Description

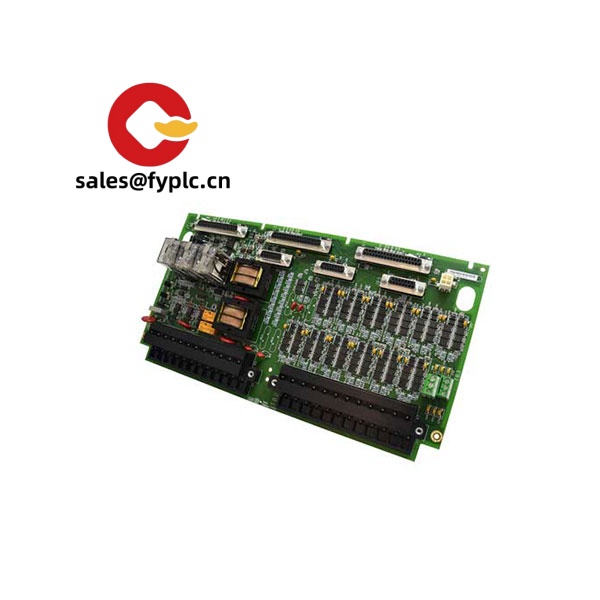

GE IS200RAPAG1B – Relay Auxiliary Power Assembly for Mark VI Control Racks

The GE IS200RAPAG1B is a Relay Auxiliary Power Assembly board used in GE Speedtronic Mark VI control systems. From my experience, it’s the quiet workhorse that conditions and distributes the DC wetting power your relay outputs rely on. You might notice that it helps stabilize contact performance, reduces nuisance trips, and adds protection against surges and transients in turbine and balance-of-plant panels. The G1B revision typically remains compatible within the RAPA/RAPA-G1 family, making drop-in maintenance simpler in many cases.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Conditioned wetting power for relay outputs: Provides stable DC to improve contact reliability and reduce chatter, typically feeding TRLY-type terminal boards.

- Surge and transient protection: Protective components help absorb spikes on control power, which in many cases extends relay and contact life.

- Board-level fusing and monitoring: Localized protection assists fault isolation; maintenance teams can identify issues without tracing the whole rack.

- Mark VI rack integration: Designed to plug into the Mark VI backplane for clean power distribution and status sense—no extra communications wiring.

- Service-friendly layout: The component placement seems to prioritize quick inspection and replacement, keeping outage windows short.

- G1B revision stability: Typically backward-compatible with earlier RAPA variants, which helps when stocking spares across multiple units.

A maintenance lead once told me, “Swapping the RAPAG board cleared intermittent output drops we’d been chasing for weeks.” That kind of feedback lines up with what we usually see when wetting power has been marginal for a while.

Technical Specifications

| Brand / Model | GE / IS200RAPAG1B |

| Product Family | Speedtronic Mark VI Control System (Relay Auxiliary Power Assembly) |

| HS Code | 8538.90 (Parts for electrical control/switchgear) |

| Power Requirements | Typically sourced from the control DC bus (commonly 125 VDC in Mark VI panels; verify site drawings) |

| Operating Temperature | 0 to 60°C (typical control cabinet environment) |

| Signal I/O Types | DC control power input; conditioned/fused wetting power to relay output circuits; backplane status sense |

| Communication Interfaces | None (board-level; interfaces through the Mark VI backplane) |

| Installation Method | Plug-in PCB assembly for Mark VI rack; mates with backplane and associated terminal board/cabling |

| Dimensions & Weight | Standard IS200 board form-factor; lightweight module (board-level assembly) |

Related or Supporting Products

- IS200TRLYH1B – Relay Output Terminal Board; pairs with wetting power from RAPAG to drive field relays.

- IS200TBCIH1C – Contact Input Terminal Board; often in the same cabinet, handling dry/wet contact inputs.

- IS200STCIH2A – Simple Contact Input module; alternative input density depending on channel count.

- IS200RAPAG1A / IS200RAPAG1C – Neighboring revisions; used as form-fit-function replacements in many cases.

- IS200DSPXH1D – Mark VI control processor board; not a power board but commonly co-located in the same rack.

If you’re standardizing spares, I typically group RAPAG with TRLY and the specific contact I/O boards for a complete relay output chain.

Installation & Maintenance

- Cabinet & environment: Install in a clean, ventilated Mark VI rack within a sealed control cabinet. Maintain ambient 0–60°C and avoid condensation.

- Wiring & power: Use the designated control DC bus; verify polarity and fusing. Ensure relay wetting power routing matches the TRLY/terminal board wiring diagram.

- ESD handling: Wear grounding straps; handle the board by edges only. Seat firmly into the backplane to avoid intermittent contacts.

- Safety: Isolate control power and tag-out before insertion/removal. Confirm discharge of stored energy where applicable.

- Routine checks: Inspect fuses, connectors, and any protective components during outages. Light dust cleaning with dry air; no solvents.

- Functional verification: After replacement, validate wetting voltage and perform relay output prove-out tests. Firmware isn’t typically applicable to this board, so focus on electrical checks.

Quality & Certifications

- Certifications: CE and UL compliance are typical for Mark VI components; RoHS status may vary by revision. Manufacturer quality systems align with ISO 9001.

- Warranty: 365-day coverage from shipment. Items are tested and carefully packed for transit.

If you share your panel voltage and relay board part numbers, I can double-check compatibility and make sure the IS200RAPAG1B fits your exact Mark VI configuration without surprises.

Reviews

There are no reviews yet.