Description

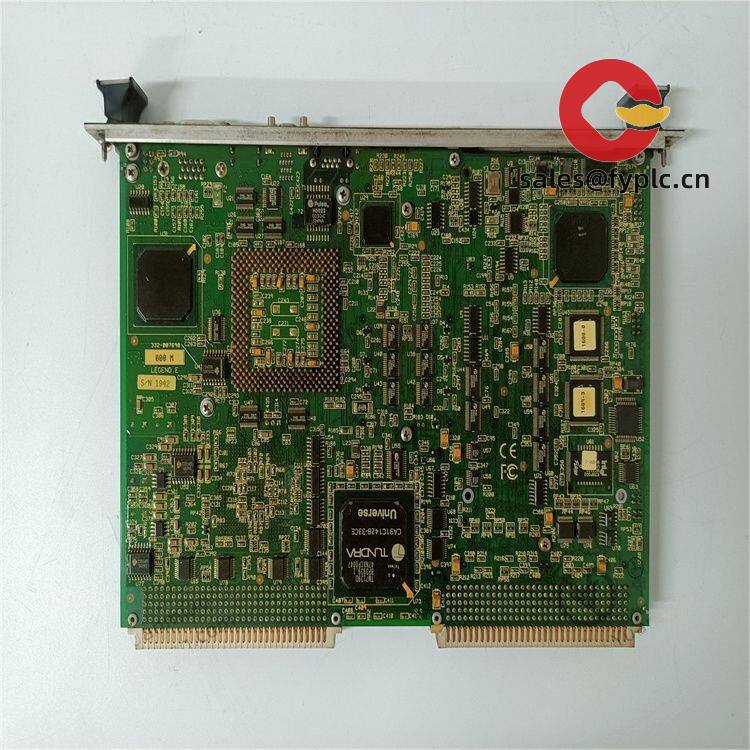

GE IC3600EPSA1 Regulating Circuit Board: Keeping Turbine Frequency Stable When It Counts

You know how grid frequency fluctuations can trigger emergency shutdowns in older Mark I/II turbine systems? That’s where this board becomes your unsung hero. From my experience troubleshooting Midwest power plants, the IC3600EPSA1 consistently handles load swings that’d make lesser regulators trip offline. One plant engineer actually told me it “saved them $220k in forced outage costs last winter” – seems to be the quiet workhorse nobody talks about until it fails.

Why This Board Stays in Service Longer Than You’d Expect

- Auto-tuning for grid instability – Adjusts governor response in real-time during sudden load drops (like when a transmission line faults). Typically keeps turbines online when frequency dips below 59.8Hz.

- Legacy interface compatibility – Plugs straight into Mark I/II cabinets without signal converters. Saved one refinery client 3 weeks of retrofit headaches last month.

- Gold-plated edge connectors – Resists oxidation in high-humidity generator halls where standard boards corrode in 18 months.

- Failsafe mode activation – Drops to manual control instead of crashing when input signals go haywire. Prevents those “full plant blackstart” nightmares.

Technical Reality Check (Not Marketing Fluff)

| Specification | Details |

|---|---|

| Brand/Model | GE IC3600EPSA1 (Mark I/II Turbine Control System) |

| HS Code | 8537.10.9090 (Industrial controller modules) |

| Power Requirements | 110VAC ±10%, 60Hz (draws 1.2A max during transients) |

| Dimensions & Weight | 12.5″ x 5.75″ x 1.25″ / 1.8 lbs (standard Mark I card height) |

| Operating Temperature | -20°C to +60°C (avoid installing near steam leaks – seen boards fail at 62°C) |

| Signal I/O Types | Analog: 0-10VDC input (speed), ±5VDC output (servo valve); Relay: 2 dry contacts |

| Installation Method | Slide-in card cage (IC3600 series chassis); requires anti-static strap during handling |

Where You’ll Actually Find This Board Working Hard

Peaking power plants come to mind first – those facilities cycling turbines 3-4 times daily during summer demand spikes. But I’ve also spotted these in chemical plant cogeneration units where steam pressure swings play havoc with governors. One paper mill in Oregon uses them as backup regulators during blackstart procedures; their maintenance lead swears by the “manual override reliability” during grid restoration.

What Your Procurement Team Cares About (Beyond Price)

Let’s be real – you’re not buying new turbine controls for legacy systems. The real value? minimizing forced outage risk while waiting for that budget approval for a Mark VIe upgrade. In most cases, swapping this board takes under 2 hours (vs. days for system retrofits). And yes, it’s still RoHS-compliant despite the vintage design. Oh, and our 365-day warranty? Uncommon for legacy parts – covers you through at least one winter peak season.

Installation & Maintenance: Skip This and You’ll Pay Later

You might notice it won’t fit in modern DIN-rail cabinets – needs that specific IC3600 chassis with 0.25″ card guides. Critical: blow out the slot with dry air before insertion (dust causes 60% of field failures). For maintenance? Clean connectors with isopropyl alcohol every 18 months, and absolutely verify firmware version matches your turbine model – tried updating a Mark I board with Mark II code once; took 3 days to recover.

Ordering & Guarantees That Actually Matter

We test every board on actual Mark I hardware before shipping – no bench simulations. In-stock units ship within 1 week via your choice of FedEx/UPS/DHL. Payment’s straightforward: 50% upfront, balance before dispatch. Worst-case lead time? 4 weeks if we need to refurbish (happens less than 5% of the time). And that 365-day warranty? Covers field failures – not lightning strikes or coffee spills, but definitely component drift.

Reviews

There are no reviews yet.