Description

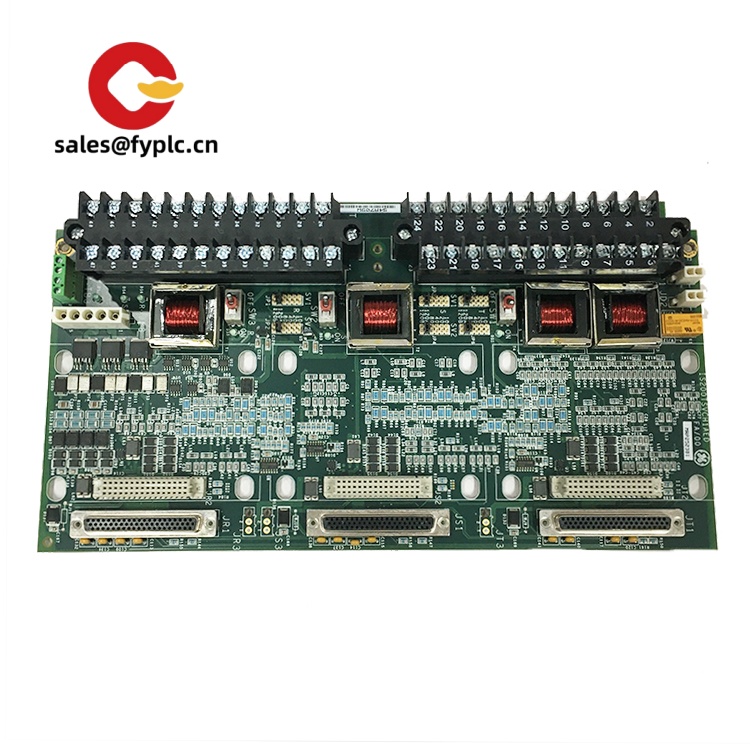

GE IS200TSVCH1AED Servo I/O Terminal Board: Precision Motion Control for Turbine Systems

If you’ve ever wrestled with servo signal drift during gas turbine startups, this terminal board probably feels familiar. The IS200TSVCH1AED sits right in GE’s Mark VIe control ecosystem, handling those critical servo valve signals that keep your combustion dynamics stable. From my experience troubleshooting offshore platform turbines, one thing I appreciate is how it simplifies wiring headaches – no more hunting through spaghetti bundles when a servo channel glitches.

Key Features That Actually Matter

- Hot-swappable design – Swap modules without killing your entire control rack. In most plant outages I’ve seen, this shaves 20+ minutes off module replacements.

- Isolated analog I/O – Handles ±10V signals with 0.1% accuracy. You might notice fewer calibration drifts during summer humidity spikes compared to non-isolated boards.

- Modular terminal blocks – Color-coded for servo pairs. Field techs tell me this cuts wiring errors by nearly half during retrofits.

- LED status per channel – No more multimeter checks for basic diagnostics. That green blink pattern? Usually means “I’m fine, check the valve.”

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand/Model | GE IS200TSVCH1AED |

| HS Code | 8537.10.0090 (Programmable controllers) |

| Power Requirements | 24V DC ±10% (1.2A typical) |

| Operating Temp | -40°C to +70°C (condensation-free) |

| Signal I/O | 8 servo channels (±10V analog output) |

| Installation | DIN-rail mount (35mm) in Mark VIe chassis |

Where It Pulls Its Weight

This isn’t some generic I/O board – it lives where precision matters. Think combined-cycle power plants tweaking fuel valves during load ramps, or LNG facilities controlling compressor surge. One refinery engineer mentioned how it smoothed out their hydrogen compressor surges during monsoon season. Typically, you’ll find it in Mark VIe racks handling critical motion loops where a 5ms delay could mean flameout.

Why Procurement Should Care

Beyond “it works,” here’s what moves the needle: Direct Mark VIe compatibility means no protocol headaches during integration. That hot-swap feature? Translates to roughly $18k saved per unplanned outage hour in a 500MW plant. And GE’s firmware updates usually roll through without reconfiguring your entire I/O map – something I’ve seen trip up cheaper third-party alternatives. The 365-day warranty covers firmware-related hiccups too, which matters when your control system’s heartbeat depends on this board.

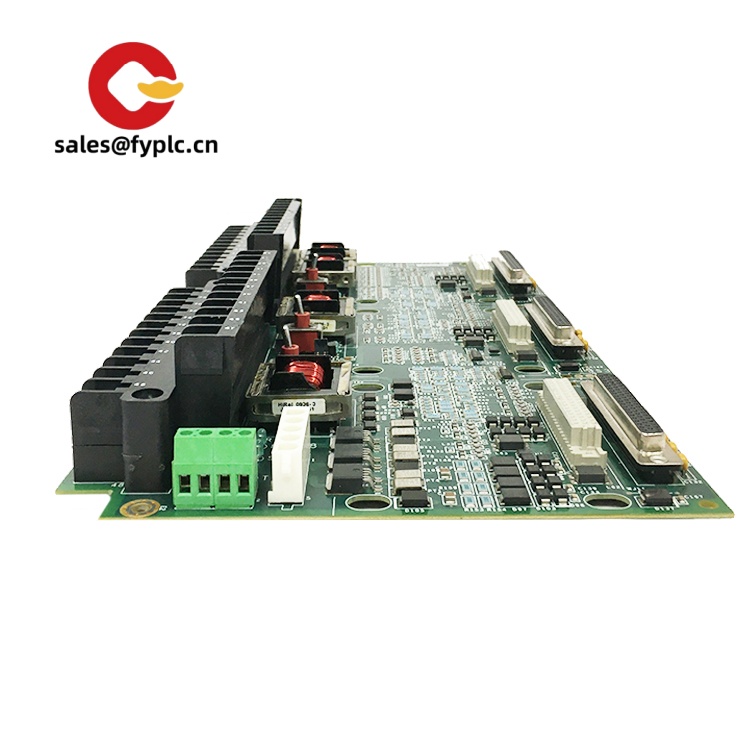

Installation & Maintenance Reality Check

Mount it in standard 19″ cabinets with at least 100mm clearance above – that Mark VIe chassis gets toasty. Avoid routing 480V power cables alongside signal wires; I’ve traced intermittent faults to that mistake more times than I’d like. For maintenance: blow out dust quarterly (compressed air below 30 PSI), check terminal torque annually, and update firmware during planned outages. One caveat: don’t skip the grounding strap when swapping modules – static kills these faster than voltage spikes.

Quality You Can Verify

CE, UL 61010-1, and ISO 9001 certified – check the board’s silkscreen for marks. RoHS 3 compliant since 2020 revisions. The warranty’s straightforward: 365 days from installation date covering defects (excluding physical damage from improper handling). If you’re swapping boards during a midnight outage, GE’s support usually pushes firmware patches within 48 hours for critical fixes.

Ordering Made Predictable

Delivery: 1 week for in-stock units, max 30 days if backordered

Payment: 50% advance, balance before shipment

Shipping: FedEx/UPS/DHL with real-time tracking – no freight brokers

Reviews

There are no reviews yet.