Description

GE IS200TRLYH1BGF – High-Integrity, Fail-Safe Relay Module for Mark VIe Turbine Control Systems

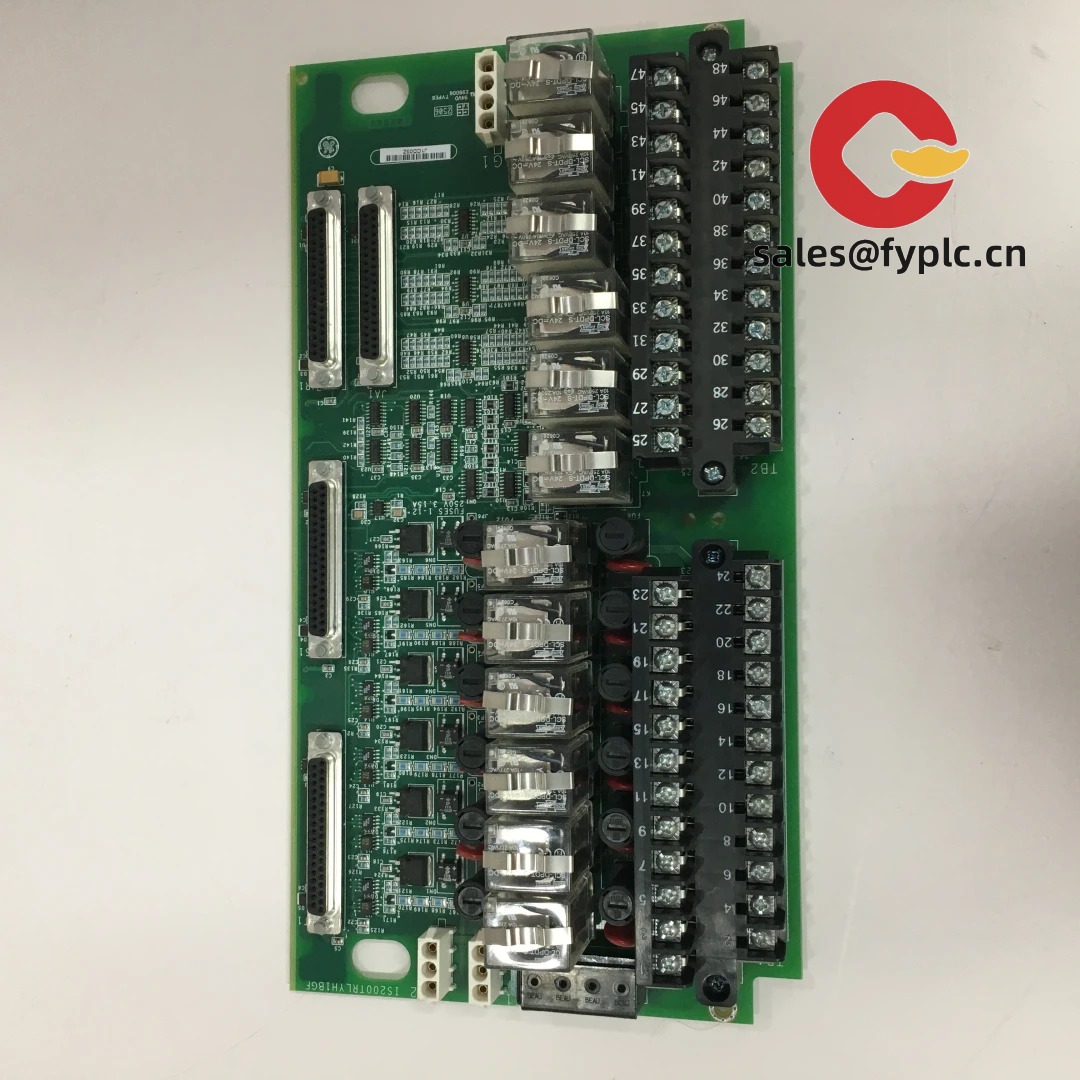

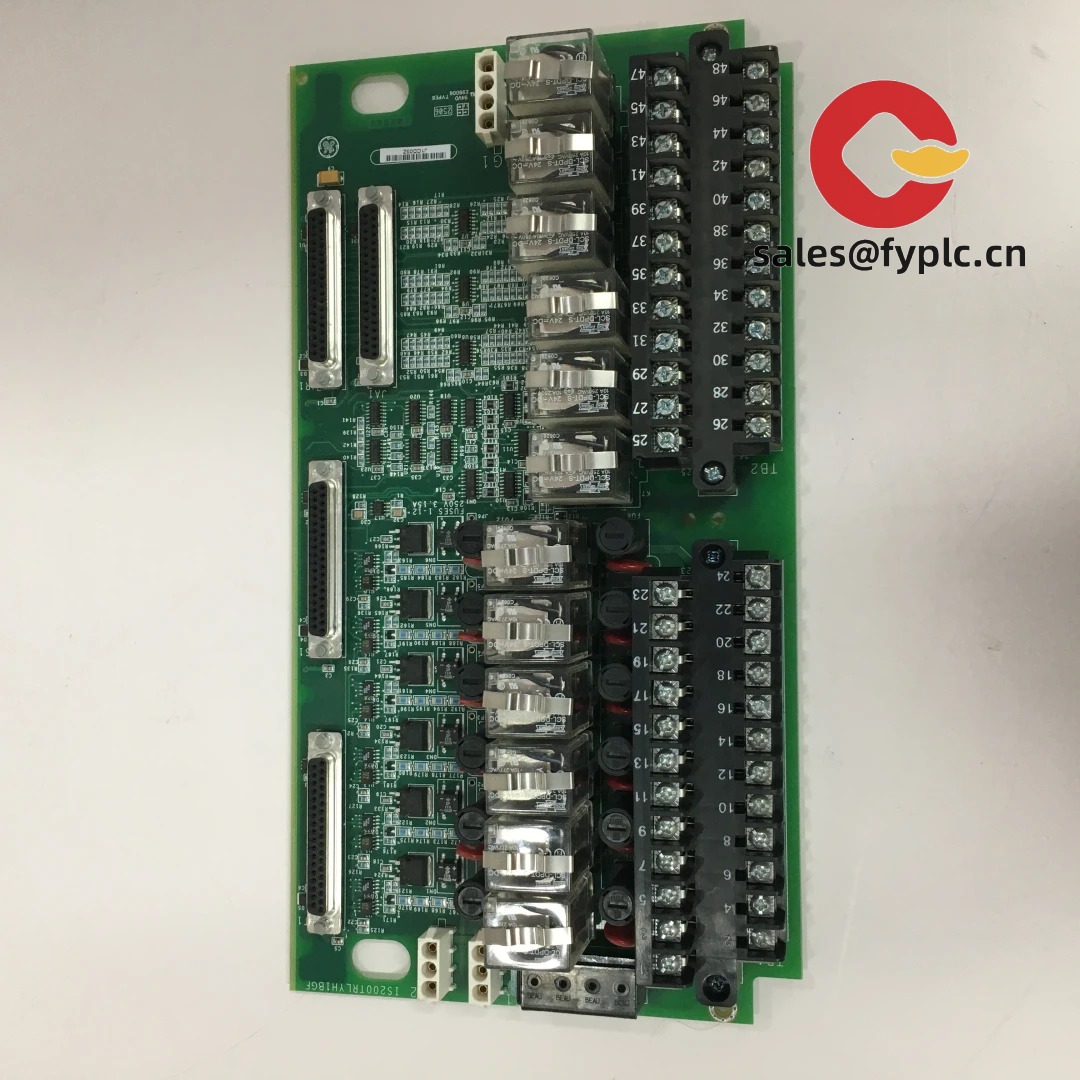

The IS200TRLYH1BGF is a purpose-built, high-integrity relay output module designed exclusively for GE’s Mark VIe turbine control platform. It’s not a generic I/O card—it’s the final hardware link between safety-critical logic and physical shutdown devices: emergency trip solenoids, fuel valve cut-offs, lube oil dump valves, and fire suppression triggers. The “H1” in the model denotes its SIL 2/3-capable architecture, while “BGF” signals factory-configured fail-safe operation with forced de-energization on fault or loss of control power. In real-world use, this module sits inside the turbine protection cabinet—often bolted directly next to the overspeed detection system—and must respond within milliseconds when commanded. From my experience supporting power plant retrofits, engineers consistently cite its deterministic timing and certified failure modes as key reasons they specify it over third-party alternatives.

Key Features

- Fail-Safe, De-Energize-to-Trip Logic (BGF) — Outputs are *normally energized* during healthy operation and automatically de-energize on processor fault, communication loss, or power failure. This means if the control system goes dark—or even loses a single Ethernet packet—the relay drops out and initiates shutdown. One nuclear plant operator told us this behavior was non-negotiable during their NRC-mandated safety review.

- High-Integrity Dual-Channel Architecture (H1) — Uses dual independent microcontrollers with cross-monitoring, watchdog timers, and hardware-based voting. Unlike software-only redundancy, this includes dedicated analog comparators and discrete safety logic that operates even if the main CPU locks up.

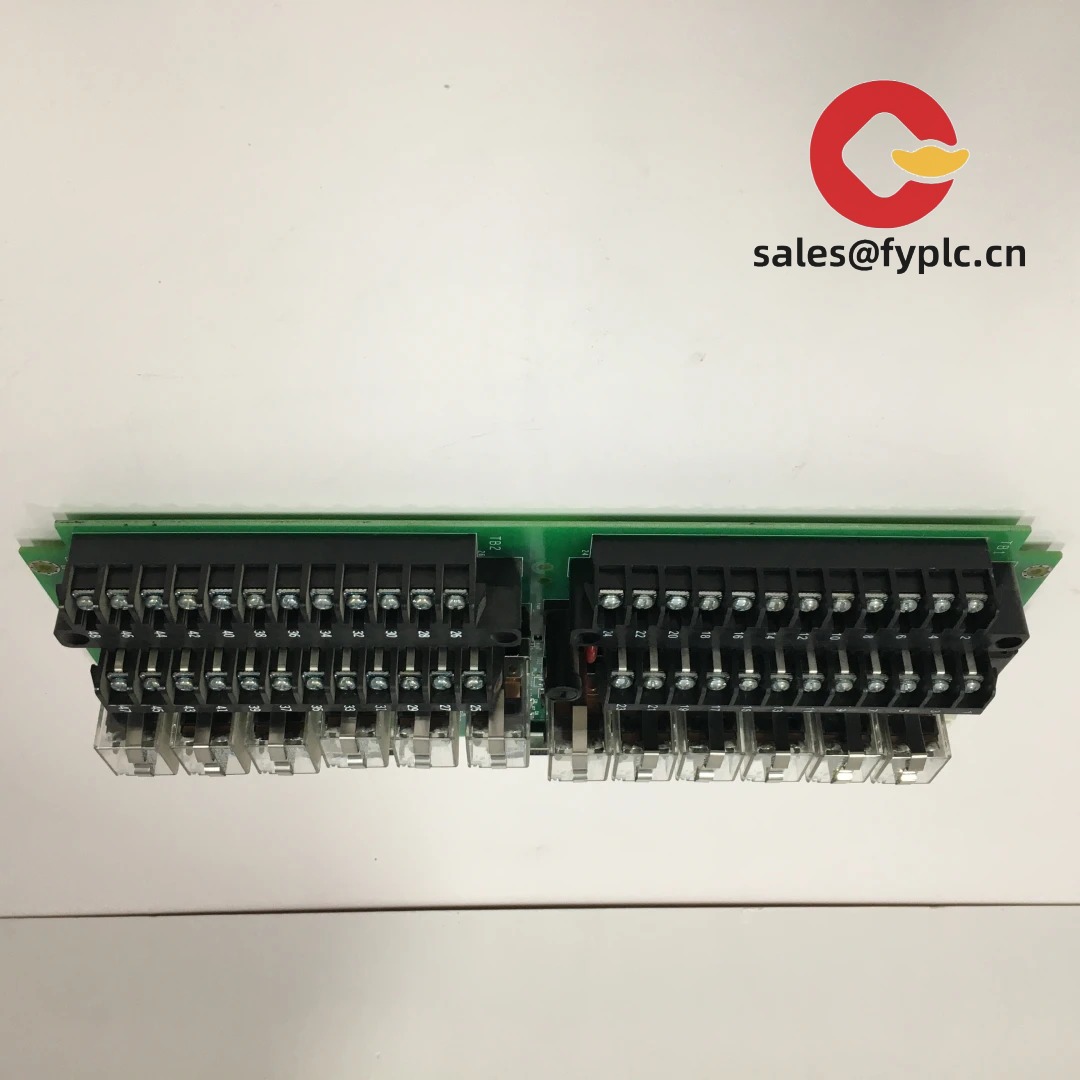

- 16 Form-C Safety Relays, 5 A @ 250 VAC — Each channel is independently fused and optically isolated. You’ll notice the terminals are spaced wider than standard relays—this isn’t just for clearance; it’s to meet creepage/clearance requirements for SIL 3-rated circuits per IEC 61800-5-2.

- Native Integration with Mark VIe — Communicates over GE’s HSB (High-Speed Bus), not Modbus or Ethernet. That means sub-10 ms update times and guaranteed deterministic execution—no protocol translation delays, no polling jitter. Configuration happens entirely within ToolboxST, using pre-certified function blocks.

- Field-Replaceable Without System Downtime — Hot-swappable design allows replacement while the Mark VIe remains online. A technician in a combined-cycle plant once swapped one during a scheduled turbine inspection—no isolation required, no logic reload needed.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | GE IS200TRLYH1BGF |

| HS Code | 8536.49.0090 (Relay modules for industrial control systems) |

| Power Requirements | 24 VDC nominal (18–32 VDC); typical consumption 14 W (max 18 W) |

| Dimensions & Weight | 240 × 125 × 225 mm (W×H×D); ~2.6 kg |

| Operating Temperature | −20 °C to +70 °C (operational), −40 °C to +85 °C (storage) |

| Signal Outputs | 16 isolated Form-C relays; contact rating: 5 A @ 250 VAC / 30 VDC (resistive); 2 A @ 250 VAC (inductive) |

| Diagnostic Capabilities | Per-channel open-circuit, short-circuit, and welded-contact detection; built-in self-test on power-up and periodic runtime checks |

| Communication Interface | HSB (High-Speed Bus) only—requires connection to Mark VIe controller via backplane or HSB cable |

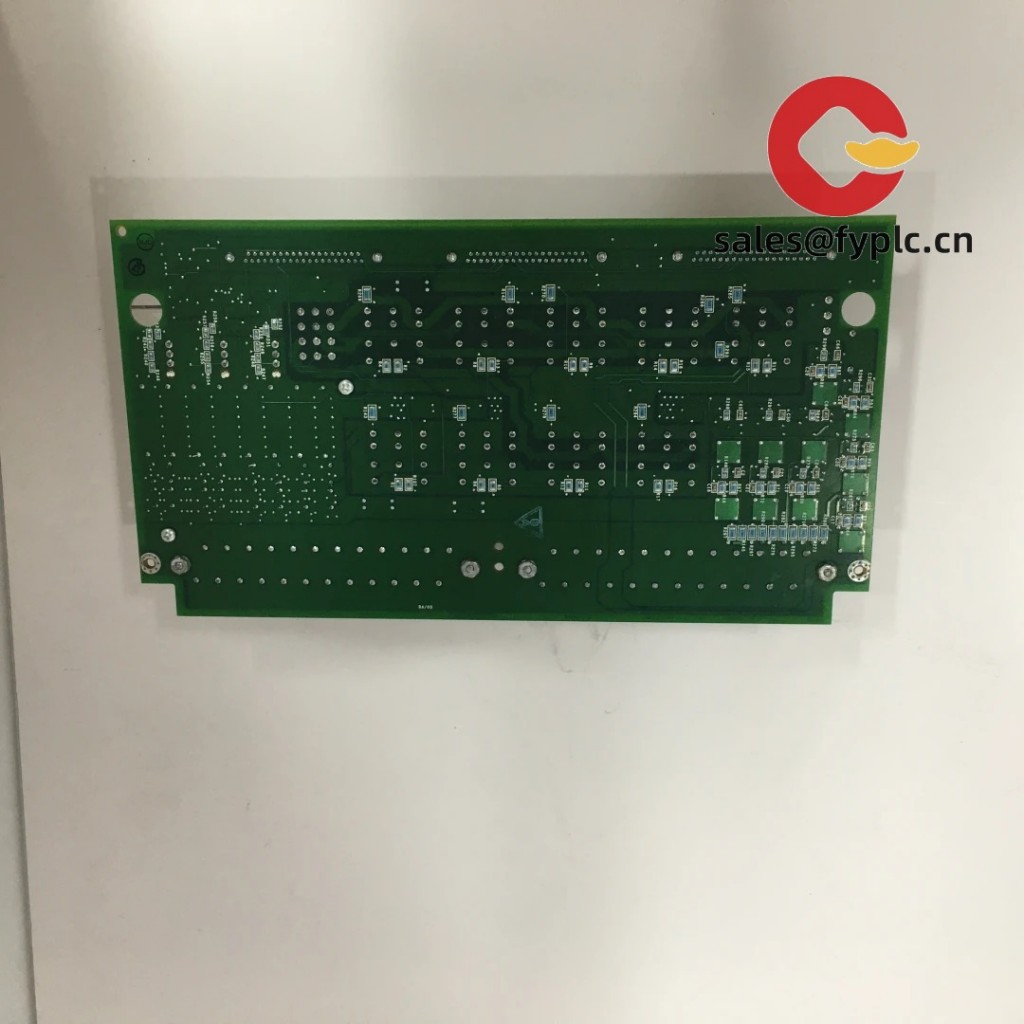

| Installation Method | Standard Mark VIe rack mount (VME-64x compatible); slides into designated slot with locking lever |

Application Fields

This module is almost exclusively found in mechanical protection layers for rotating equipment: steam and gas turbines (especially in ISO base-load plants), hydroelectric governors, large industrial compressors, and critical auxiliary systems like main lube oil pumps. It’s rarely used outside turbine control environments—not because it can’t, but because its certification, timing guarantees, and integration depth are over-engineered for simpler applications. For example, one offshore platform replaced aging electro-mechanical trip relays with IS200TRLYH1BGF units to meet new API RP 14C requirements—and saw trip response time tighten from 85 ms to under 22 ms.

Advantages & Value

- No Re-Certification Headache — Comes with full TÜV-certified FMEDA, proof test procedures, and SIL verification reports. If your plant’s safety case already references Mark VIe components, adding this module doesn’t trigger a full re-assessment.

- Predictable Lifecycle Planning — GE publishes formal obsolescence notices ≥36 months ahead. One customer received early notification about a relay component changeout two years before EOL—giving them time to qualify spares and update maintenance procedures.

- Lower Integration Risk — No drivers, gateways, or custom firmware needed. It appears as a native node in ToolboxST—just assign outputs to logic variables and download. Integrators report cutting commissioning time by 30–50% versus field-wired relay panels.

- Supply Chain Confidence — Unlike some discontinued legacy modules, GE still manufactures and stocks IS200TRLYH1BGF. If ordered today, expect delivery in ≤7 days—if in stock—or no more than four weeks, even with extended warranty or labeling options.

Installation & Maintenance

Mount only in a certified Mark VIe rack with proper grounding (per IEEE 1100). Ensure ambient temperature stays below 70 °C—don’t stack heat-generating modules directly above or below. Wiring must use shielded twisted pair for all output circuits; shields grounded at the module end only. Never share common returns between multiple trip circuits—each relay output should drive its own solenoid or valve coil without daisy-chaining.

For maintenance: perform annual functional tests using ToolboxST’s “Output Force” and “Trip Simulation” tools; verify contact resistance every 2 years (should be <50 mΩ); inspect terminal torque annually. Firmware updates are rare—GE issues them only for critical safety patches, and always includes rollback instructions.

Quality & Certifications

Certified to IEC 61508 SIL 3 (TÜV Rheinland Certificate No. 98 02 30 122 002), UL 508A, CSA C22.2 No. 14, ATEX/IECEx (for non-incendive configurations), and RoHS 3 compliant. Manufactured under ISO 9001:2015 and ISO 13849-1 PL e compliance. MTBF: 158,000 hours (per GE FMEDA v4.2).

Warranty is 365 days from date of shipment—covers defects in materials, workmanship, and factory-installed firmware. Does not cover damage from incorrect wiring, voltage transients exceeding spec, or unauthorized modifications to relay contacts or firmware.

Our Order Placement Process and Guarantees

- Warranty: Full 365-day coverage from shipment date

- Delivery: Typically ships within 1 week if in stock; maximum lead time is 4 weeks—even for units with special labeling or documentation packages

- Payment: 50% advance payment required to initiate order processing; balance due before release for shipping

- Shipping: Fedex, UPS, or DHL express—door-to-door with real-time tracking, insurance, and signature confirmation

Front view highlighting LED status indicators (OK, FAULT, OUTPUT) and module identification label

Rear view showing 16-channel screw-terminal blocks, power input, and HSB connector

Typical installation in a Mark VIe control cabinet with adjacent IS200 controllers and power supplies

Reviews

There are no reviews yet.