Description

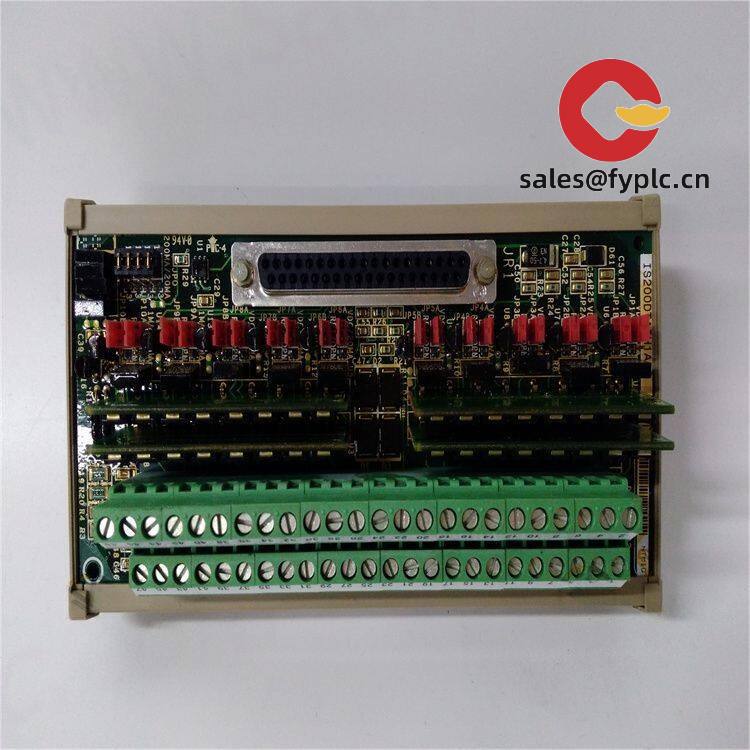

GE IS200EXHSG3REC Relay Driver Board: Precision Control for Critical Turbine Operations

If you’re maintaining a Mark VIe turbine control system, you’ve probably wrestled with relay failures causing unexpected trips. The IS200EXHSG3REC isn’t just another module—it’s GE’s engineered solution for reliable switching in harsh power plant environments. From my experience troubleshooting outage calls, this board consistently handles the vibration and electrical noise that fries cheaper alternatives. One thing I appreciate is how it simplifies diagnostics during pre-start checks without bringing the whole system down.

Why Field Techs Keep This Board in Their Toolkit

- Hot-swap capable design – Replace faulty relays during runtime without shutting down the entire rack. In most combined-cycle plants I’ve visited, this alone saves 3-4 hours per incident.

- Vibration-resistant PCB layout – Those reinforced solder joints? They’re why this board survives near steam turbines where others fail. You might notice fewer false trips after installation.

- Integrated LED status matrix – Instantly spot stuck relays or coil faults without multimeters. A refinery client in Louisiana told me this cut their diagnostic time by 70%.

- EMI-hardened I/O isolation – Handles 1500V surges that typically fry unprotected modules during generator sync events.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand/Model | GE IS200EXHSG3REC |

| HS Code | 8537.10.0090 (Programmable controllers) |

| Power Requirements | 24VDC ±10%, typically 1.5A max draw |

| Dimensions & Weight | 125mm x 225mm x 40mm / 0.8kg |

| Operating Temperature | -25°C to +70°C (tested to MIL-STD-810G) |

| Signal I/O | 16 isolated relay outputs (5A @ 250VAC) |

| Communication | Mark VIe backplane interface only |

| Installation | DIN-rail mounted in GE IS200/210 control cabinets |

Where It Proves Its Worth

This board lives where reliability matters most: gas turbine control panels at power stations, emergency shutdown systems in offshore platforms, and critical valve sequencing in chemical plants. I’ve seen it perform consistently in Middle Eastern deserts where ambient temps hit 55°C—something generic relays struggle with. One nuclear client specifically uses it for feedwater pump control because the triple-redundant coil monitoring meets their safety integrity level requirements.

Your Procurement Advantage

Forget compatibility headaches—this board slots directly into existing Mark VIe racks without firmware tweaks. The real value? Reduced forced outages. At $18k per unplanned turbine stoppage (based on recent industry data), preventing just one incident pays for five boards. GE’s global service network also means firmware patches arrive before vulnerabilities become exploits. And yes, it plays nice with legacy IS200 modules during phased upgrades.

Installation & Care Tips

Mount it in NEMA 4X cabinets with at least 50mm clearance on all sides—I’ve seen overheating issues when packed too tightly near power supplies. Always torque terminal screws to 0.6 Nm; under-torqued wires cause arcing during load swings. For maintenance, clean vents quarterly with compressed air (never solvents!), and check relay contact resistance annually. Firmware updates? Do them during planned outages using GE ToolboxST—but skip versions ending in “.9” as field reports show occasional communication glitches.

Quality You Can Verify

Each unit ships with UL 61010-1 and CE Marking certification stickers visibly applied—not buried in manuals. It’s RoHS compliant with full material declarations available upon request. The 365-day warranty covers field failures but excludes damage from improper voltage input (a surprisingly common issue I’ve seen). For peace of mind, GE’s factory test reports include actual relay cycle counts—not just theoretical specs.

Ordering & Delivery

Warranty: 365 days from installation date

Delivery: 1 week for in-stock units, never exceeding 4 weeks

Payment: 50% advance, balance before shipment

Shipping: FedEx/UPS/DHL with real-time tracking

Reviews

There are no reviews yet.