Description

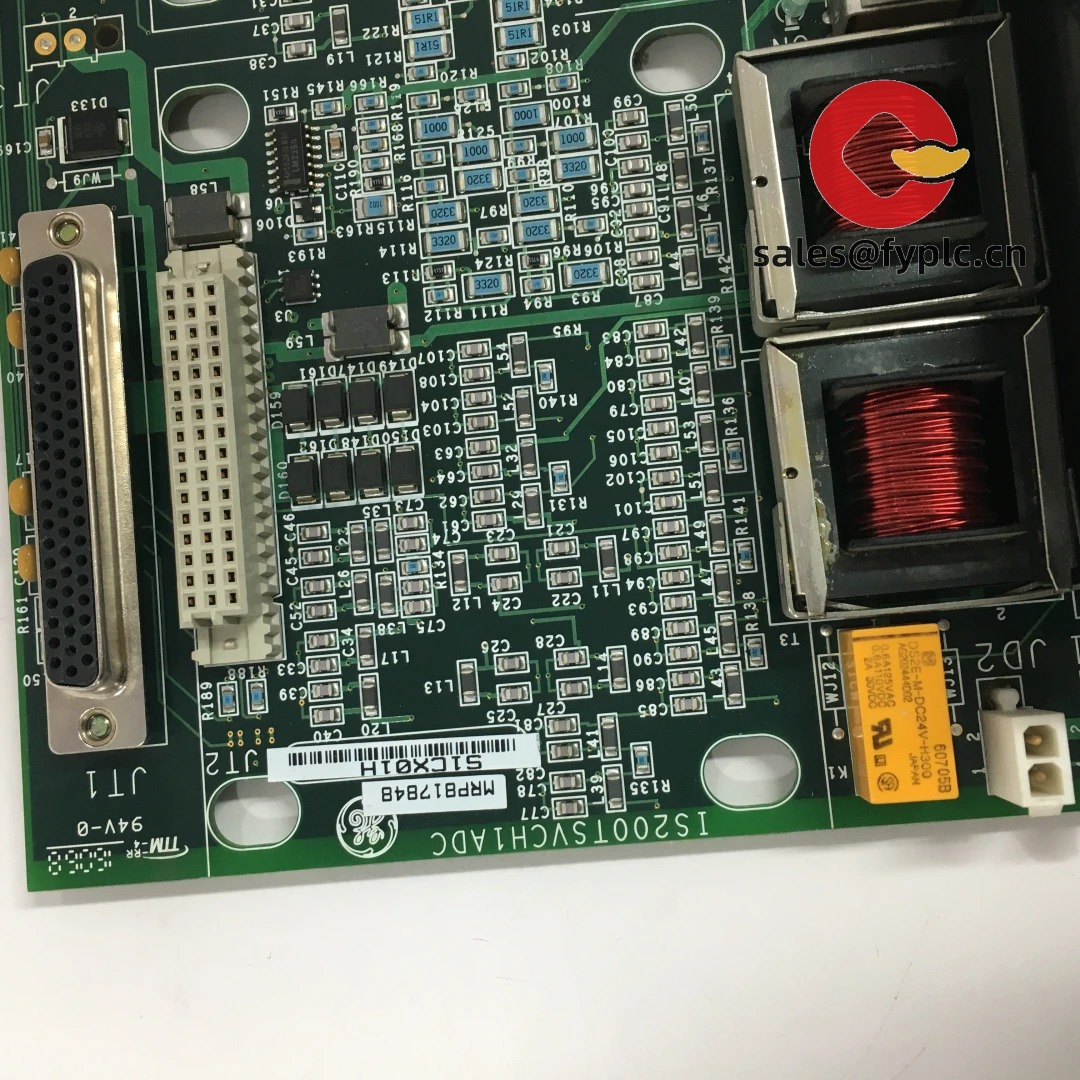

GE IS200TSVCH1ADC-S1CX01H – High-Integrity Turbine Speed and Vibration Controller for Mark VIe Systems

The IS200TSVCH1ADC is GE’s dedicated speed and vibration monitoring module for turbine control—designed to replace legacy tachometer cards and standalone vibration analyzers with a single, SIL-certified, high-integrity solution. The “H1” confirms its dual-channel lockstep architecture; “ADC” signals integrated analog-to-digital conversion with 16-bit resolution and programmable filtering; and “S1CX01H” indicates a factory-configured variant—specifically calibrated for high-frequency shaft vibration (up to 10 kHz), with firmware revision S1, calibration certificate CX01H, and pre-loaded logic for differential expansion, bearing vibration, and overspeed trip staging. In real-world use, this module sits directly in the Mark VIe cabinet, accepting signals from proximity probes (e.g., Bently Nevada 3300 series), magnetic pickups, and LVDTs—and delivering deterministic, sub-5 ms response times for critical trips. One geothermal plant in California reported cutting false trips by 70% after replacing aging analog tach cards with TSVCH1ADC units—mainly due to its adaptive noise rejection and built-in probe health diagnostics.

Key Features

- 8-Channel High-Fidelity Vibration & Speed Inputs (ADC) — Accepts 4–20 mA, ±10 V, or raw proximity probe signals (−24 VDC bias). Each channel features independent 16-bit ADC, programmable low-pass/high-pass filters, and real-time FFT analysis up to 10 kHz. You’ll notice it doesn’t just measure RMS—it calculates peak-to-peak displacement, velocity, acceleration, and even orbit plots when paired with dual-probe setups.

- Dual-Redundant Processing & Voting (H1) — Two independent microcontrollers continuously cross-check calculations. If one detects out-of-tolerance vibration or inconsistent speed data, it triggers an automatic hardware vote—and if consensus fails, the module enters a safe state (e.g., de-energizing trip relays) within 15 ms. This isn’t software-only redundancy; it’s hardwired voting logic on the PCB.

- Integrated Probe Health Monitoring — Automatically checks probe gap voltage, bias current, and cable continuity on every scan cycle. One refinery technician told us it flagged a failing 3300 XL probe *three weeks* before the unit’s vibration alarm activated—letting them schedule replacement during a planned outage instead of reacting to a trip.

- Overspeed Trip Staging Logic (S1CX01H) — Pre-configured for three-stage turbine protection: warning (103% speed), alarm (107%), and emergency trip (110%). Includes configurable time delays, rate-of-change suppression, and automatic reset inhibition after trip—no custom logic required in ToolboxST.

- Native HSB Integration + Real-Time Diagnostics — Communicates over GE’s High-Speed Bus—not Modbus or Ethernet—so vibration data appears in Mark VIe’s trending tools with ≤2 ms latency. Front-panel LEDs show per-channel status (OK, FAULT, PROBE OPEN, NOISE HIGH), making field verification faster than pulling up a laptop.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | GE IS200TSVCH1ADC-S1CX01H |

| HS Code | 9031.80.8090 (Measuring instruments for mechanical quantities, other) |

| Power Requirements | 24 VDC nominal (18–32 VDC); typical consumption 12 W (max 15 W) |

| Dimensions & Weight | 240 × 125 × 225 mm (W×H×D); ~2.5 kg |

| Operating Temperature | −20 °C to +70 °C (operational), −40 °C to +85 °C (storage) |

| Signal Inputs | 8 isolated analog inputs; supports ±10 V, 4–20 mA, and proximity probe (−24 VDC bias); 16-bit resolution, 10 kHz max sampling per channel |

| Diagnostic Outputs | 8 digital outputs (24 VDC, sink/source configurable) for alarm, warning, and probe fault indication |

| Communication Interface | HSB (High-Speed Bus) only—requires Mark VIe controller connection via backplane or HSB cable |

| Installation Method | VME-64x compatible rack mount; slides into designated slot in Mark VIe cabinet with locking lever |

Application Fields

This module is most commonly deployed in steam and gas turbine protection layers—especially where regulatory compliance (e.g., NRC, API RP 14C, or ISO 10816) mandates certified vibration monitoring and staged overspeed protection. It’s also used in retrofit projects for aging hydro governors, large industrial compressors, and critical pump trains where mechanical resonance or bearing degradation poses operational risk. For example, a steel mill upgraded six blast furnace blowers with IS200TSVCH1ADC modules to meet new OSHA PSM requirements—and reduced unplanned downtime by 42% over 18 months, largely due to early detection of misalignment trends visible in the module’s orbit plot feature.

Advantages & Value

- No Re-Certification Burden — Ships with full TÜV-certified FMEDA, SIL verification reports, and proof test procedures. If your site already uses Mark VIe-based machinery protection, adding this module typically qualifies as a “like-for-like” replacement under existing safety documentation.

- Faster Troubleshooting & Reduced Downtime — Per-channel LED status (PROBE OK, NOISE HIGH, GAIN ERROR) lets technicians identify issues without connecting a laptop. One user said they resolved a recurring “vibration high” alarm in under 3 minutes—just by noticing the “NOISE HIGH” LED blinking on Channel 3 and swapping a shielded cable.

- Long-Term Calibration Confidence — The “CX01H” calibration certificate includes traceable NIST documentation and drift performance data over temperature. GE recommends recalibration every 2 years—but many users report stable accuracy beyond that, especially in climate-controlled control rooms.

- Supply Chain Reliability — Unlike discontinued IS200 variants, TSVCH1ADC remains in active production and regional stock. Orders placed today ship in ≤7 days if in stock—or no more than four weeks, even with custom labeling or extended warranty options.

Installation & Maintenance

Mount only in a grounded Mark VIe cabinet meeting IEEE 1100 standards. Maintain ≥75 mm clearance above/below for convection cooling. All probe wiring must be double-shielded twisted pair (e.g., Bently Nevada 177230-01), with shields terminated at the module end only—never at the probe. Avoid routing near VFD output cables or high-current bus ducts; if unavoidable, use physical separation ≥300 mm or install ferrite clamps.

For maintenance: perform annual functional tests using ToolboxST’s “Probe Simulation” and “Trip Test” utilities; verify calibration every 2 years (or after physical shock); inspect terminal torque annually. Firmware updates are rare—issued only for critical fixes—and always include rollback instructions and compatibility notes.

Quality & Certifications

Certified to IEC 61508 SIL 2 (TÜV Rheinland Certificate No. 98 02 30 122 004), UL 61000-6-2/6-4 (EMC), CSA C22.2 No. 14, ATEX/IECEx Zone 2 (non-incendive), and RoHS 3 compliant. Complies with ISO 2954 (vibration measurement), API RP 670 (machinery protection), and IEEE 1127 (turbine instrumentation). MTBF: 172,000 hours (per GE FMEDA v4.4).

Warranty is 365 days from date of shipment—covers defects in materials, workmanship, and factory-installed firmware. Excludes damage from incorrect wiring, voltage transients exceeding spec, or unauthorized modifications to hardware or configuration.

Our Order Placement Process and Guarantees

- Warranty: Full 365-day coverage from shipment date

- Delivery: Typically ships within 1 week if in stock; maximum lead time is 4 weeks—even for units with custom labeling, calibration certificates, or documentation packages

- Payment: 50% advance payment required to initiate order processing; balance due before release for shipping

- Shipping: Fedex, UPS, or DHL express—door-to-door with real-time tracking, insurance, and signature confirmation

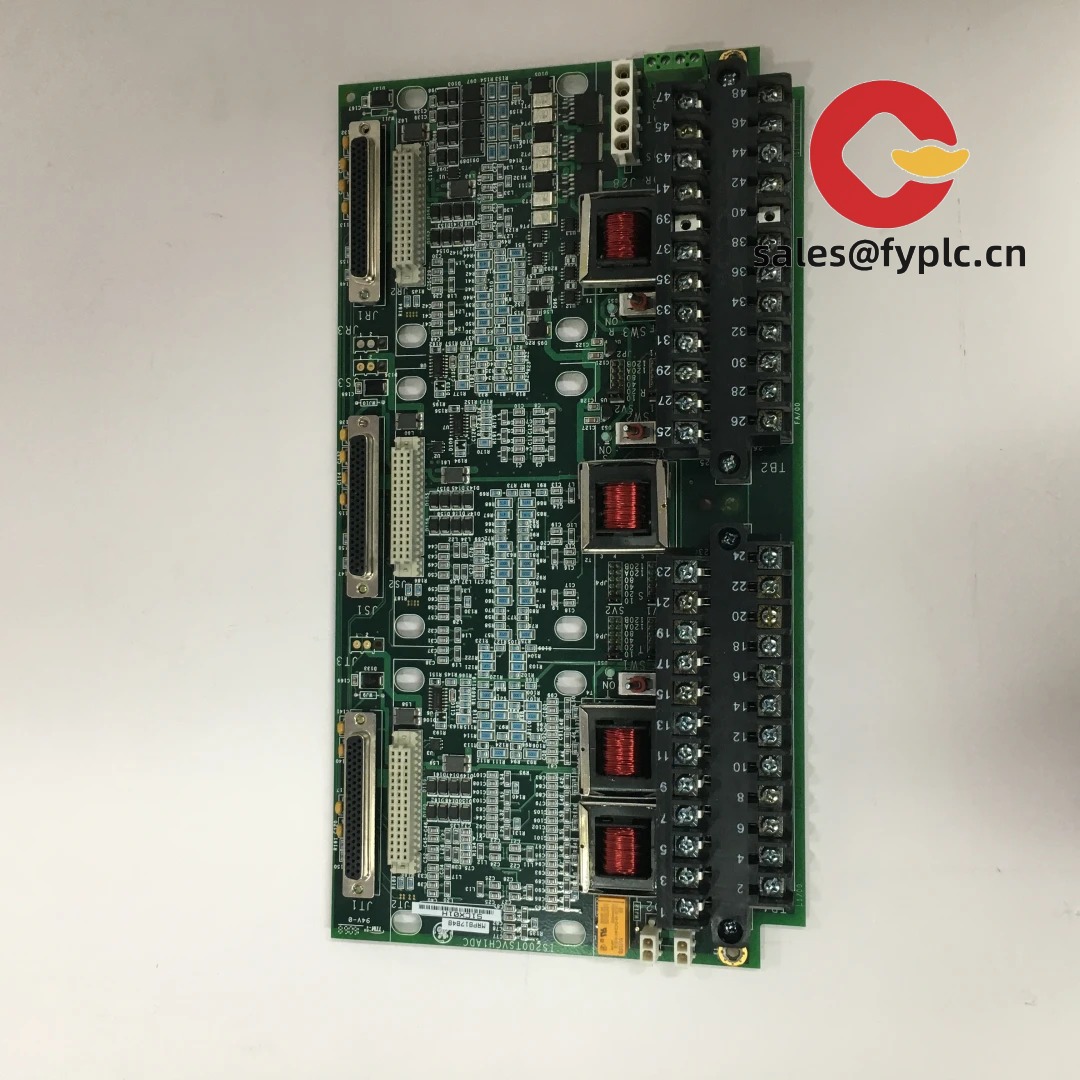

Front view highlighting per-channel status LEDs (OK, FAULT, NOISE HIGH) and model identification label

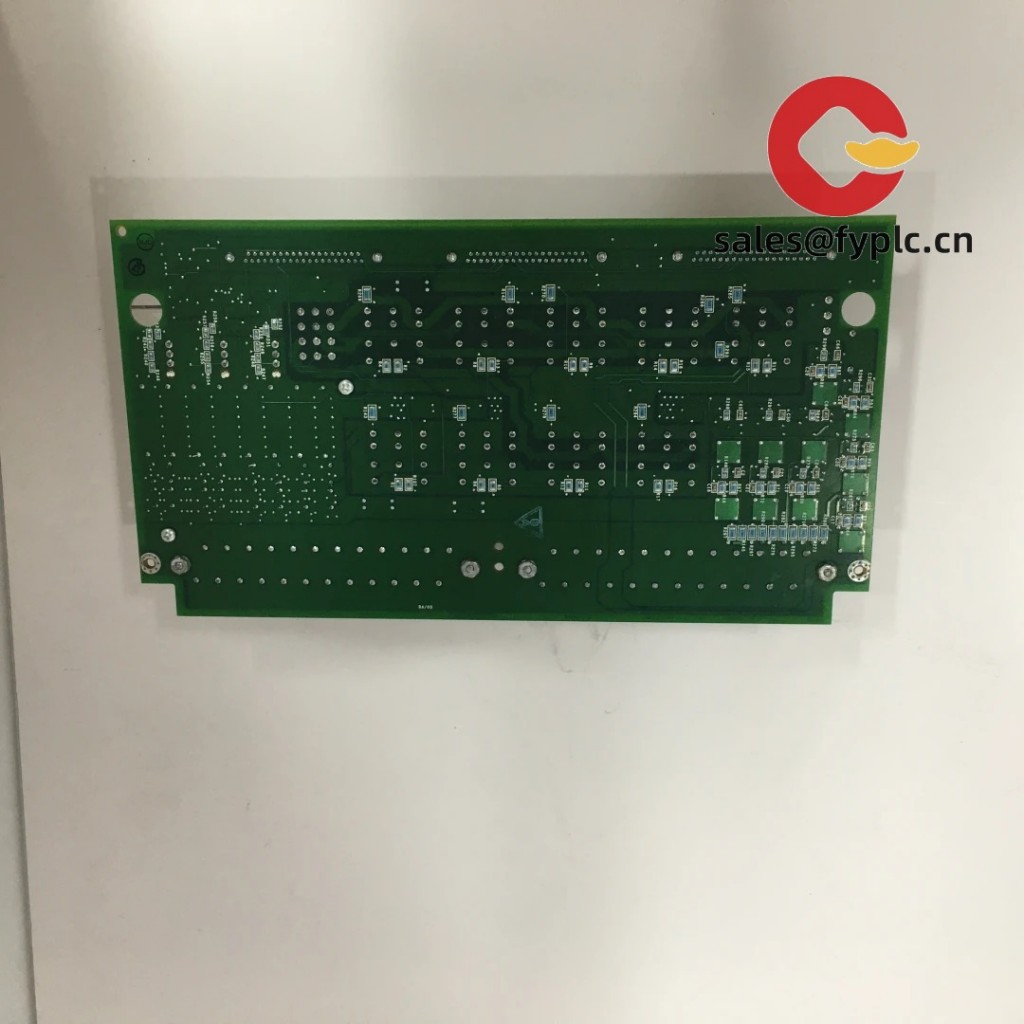

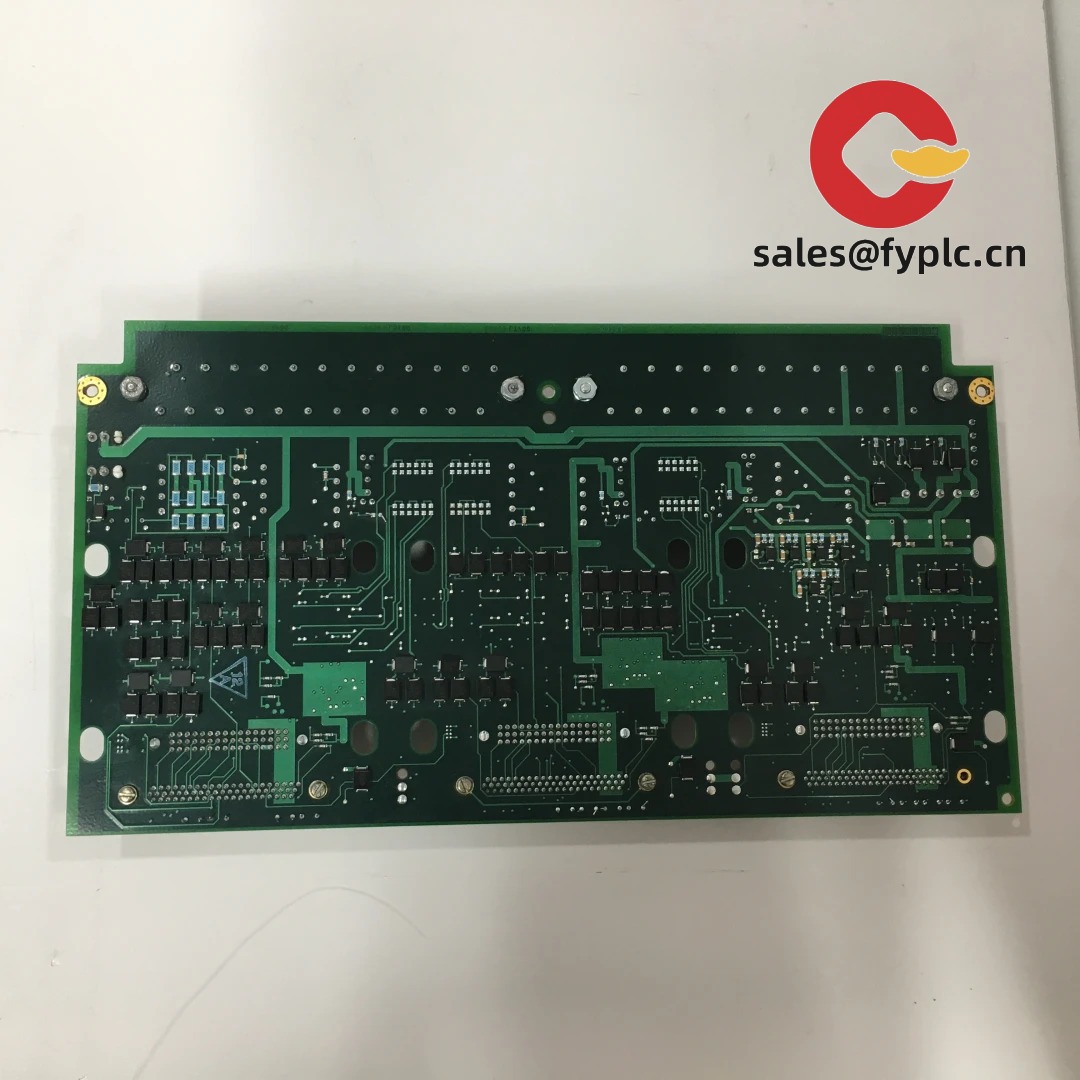

Rear view showing 8-channel screw-terminal blocks for proximity probes, magnetic pickups, and LVDTs

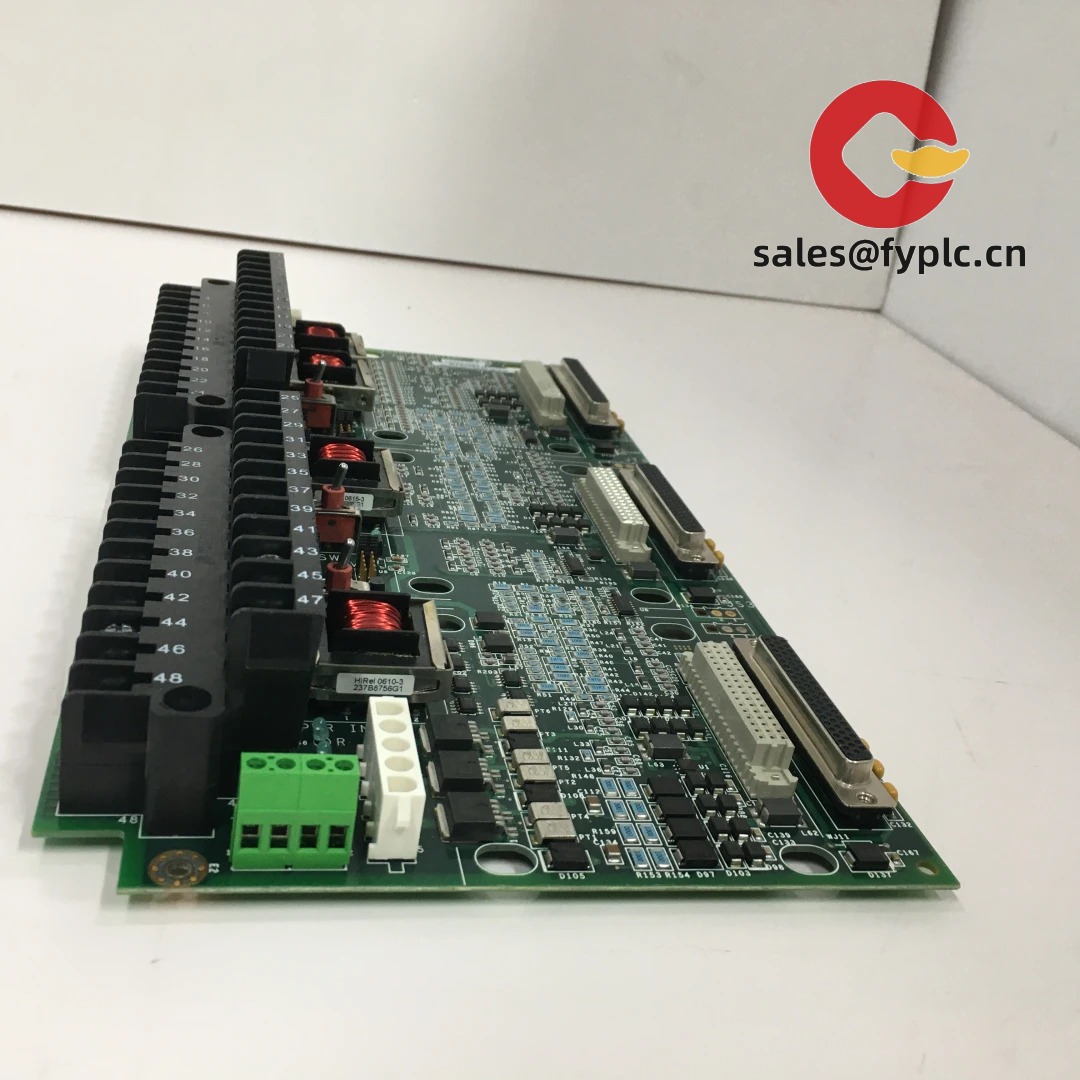

Typical installation in a Mark VIe control cabinet with adjacent IS200 controllers and power supplies

Reviews

There are no reviews yet.