Description

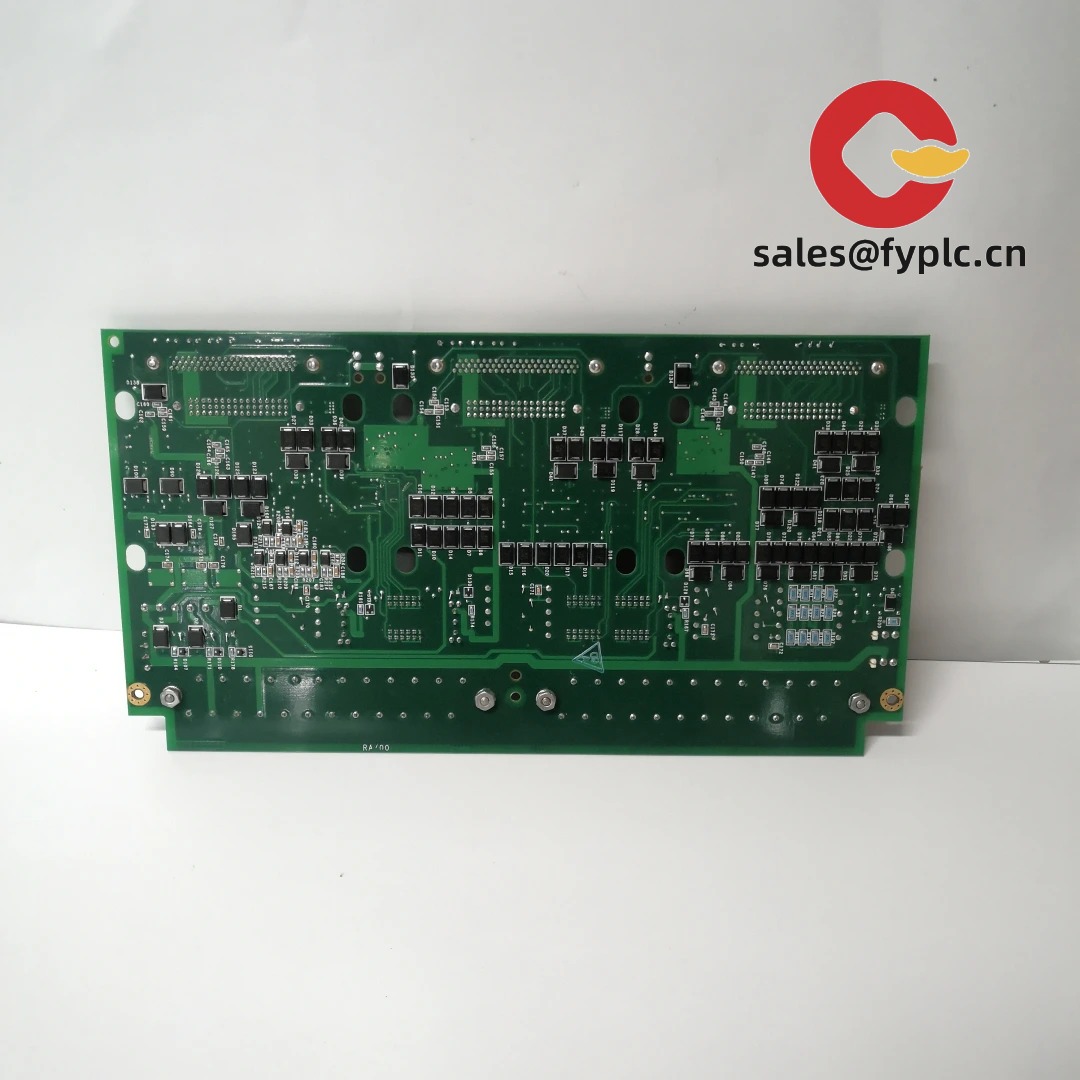

GE IS200TSVCH2AED — High-Resolution Turbine Speed & Vibration Input Module for Mark VIe Control Systems

Let’s cut to the chase: if you’re maintaining or upgrading a GE Mark VIe turbine control system—and especially if vibration monitoring, overspeed protection, or dual-channel speed redundancy matters to your plant’s uptime—this module isn’t just another I/O card. It’s one of the more tightly integrated, field-proven analog input modules GE built for critical rotating equipment applications.

One thing I appreciate is how it handles signal conditioning *onboard*: no external signal conditioners needed for most proximity probe or magnetic pickup inputs. That cuts panel space, wiring complexity, and potential failure points—especially in retrofit projects where cabinet real estate is tight.

Key Features

- Dual independent vibration channels — Each accepts ±10 VDC or 4–20 mA inputs from proximity probes (e.g., Bently Nevada 3300 series) or velocity transducers, with configurable high-pass/low-pass filtering and RMS/Peak detection.

- Triple redundant speed inputs — Supports three magnetic pickup or Hall-effect sensors per channel (A/B/Z), with automatic failover and phase-difference diagnostics—critical for overspeed trip logic compliance (IEC 61508 SIL2).

- Onboard isolation & diagnostics — 2500 Vrms channel-to-bus isolation; self-test at power-up and continuous health monitoring (open-circuit, short-circuit, out-of-range alerts reported via CIMPLICITY or ToolboxST).

- Mark VIe-native integration — Plug-and-play with the VME backplane; firmware auto-recognized by the controller—no manual DIP-switch configuration or jumpering required (unlike older TSV modules).

- Hot-swappable with retained configuration — Replace without shutting down the controller; settings persist in non-volatile memory, so calibration and scaling stay intact.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | General Electric / IS200TSVCH2AED-MRP246517 |

| HS Code | 8537.10.90 — Boards, panels for industrial control systems (US HTS) |

| Power Requirements | Supplied via VME backplane (±5 VDC, +12 VDC); typical draw: 1.8 W |

| Dimensions & Weight | 19.5 cm × 12.7 cm × 3.8 cm (7.7″ × 5.0″ × 1.5″); ~380 g |

| Operating Temperature | 0 °C to +60 °C (derated above 50 °C; not rated for outdoor or turbine hood mounting) |

| Signal Input Types | Vibration: ±10 VDC (differential), 4–20 mA (sinking/source); Speed: 0.1–20 kHz magnetic pickup (with built-in integrator & squaring), Hall-effect, TTL |

| Communication Interface | VME64x bus (32-bit, 40 MHz); communicates directly with Mark VIe controllers (TMR or simplex) |

| Installation Method | Standard 6U VME chassis slot (requires compatible backplane & cooling); front-panel LED status indicators |

Application Fields

This module shows up most often where mechanical integrity meets regulatory scrutiny: gas turbine compressor stations (especially on pipeline grid balancing units), combined-cycle power plants running on GE 7HA/9FB platforms, and large industrial steam turbines in petrochemical refineries. From my experience, it’s frequently specified when customers are replacing legacy TSI systems that lacked phase analysis or dual-channel correlation—say, moving from a standalone Bently 3500 rack to integrated Mark VIe-based monitoring. One customer in Texas told us they cut their annual vibration-related forced outages by ~40% after switching to this module’s real-time orbit analysis and trigger-synchronized capture.

Advantages & Value

Procurement-wise, it’s rarely about lowest unit price—it’s about reducing total cost of ownership over 10+ years. This module avoids costly re-engineering because it reuses existing Mark VIe firmware libraries and ToolboxST configuration tools. Compatibility with standard GE diagnostic cables (e.g., IS200CBLAH1A) means no custom harnesses. And since it shares the same VME form factor and thermal profile as other IS200-series cards, cabinet airflow and spacing calculations don’t need revisiting. In many cases, engineering hours saved during commissioning offset the hardware premium within the first outage cycle.

Installation & Maintenance

Mount only in a properly grounded, filtered, and ventilated Mark VIe-rated VME chassis—minimum 200 LFM airflow recommended. Avoid installing adjacent to high-EMI modules (e.g., servo output cards) without the optional metal shielding kit (IS200SHLDH1A). Wiring must use twisted-pair shielded cable, with shields terminated at the module end only (floating at sensor end for proximity probes). Safety note: always isolate the VME backplane and verify zero voltage before insertion/removal—even though it’s hot-swappable, arc-flash risk exists under fault conditions.

Routine maintenance is minimal: clean dust filters quarterly; verify calibration annually using a certified signal source (e.g., Fluke 726); firmware updates are rare but advised before major controller upgrades—GE typically bundles them with Mark VIe Service Packs (v7.20+ includes full TSVH2AED support). No potentiometers or jumpers to adjust—everything’s software-configured.

Quality & Certifications

Certified to UL 508A (Industrial Control Panels), CE (2014/30/EU EMC Directive & 2011/65/EU RoHS), and compliant with IEC 61000-6-2/-4 for industrial immunity. Meets GE’s internal QAP-1200 reliability standard (MTBF > 120,000 hrs). Backed by a full 365-day warranty—covers parts and labor for field-replaceable defects, including firmware-related functional failures. Replacement units ship pre-flashed and pre-tested.

Our Order Placement Process & Guarantees:

- Warranty period: 365 days from shipment date

- Delivery time: 1 week for in-stock units; no longer than 30 days for special builds

- Payment: 50% advance, balance due before dispatch

- Shipping: FedEx, UPS, or DHL Express — fully insured, with real-time tracking

Reviews

There are no reviews yet.