Description

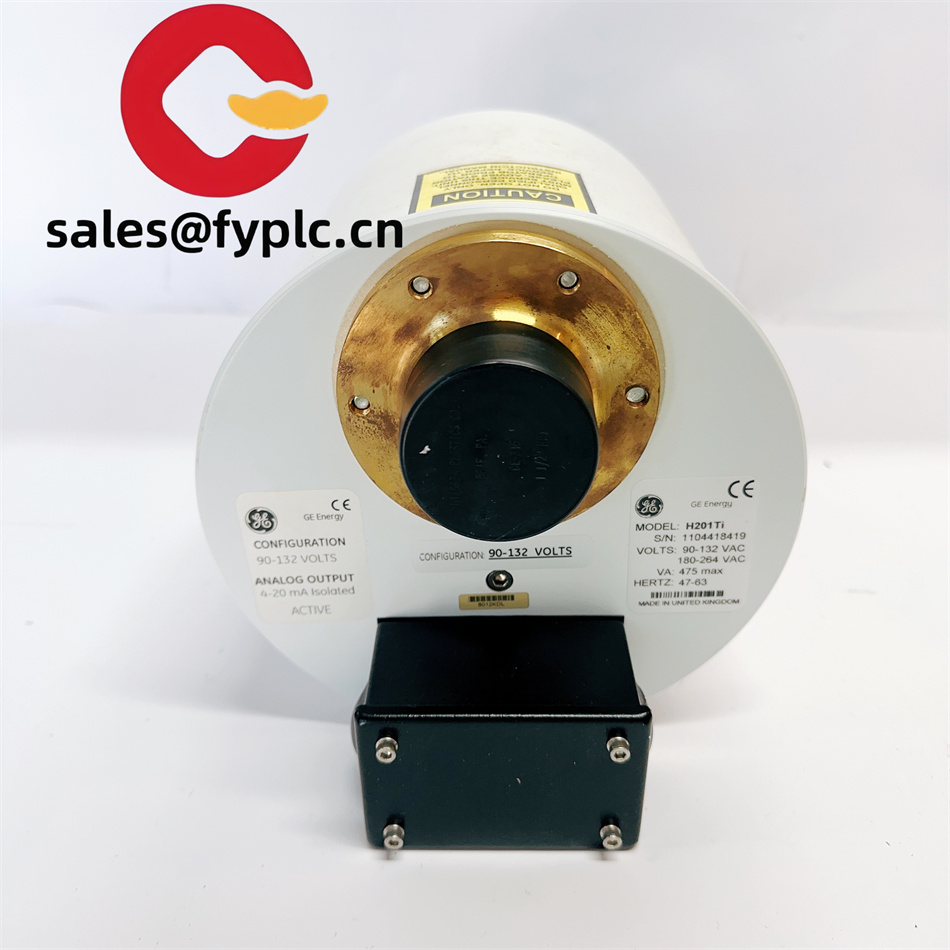

GE H201Ti Single Gas Detector Transformer

|

Label

|

Specification

|

|

Model

|

H201Ti

|

|

Brand

|

GE

|

|

Type

|

Online early – warning transmitter for DGA monitoring

|

|

Power Supply

|

110 – 240V AC

|

|

Communication

|

Modbus RTU, RS485

|

|

Measurement Range

|

0 – 1000A

|

|

Accuracy

|

± 0.5%

|

|

Sensor Options

|

– “Hydran composite gas” sensor: 100% responsive to hydrogen, also sensitive to carbon monoxide, acetylene, and ethylene. – “Hydrogen – only” sensor: Only focuses on hydrogen generation

|

|

Output

|

– Digital output via Modbus RTU over isolated RS – 485. – Analogue output options: 0 – 1mA non – isolated (standard), 4 – 20mA isolated (optional)

|

|

Dimensions and Weight

|

Compact design for easy installation. Weight is approximately 5.6 kilograms (12 pounds)

|

|

Environmental Compatibility

|

Operating temperature range suitable for industrial environments. Can withstand certain levels of vibration and temperature fluctuations

|

|

Alarm Features

|

– Two configurable alarm levels (e.g., “Alert” and “Alarm”) based on gas ppm levels or gas rate – of – change (ROC) over an hour or a day. – Automatic self – test every 15 days, triggering a service alarm in case of detected faults such as power loss, oil valve closure, or sensor/battery replacement needs

|

|

Interface

|

– Backlit LCD for local gas information display. – Keyboard for device operation like stopping the device and acknowledging alarms. – Local USB port for data transfer (replacing the less – used RS – 232 port in most modern setups). Compatible with GE’s Perception™ software for data download and trend analysis

|

- Continuous and Precise Monitoring: The H201Ti offers real – time, continuous monitoring of key fault gases. This continuous data stream provides operators with an in – depth and up – to – date understanding of the transformer’s condition. The ability to measure gas concentrations accurately, with an accuracy of ± 0.5%, ensures that even minor changes in gas levels, which could be precursors to major faults, are not overlooked.

- Versatile Sensor Options: With the availability of two types of sensors – the “Hydran composite gas” sensor and the “hydrogen – only” sensor – the H201Ti can be tailored to different monitoring requirements. The composite gas sensor, being sensitive to multiple gases associated with different types of faults (hydrogen for general faults, carbon monoxide for paper overheating, acetylene for arcing, and ethylene for oil overheating), provides a comprehensive view of the transformer’s health. The hydrogen – only sensor, on the other hand, offers a more focused and cost – effective solution for applications where hydrogen monitoring is the primary concern.

- Remote Monitoring Capability: By supporting communication protocols like Modbus RTU over RS485, the H201Ti enables remote transmission of gas ppm values and gas change – rate values. This is a significant advantage as it allows operators to monitor transformer conditions from a remote location, eliminating the need for frequent on – site visits. Remote monitoring not only saves time and resources but also enables quick response times in case of detected anomalies.

- Reliable Fourth – Generation Design: The H201Ti features a fourth – generation design that has been continuously improved. With over 25,000 units sold globally, its reliability is proven. The design improvements include enhanced sensor durability, a new electronic board, and a power supply that complies with RoHS standards. These enhancements not only improve the device’s reliability but also its functionality, ensuring long – term, trouble – free operation.

- User – Friendly Interface: The device is equipped with a backlit LCD for clear display of gas information, even in low – light conditions. The keyboard simplifies device operation, allowing for easy control such as stopping the device and acknowledging alarms. Compatibility with GE’s Perception™ software further enhances the user experience by enabling data download, trend analysis, and more advanced data management features.

- Power Distribution Systems: In power grids, the H201Ti plays a vital role in ensuring the reliable operation of transformers. By providing early warnings of potential faults, it helps power utilities prevent unplanned outages, which can have significant economic and social impacts. For example, it can detect the early signs of insulation breakdown in a transformer, allowing maintenance teams to schedule timely repairs and replacements, thus minimizing the risk of sudden failures.

- Industrial Automation: In industrial plants, transformers are used to power various machinery and equipment. The H201Ti helps industrial operators monitor the health of these transformers, reducing the risk of production disruptions due to transformer failures. In a manufacturing facility that relies heavily on continuous power supply for its production lines, the H201Ti can ensure that any potential transformer issues are detected early, preventing costly downtime and production losses.

FOXBORO FCP270 P0917YZ

Yokogawa CP451-50 ABB 3HAB9271-1/01B

ABB 3HAB8859-1/03A

GE CT11T7F10PN1ABB DSQC509

Mark VIe IS200EPSMG1AEDABB BC25

IS200SPROH1AAB MRP663860ABB 07BR61R1 GJV3074376R1

ABB 6231BP10910

Reviews

There are no reviews yet.