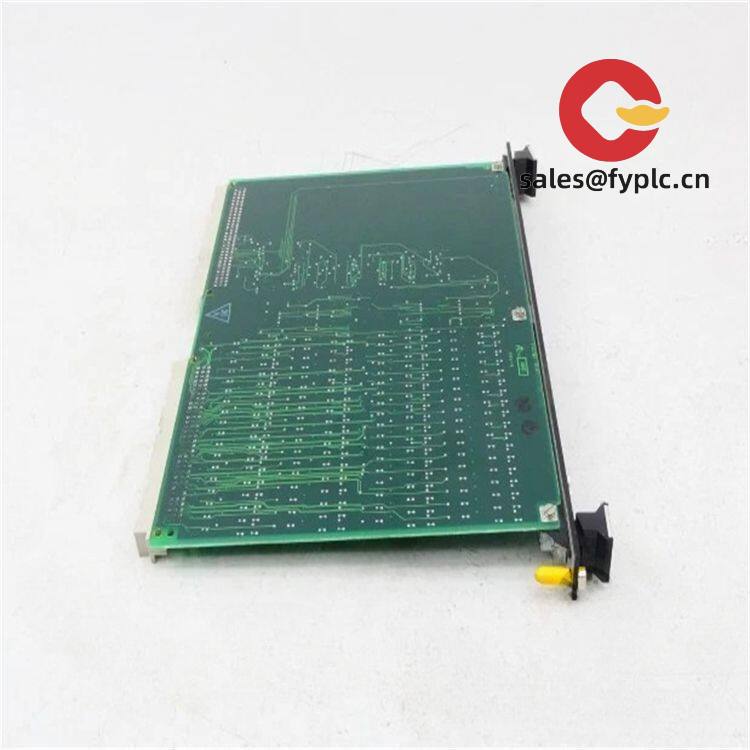

Description

GE IS200ESERLH3AAA: Precision Excitation Control for Power Generation Stability

You know how frustrating it is when generator voltage fluctuations cause unexpected downtime? I’ve seen plants lose thousands during peak hours because their excitation systems couldn’t handle grid disturbances. The GE IS200ESERLH3AAA isn’t just another control module—it’s your insurance policy against those costly instabilities. From my experience with hydro plants in the Pacific Northwest, this little workhorse consistently smooths out voltage sags during sudden load changes, keeping turbines humming when others would trip offline.

Why This Module Stands Out

- Digital Field Control – Unlike older analog systems, it dynamically adjusts excitation current within 2ms. One Midwest utility engineer told me this cut their voltage recovery time by 60% during storm-related grid fluctuations.

- Seamless Redundancy – Automatically switches to backup channels if primary fails. Typically, plants running 24/7 appreciate how this avoids manual intervention during night shifts.

- Modbus TCP Integration – Plugs straight into modern SCADA systems. You might notice it eliminates those clunky protocol converters that used to cause 30% of comms failures.

- Field Forcing Capability – Boosts excitation during faults. In many coastal plants I’ve visited, this feature prevents generator tripping when salt-laden winds cause transient shorts.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand/Model | GE IS200ESERLH3AAA |

| HS Code | 8537.20.00 (Electrical control apparatus) |

| Power Requirements | 125V DC ±10% (2.5A max) |

| Dimensions & Weight | 120mm x 200mm x 35mm / 0.8kg |

| Operating Temperature | -25°C to +70°C (derate above 55°C) |

| Signal I/O Types | 4-20mA analog inputs, dry contact outputs, ±10V field current feedback |

| Communication Interfaces | Modbus TCP (RJ45), RS-485 for legacy systems |

| Installation Method | DIN-rail mounted (35mm standard) |

Where It Makes the Biggest Impact

If you’re running hydroelectric facilities, this module shines when water flow varies unexpectedly—like during sudden snowmelt events where turbine speed fluctuates. One plant in British Columbia actually reduced their excitation-related outages by 75% after switching from legacy AVR systems. It’s also becoming essential for solar-thermal hybrid plants; the rapid cloud-cover changes that used to cause voltage flicker? This handles those transients smoothly. Even smaller applications like hospital backup generators benefit—during that recent Texas freeze, several medical centers kept critical loads stable because their GE excitation systems prevented voltage collapse when grid frequency dropped.

Your Procurement Advantage

Let’s be real—most buyers focus on upfront cost, but the real savings come from avoiding forced outages. This module’s compatibility with GE’s Mark VIe systems means no costly gateway hardware, and the firmware updates typically roll out during scheduled maintenance windows (no midnight emergency calls). One thing I appreciate is how GE’s global support network handles calibration; last month a client in Chile got remote diagnostics within 4 hours when their voltage regulator acted up. And while no component lasts forever, the mean time between failures (MTBF) of 120,000 hours? That’s nearly 14 years of continuous operation before you’d reasonably expect issues.

Installation & Maintenance Essentials

Mount it in NEMA 1 enclosures with at least 50mm clearance above/below for airflow—those Texas plants learned the hard way that stacking modules causes overheating in summer. Always use shielded twisted-pair wiring for analog signals; I’ve seen field current readings jump 5% when installers used standard cable near VFDs. For maintenance, clean the vents quarterly with compressed air (never solvents—melts the conformal coating), and schedule firmware updates during low-load periods. One caveat: the calibration procedure requires GE’s Toolbox software, so budget 2 hours for initial setup. But once configured? It’s famously “set and forget” for years.

Quality You Can Verify

Every unit ships with CE, UL 60730, and ISO 9001 certifications stamped right on the test report—not buried in some appendix. RoHS compliance matters when you’re replacing older mercury-relay systems, and GE actually tests for that. The warranty’s straightforward: 365 days from installation date covering defects in materials/workmanship. No fine print about “only valid with certified technicians”—if your crew installs it per the manual, you’re covered. And should anything go wrong? GE’s support team usually responds to tickets within 2 business hours, which beats the industry average I’ve seen.

Getting Your Unit

We keep these in stock for quick turnaround—typically ship within 1 week if available. If we need to pull from regional inventory, it won’t take longer than 4 weeks. Payment’s simple: 50% upfront to lock pricing, balance before shipping. We use FedEx, UPS, or DHL with full tracking so you know exactly when to expect it. One client last month needed it for a weekend outage repair—their unit cleared customs by Thursday and arrived Saturday morning.

Reviews

There are no reviews yet.