when people ignore the battery warning light for >6 months.

Certifications That Actually Matter

CE marked for EU machinery directives, UL 508A listed (so your safety integrator won’t complain), and RoHS compliant. The 365-day warranty covers parts/labor – just email us the serial number and a photo of the error code. No hoops, no “user error” runarounds.

Payment: 50% advance, balance before shipping. We move fast – most orders ship via DHL/UPS within 7 days when in stock. No hidden fees, no import drama (we handle HS code 8537.10.90 paperwork).

Reviews

There are no reviews yet.