Description

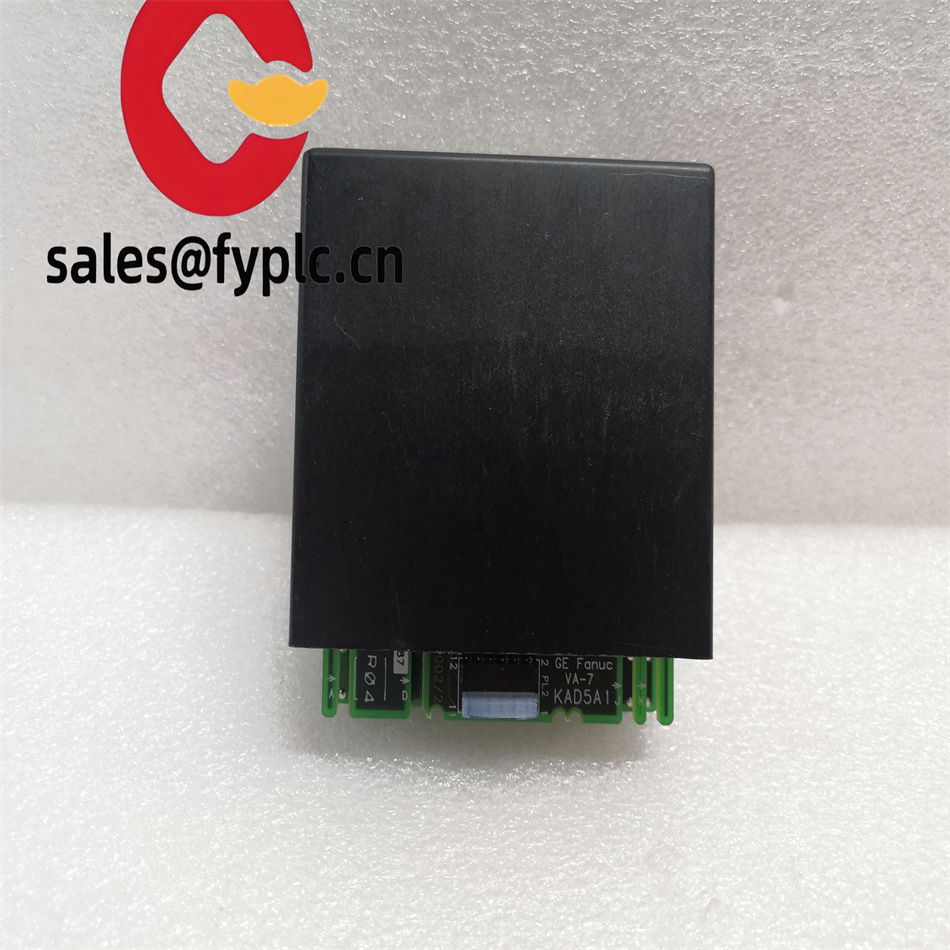

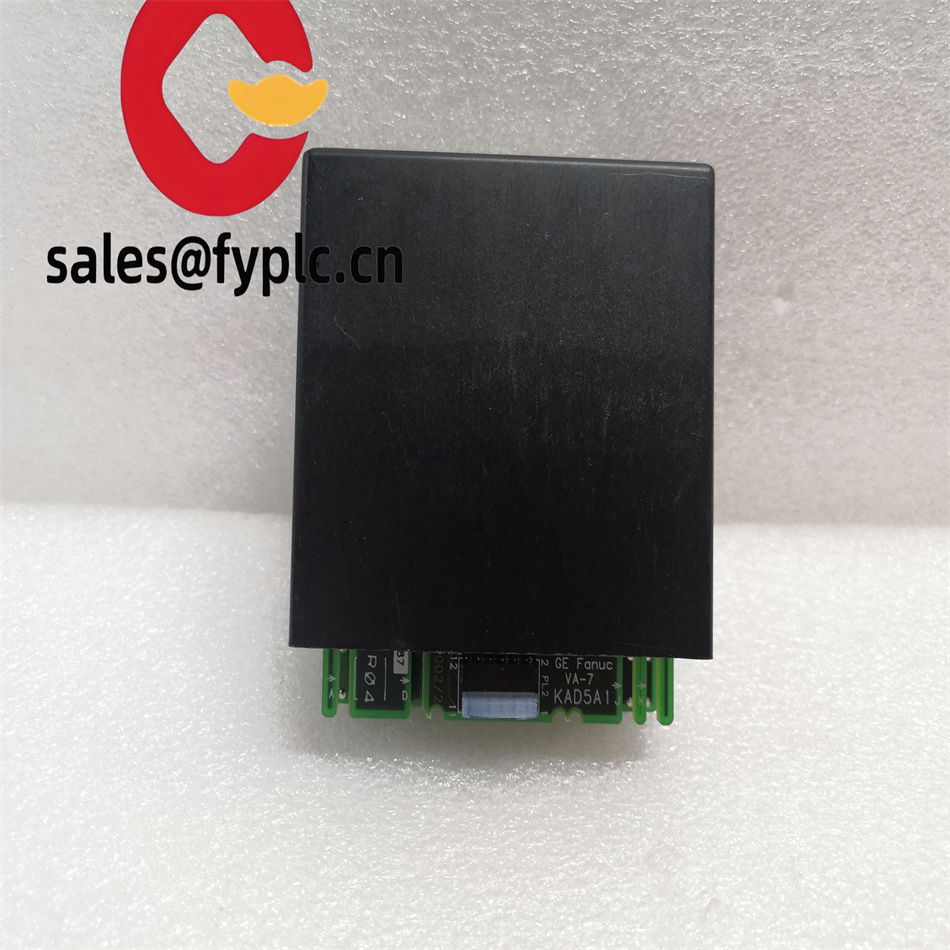

GE IC670ALG310-JA Wireless Information Ethernet Control Module

In the intricate realm of industrial automation and control systems, the GE IC670ALG310-JA stands out as a high – performance analog input module, engineered to meet the most demanding requirements of modern industrial applications. This advanced module serves as a crucial link between field sensors and control systems, enabling accurate data acquisition and seamless integration into various industrial setups.

The GE IC670ALG310-JA is specifically designed to handle a wide range of analog input signals with exceptional precision. It plays a vital role in industrial control systems, such as Distributed Control Systems (DCS) and Programmable Logic Controllers (PLC) – based systems. By accurately converting analog signals from sensors, such as temperature, pressure, and flow rate sensors, into digital data that can be processed by the control system, it ensures that operators have real – time, reliable information about the process variables. This accurate data acquisition is essential for maintaining process stability, optimizing production efficiency, and ensuring the safety and reliability of industrial operations across diverse sectors, including manufacturing, power generation, and chemical processing.

The GE IC670ALG310-JA offers a plethora of functional strengths and design advantages that make it a top choice for industrial applications. Its high – resolution design ensures that even the slightest changes in analog input signals can be accurately detected and converted, providing operators with detailed and precise process information. The module’s excellent accuracy, with a low margin of error, guarantees that the data it provides is reliable for critical decision – making in industrial processes.

In terms of build quality, the GE IC670ALG310-JA is constructed to withstand the harsh conditions of industrial environments. It is resistant to electrical noise, vibrations, and temperature fluctuations, ensuring stable operation over an extended period. The module’s compatibility with a wide range of existing industrial control systems and equipment simplifies integration, reducing the complexity and cost of system upgrades. Additionally, its user – friendly design makes installation and maintenance straightforward, minimizing downtime and maximizing the overall efficiency of the industrial automation system.

The GE IC670ALG310-JA finds extensive use in numerous industrial scenarios, delivering significant value across different industries. In manufacturing plants, it is used to monitor and control various production processes. For example, in a chemical manufacturing plant, it can accurately measure the flow rate and temperature of chemical fluids, enabling precise control of the reaction processes and ensuring product quality. In power generation facilities, the module plays a crucial role in monitoring parameters such as steam pressure, turbine temperature, and electrical current, helping to optimize power generation and ensure the stable operation of the power grid.

There are several related models to the GE IC670ALG310-JA that offer different features to meet specific industrial needs. The GE IC670ALG222 might have a different number of input channels or a higher sampling rate, making it suitable for applications that require more extensive data acquisition. The GE IC670ALG441 could offer enhanced accuracy or a wider input voltage range, catering to applications with more stringent requirements. These related models provide users with the flexibility to choose the most appropriate module based on their specific industrial automation requirements.

When it comes to setting up the GE IC670ALG310-JA, proper installation is key to its optimal performance. During installation, ensure that all electrical connections are secure and follow the recommended wiring diagrams to avoid any electrical interference or signal distortion. Pay attention to grounding requirements to safeguard against electrical surges and ensure accurate data acquisition. For long – term operation, regular maintenance is recommended. Periodically check the module for any signs of wear and tear, loose connections, or abnormal heat generation. Update the firmware as needed to take advantage of the latest features and improvements, and ensure that the module continues to operate at its best.

For more information, please click below to learn more:

Reviews

There are no reviews yet.