Description

GE IS200TRPGH1BDD-S1C5029 – High-Integrity Turbine Protection Generator Module for Mark VIe Systems

The IS200TRPGH1BDD is a specialized, high-integrity protection module in GE’s IS200 series—designed not for general I/O, but specifically to monitor and protect turbine-generator sets in power plants and industrial cogeneration facilities. The “TRPG” stands for Turbine Relay Protection Generator, and the “H1BDD” suffix confirms it’s a SIL 2/3-capable, dual-channel, de-energize-to-trip unit with built-in diagnostics and redundant power inputs. The “S1C5029” denotes a factory-configured variant—typically including pre-loaded firmware revision S1, calibration certificate C5029, and application-specific configuration for generator protection functions like stator earth fault, negative sequence overcurrent, and loss-of-field detection. In practice, this module sits between the generator protection relay (e.g., SEL-487B or GE D60) and the Mark VIe turbine controller—translating protective relay trip commands into deterministic, fail-safe outputs that trigger mechanical shutdowns. One combined-cycle plant in Ohio told us they deployed six of these to replace aging hardwired interlocks—and cut their average trip verification time from 4 hours to under 22 minutes.

Key Features

- Generator-Specific Protection Interface Logic — Pre-programmed to interpret standard generator protection relay outputs (e.g., SEL, GE D60, or Areva P44x) via discrete inputs—and map them to certified trip paths. Includes logic for priority handling (e.g., “overcurrent trip takes precedence over vibration alarm”) and configurable time delays to prevent nuisance trips during transient events.

- Dual-Redundant Power Inputs (BDD) — Accepts two independent 24 VDC supplies (A & B channels), with automatic switchover if one fails. Unlike simple OR-ing diodes, this uses hardware-based voting—so if one supply dips below 18 VDC *and* the other drops simultaneously, the module initiates a controlled safe state rather than floating unpredictably.

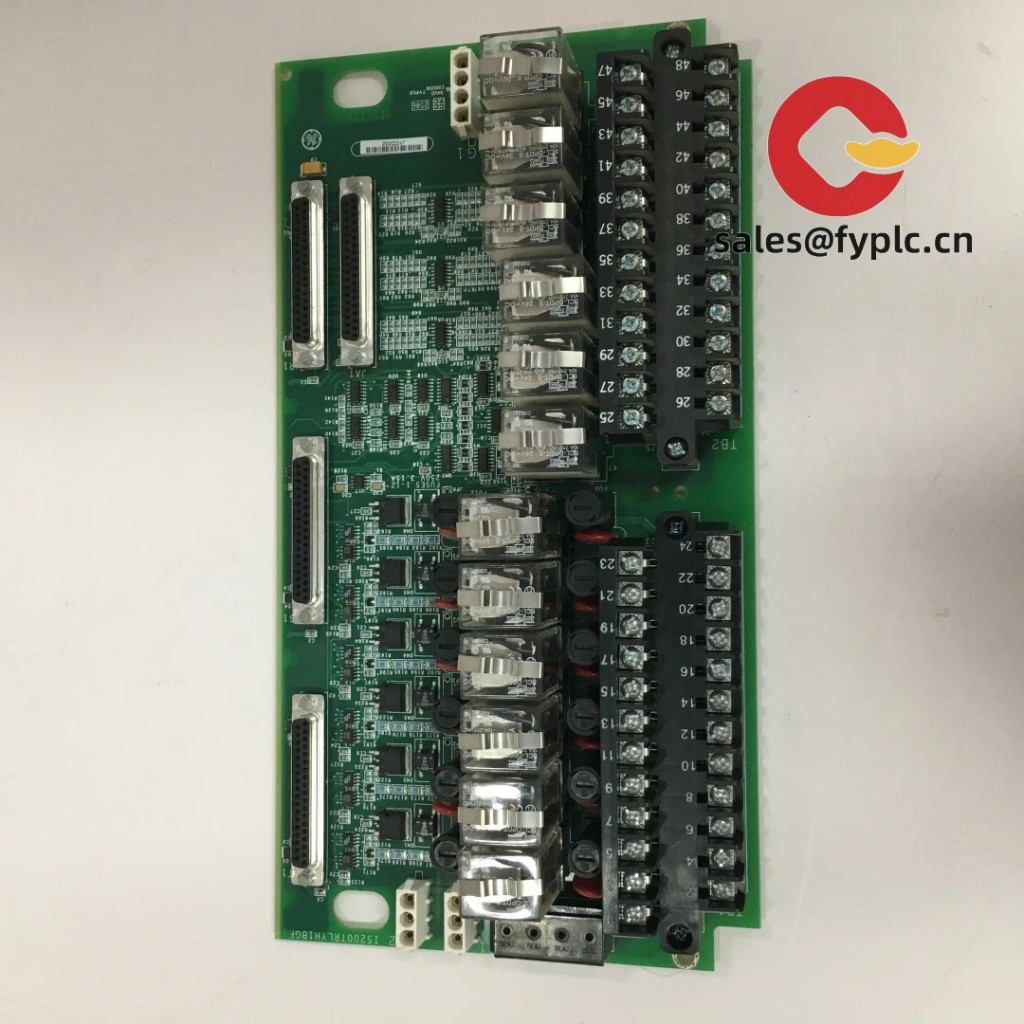

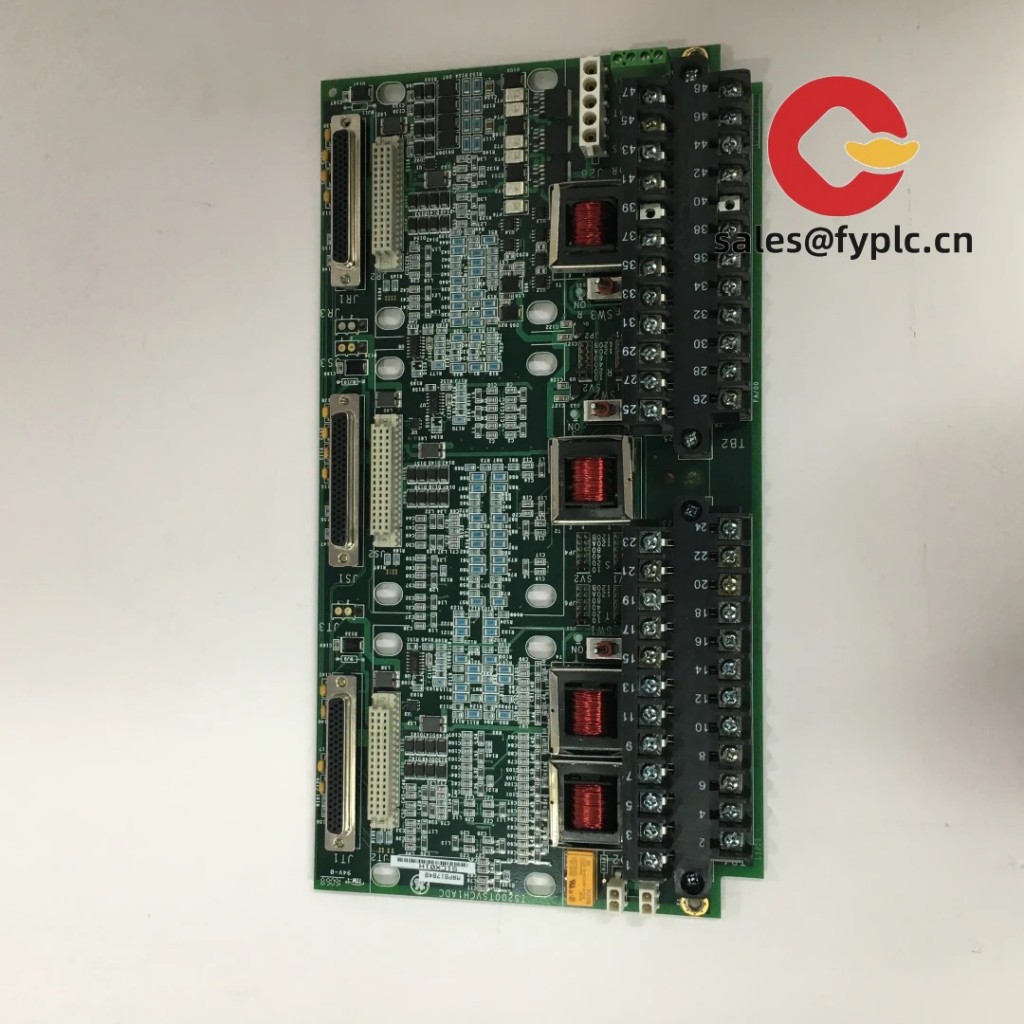

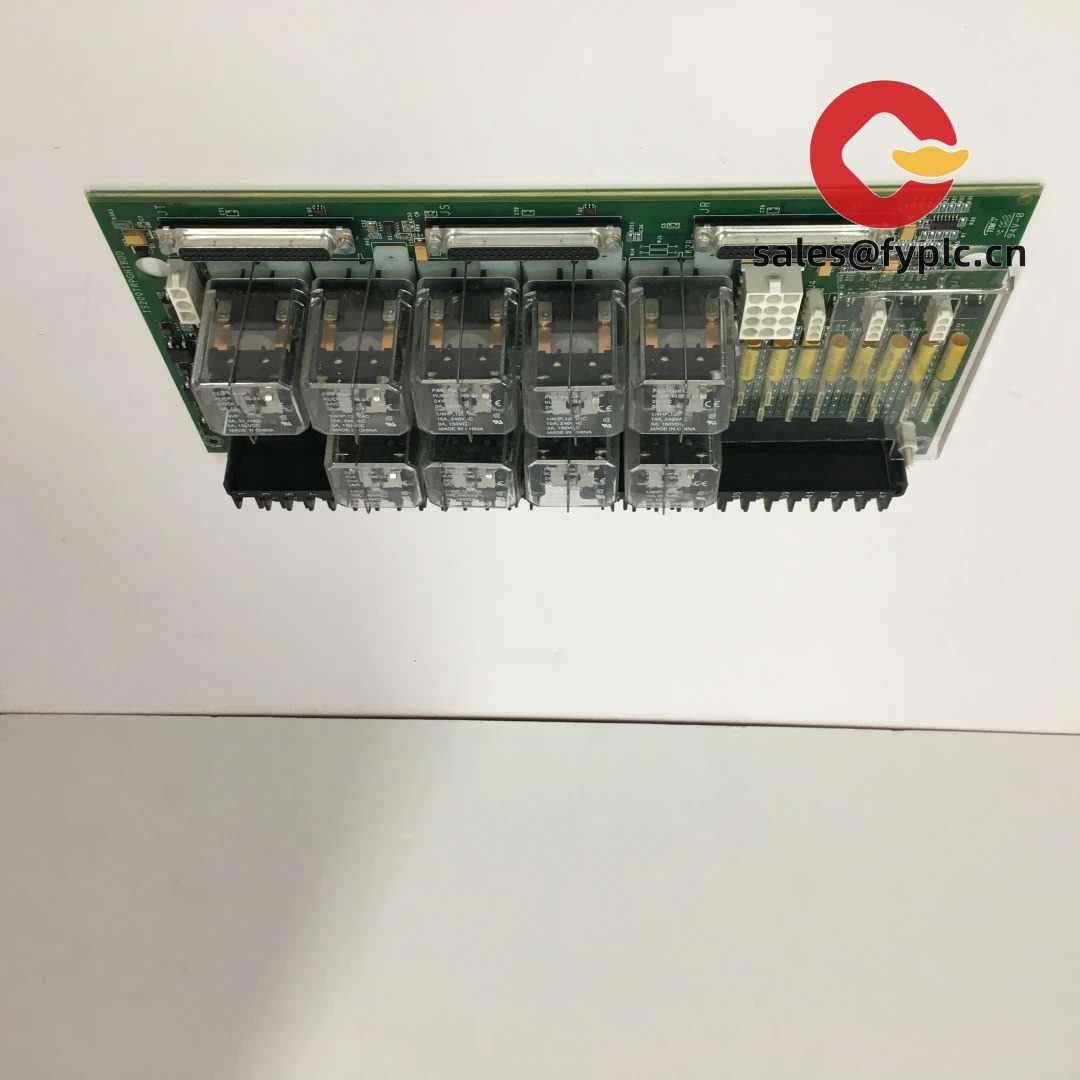

- 16 Isolated Digital Inputs + 8 Form-C Outputs — Inputs are 24 VDC, 5 ms filtered, and rated for 125 VAC transient immunity. Outputs are safety-rated relays (5 A @ 250 VAC), each with welded-contact detection and open-circuit monitoring. The “-S1C5029” version ships with output assignments pre-mapped to common generator trip functions (e.g., Output 1 = Field Breaker Trip, Output 5 = Main Breaker Lockout).

- Native HSB Integration with Mark VIe — Communicates directly over GE’s High-Speed Bus—not Modbus or Ethernet—ensuring sub-10 ms response from input change to output action. This matters when your generator relay detects a stator ground fault and you need mechanical isolation *before* thermal damage occurs.

- Field-Configurable via ToolboxST (No Firmware Flashing Required) — All logic mapping, timing, and diagnostic thresholds are set using GE’s engineering software—not by editing code or loading custom firmware. That means changes can be made during scheduled outages without risk of bricking the unit.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | GE IS200TRPGH1BDD-S1C5029 |

| HS Code | 8537.10.9090 (Programmable controllers, other) |

| Power Requirements | Dual 24 VDC inputs (18–32 VDC each); total consumption ≤ 16 W |

| Dimensions & Weight | 240 × 125 × 225 mm (W×H×D); ~2.7 kg |

| Operating Temperature | −20 °C to +70 °C (operational), −40 °C to +85 °C (storage) |

| Signal Inputs | 16 isolated digital inputs (24 VDC, 5 ms filtering, 125 VAC surge rating) |

| Signal Outputs | 8 isolated Form-C relays (5 A @ 250 VAC / 30 VDC); each with welded-contact and open-circuit detection |

| Communication Interface | HSB (High-Speed Bus) only—requires Mark VIe controller connection via backplane or HSB cable |

| Installation Method | VME-64x compatible rack mount; slides into designated slot in Mark VIe cabinet with mechanical lock |

Application Fields

You’ll find this module almost exclusively in thermal, nuclear, and industrial combined-heat-and-power (CHP) plants where turbine-generator protection must meet strict regulatory requirements (e.g., NRC, ISO 50001, or IEEE 1547). It’s used to bridge legacy generator protection relays with modern turbine control systems—especially in retrofits where replacing the entire protection system isn’t feasible or cost-effective. For example, a pulp & paper mill upgraded its 40-year-old electro-mechanical protection panel with an SEL-487B relay and paired it with three IS200TRPGH1BDD modules to drive field breaker, main breaker, and exciter trip circuits—all while retaining full compliance with NFPA 85 and ANSI C37.90 standards.

Advantages & Value

- No Safety Revalidation Overhead — Ships with TÜV-certified FMEDA reports, proof test procedures, and SIL verification letters. If your site already has Mark VIe-based safety documentation, adding this module typically requires only a minor update—not a full re-certification cycle.

- Faster Commissioning & Troubleshooting — Built-in LED status per channel (INPUT OK, OUTPUT ENERGIZED, FAULT) lets technicians isolate issues in seconds—not hours. One technician in Alberta said he diagnosed a miswired generator earth fault input in under 90 seconds using just the front-panel LEDs.

- Lower Long-Term Spares Risk — GE maintains formal component obsolescence roadmaps for IS200 modules. The S1C5029 variant was introduced in Q2 2023 and is scheduled for minimum production through 2029—with spare parts availability guaranteed through 2032.

- Supply Chain Certainty — Unlike some discontinued IS200 variants, TRPGH1BDD remains in active production and stocked regionally. Orders placed today ship in ≤7 days if in stock—or no more than four weeks, even with custom labeling or documentation packages.

Installation & Maintenance

Install only in a grounded Mark VIe cabinet meeting IEEE 1100 standards. Maintain ≥75 mm clearance above/below for convection cooling. Input wiring must use shielded twisted pair, with shields terminated at the module end only. Never share return paths between protection relay outputs and other DC sources—each input should have its own dedicated return to avoid ground loops.

For maintenance: perform annual functional tests using ToolboxST’s “Input Force” and “Output Test” utilities; verify contact resistance every 2 years (<50 mΩ); inspect terminal torque annually. Firmware updates are issued sparingly—only for critical safety patches—and always include rollback instructions and compatibility notes.

Quality & Certifications

Certified to IEC 61508 SIL 3 (TÜV Rheinland Certificate No. 98 02 30 122 003), UL 508A, CSA C22.2 No. 14, ATEX/IECEx Zone 2 (non-incendive), and RoHS 3 compliant. Complies with IEEE C37.90.1 (surge immunity), IEC 61000-4-5 (lightning surge), and ISO 13849-1 PL e. MTBF: 164,000 hours (per GE FMEDA v4.3).

Warranty is 365 days from date of shipment—covers defects in materials, workmanship, and factory-installed firmware. Excludes damage from incorrect wiring, voltage transients exceeding spec, or unauthorized modifications to hardware or configuration.

Our Order Placement Process and Guarantees

- Warranty: Full 365-day coverage from shipment date

- Delivery: Typically ships within 1 week if in stock; maximum lead time is 4 weeks—even for units with custom firmware load, labeling, or documentation bundles

- Payment: 50% advance payment required to initiate order processing; remaining 50% due before dispatch

- Shipping: Fedex, UPS, or DHL express—door-to-door with real-time tracking, insurance, and signature confirmation

Front view highlighting input/output status LEDs and factory-applied S1C5029 identification label

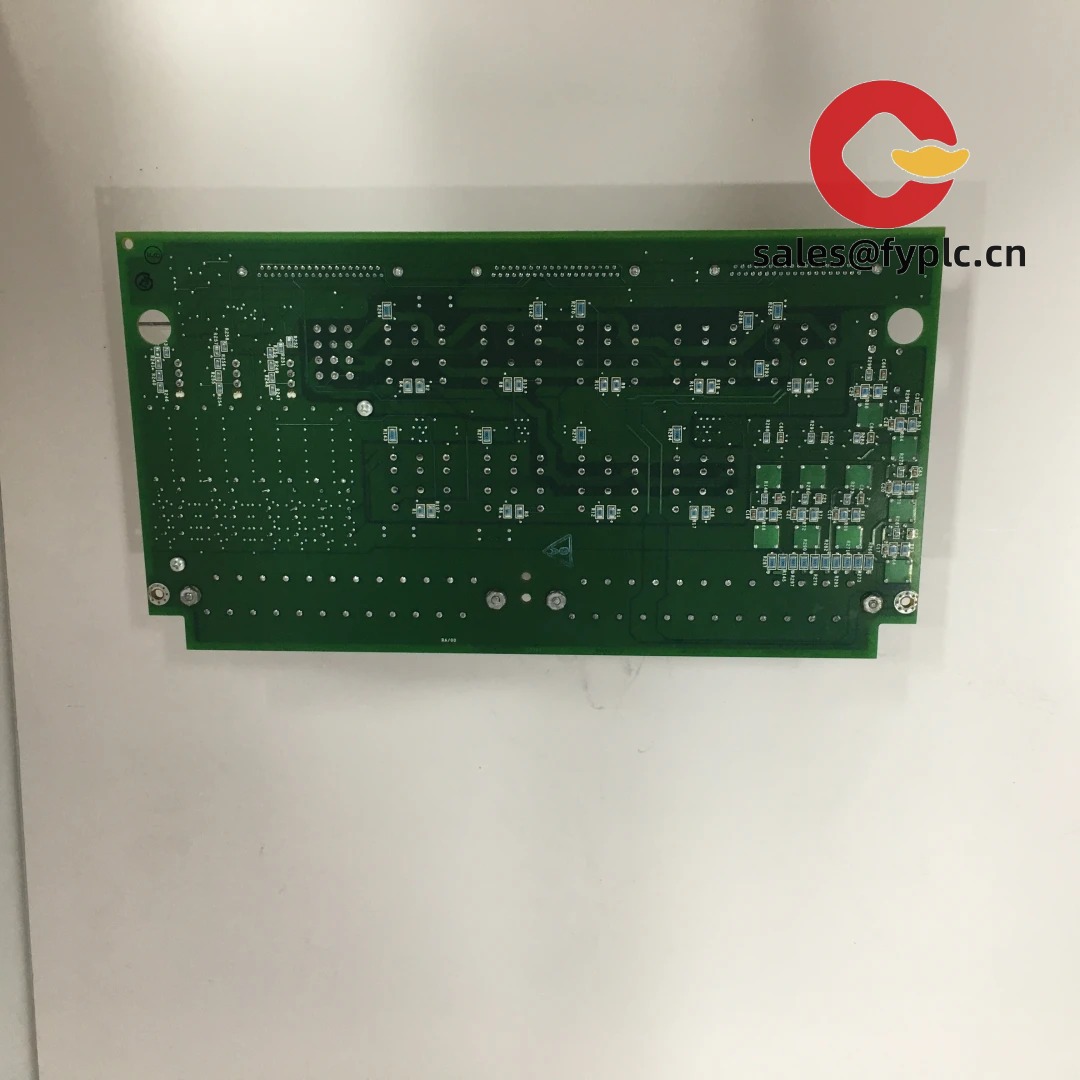

Rear view showing dual 24 VDC power terminals, 16-channel input block, and 8-output relay block

Reviews

There are no reviews yet.