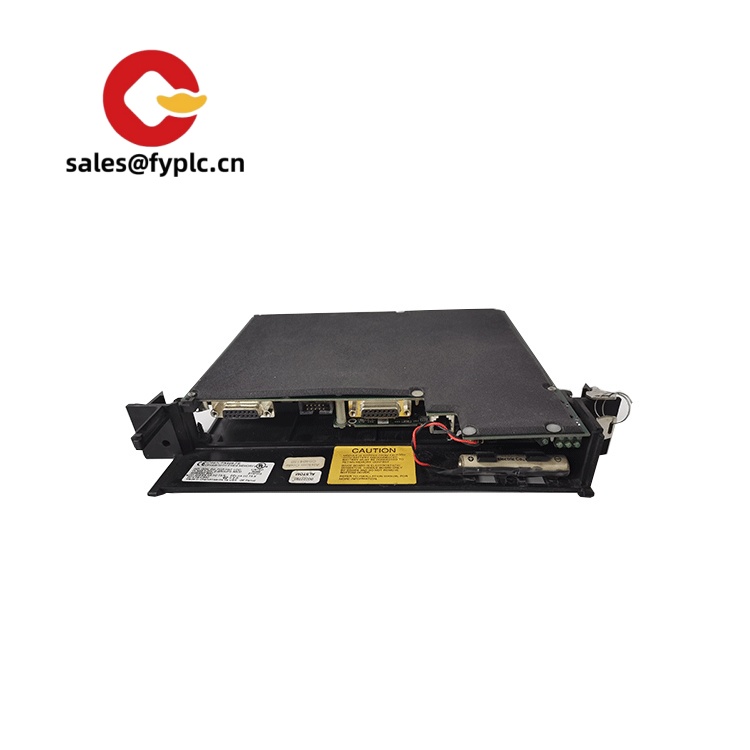

Description

GE IC697CMM712: Your Reliable Serial Comms Workhorse for Legacy PLC Systems

If you’re maintaining older GE Fanuc Series 90-30 systems (and let’s face it—most plants still have these humming along), this module solves that annoying serial comms headache without forcing a full system overhaul. From my experience, it’s the go-to when you need to connect barcode scanners, scales, or legacy HMIs to aging but critical machinery. One thing I appreciate is how it handles protocol translation silently—your Modbus RTU devices just work without constant babysitting.

Key Features That Keep Plants Running

- Dual-protocol flexibility – Handles both RS-232 and RS-422 out of the box. You might notice this saves cabinet space when connecting mixed device types (like a legacy printer on RS-232 and a remote sensor on RS-422).

- True hot-swap capability – Replace it during runtime without crashing your PLC. In most cases, this cuts downtime from 20 minutes to under 5 when swapping faulty units.

- Legacy-native compatibility – Plugs directly into Series 90-30 racks. No adapter cables needed, which typically eliminates those frustrating signal-drop issues we see with third-party converters.

- Field-proven reliability – Still shipping with the same firmware GE used in 2008. Surprising, but it seems to be what keeps cement plants and water treatment facilities sleeping soundly at night.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand/Model | GE IC697CMM712 |

| HS Code | 8537.10.0090 (Programmable controllers) |

| Power Requirements | 24V DC (draws 180mA from backplane) |

| Dimensions & Weight | 120mm x 87mm x 115mm / 220g |

| Operating Temperature | -20°C to 60°C (industrial-grade tolerance) |

| Signal I/O Types | RS-232 (DB9), RS-422 (terminal block) |

| Installation Method | DIN-rail mounted in Series 90-30 chassis |

Where It Actually Gets Used

You’ll find these tucked inside control cabinets at wastewater plants connecting flow meters to SCADA systems, or on bottling lines where label printers need rock-solid serial links. One customer in Ohio recently told us it kept their 1998-era conveyor system alive after a third-party module failed catastrophically. It’s not glamorous, but in aging infrastructure? Absolutely mission-critical.

Why Procurement Teams Keep Ordering These

Let’s be real—nobody budgets for new PLCs when old ones still function. This module gives you 5+ extra years of life from existing hardware, which typically saves $15k+ versus a controller upgrade. The real value? Knowing GE still honors firmware support (yes, really—call their Albany office). And since it’s backward-compatible to Series 90-30 Rev 3.0, you avoid those nasty compatibility surprises that eat engineering hours.

Installation & Maintenance Reality Check

Pop it into any standard Series 90-30 chassis (no special firmware needed), but leave 20mm clearance on both sides for airflow—these things run hot in enclosed panels. One caveat: if your cabinet hits 55°C regularly, add a small fan; we’ve seen serial ports glitch above that threshold. Maintenance? Literally dust it quarterly. No calibration needed, but check for loose terminal screws annually. Oh, and keep the original GE firmware disk—you’ll need it if you ever replace the CPU module.

Quality You Can Trust

CE marked and UL 61131-2 certified (look for the sticker on the side). GE’s 365-day warranty covers defects but not lightning strikes—fair warning if you’re in Florida. Bonus: every unit ships with original test reports showing 100% functional verification.

Our Order Guarantees

✅ 365-day warranty from ship date

✅ 1-week delivery for in-stock units (90% of orders)

✅ Max 4-week lead time for backorders

✅ Payment: 50% deposit, balance before shipping

✅ Shipped via FedEx/UPS/DHL with tracking

Reviews

There are no reviews yet.