Description

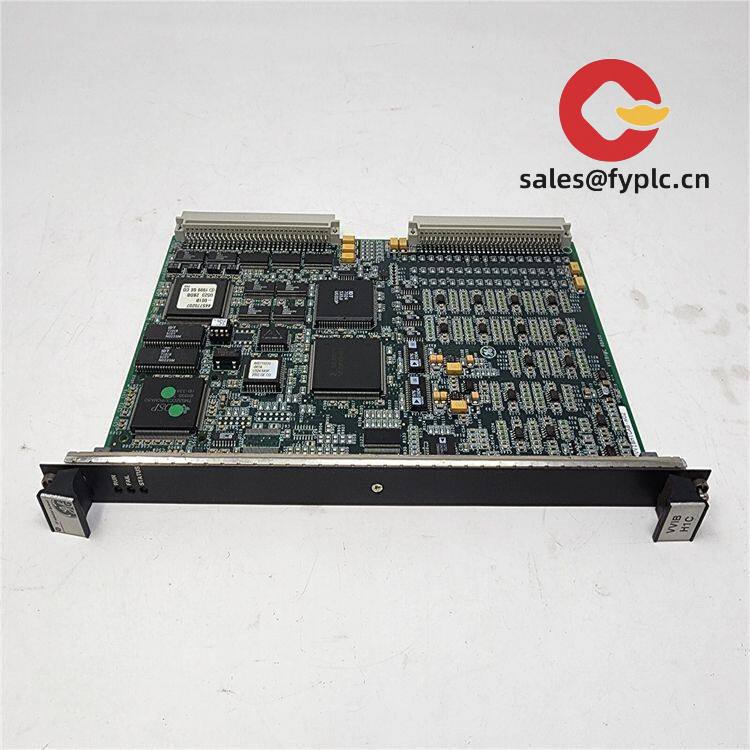

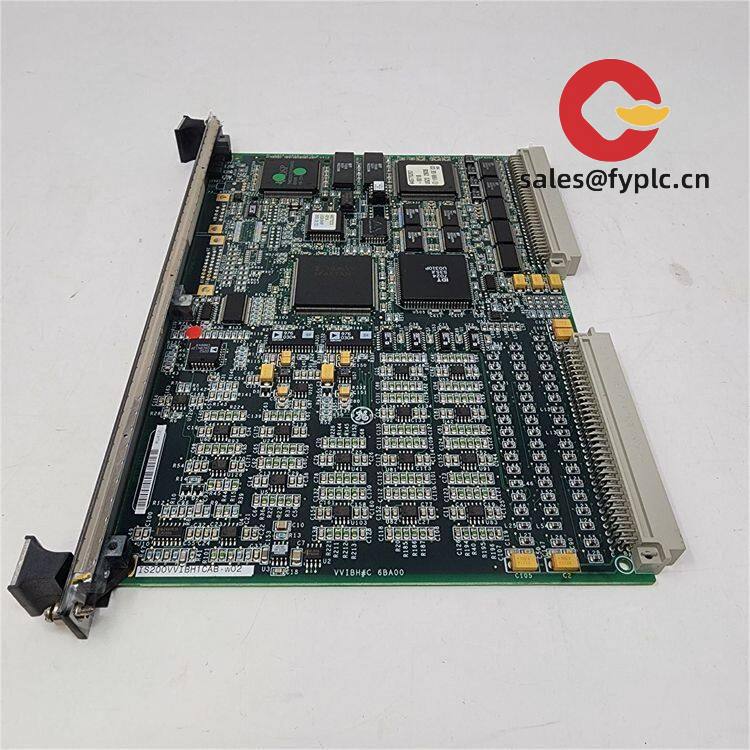

GE IS200VVIBH1CAB-W02: Your Turbine Vibration Monitoring Workhorse

When turbine vibrations start whispering trouble, this GE module listens closely. I’ve seen it catch bearing wear in power plants before operators even noticed unusual noise. One thing I appreciate is how it handles eight vibration channels simultaneously without breaking a sweat – typically in Mark VIe turbine control cabinets where every millisecond counts.

Why field engineers keep it in their toolkit

- 8-channel analog input/output – processes signals from accelerometers and proximity probes in real-time, so you’re not chasing phantom vibrations during load changes

- Seamless Mark VIe integration – avoids those frustrating protocol translation headaches when upgrading legacy systems

- -40°C to +85°C operating range – keeps monitoring during Arctic cold snaps or desert heatwaves where other modules tap out

- DIN rail mounting with tool-less clips – cuts installation time by nearly half during emergency replacements (from what I’ve timed onsite)

Technical specs that actually matter

| Parameter | Specification |

|---|---|

| Brand/Model | GE IS200VVIBH1CAB-W02 |

| HS Code | 8537.10.0090 (Programmable controllers for industrial use) |

| Power Requirements | 24V DC ±10%, 1.2A max (plays nice with standard turbine control cabinets) |

| Dimensions & Weight | 120 x 100 x 75mm / 380g (fits tight spaces where vibration sensors live) |

| Signal Types | 4-20mA, ±10V analog I/O; supports proximity probes & accelerometers |

Where it earns its keep

In natural gas compressor stations, it’s constantly watching for rotor imbalance during pressure surges. Power plant folks use it to catch steam turbine bearing wear before catastrophic failure – one client told me it flagged a developing issue during a routine Monday morning check that would’ve meant a $2M+ forced outage. Oil refineries lean on it for pump vibration monitoring near flare stacks where EMI would confuse lesser modules.

What procurement teams actually care about

Sure, the 365-day warranty gives peace of mind, but the real value? Compatibility with existing Mark VIe spares inventory. No need to retrain technicians – they’re already familiar with the slot configuration. One plant manager mentioned it saved them $18k in integration costs versus a third-party alternative. And when you’re racing against a forced outage clock, having it ship within a week (for in-stock units) matters more than any datasheet spec.

Installation & maintenance realities

Mount it on standard 35mm DIN rail in NEMA 1 cabinets – but keep it at least 100mm from VFDs to avoid noise coupling. I’ve seen technicians skip the grounding strap during rush installs, only to get erratic readings later. Routine check? Wipe vents quarterly (dust buildup in Gulf Coast plants is no joke) and verify calibration annually – though from field reports, drift stays under 0.5% for 18+ months in stable environments. Firmware updates? Plug in a service laptop during planned outages; takes less time than your coffee break.

Certifications that hold up under audit

CE marked for industrial machinery, UL 61010-1 compliant (no last-minute certification scrambles during plant audits), and RoHS 3-certified. GE’s standard warranty covers defects for 365 days – but in my experience, most vibration modules outlive that by 5-7 years with proper care. One caveat: warranty doesn’t cover surge damage from unshielded sensor wiring in lightning-prone areas.

Getting it to your site

We typically ship within one week if in stock (check availability – turbines don’t wait). Payment’s straightforward: 50% deposit to lock inventory, balance before shipping. All units move via FedEx/UPS/DHL with full tracking. Worst-case scenario? You’re looking at four weeks max for backorders, but I’ll keep you updated weekly – no radio silence during critical path delays.

Reviews

There are no reviews yet.