Description

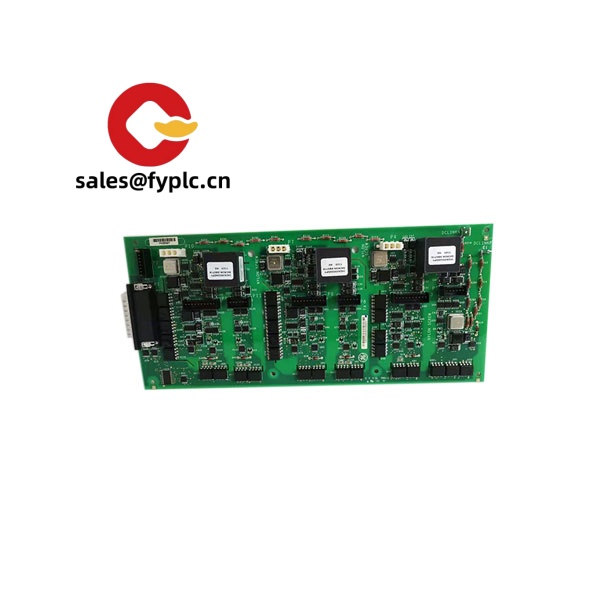

GE IS200WNPSH1ABA – I/O Network Power Supply Board for Mark VI/VIe Control Cabinets

The GE IS200WNPSH1ABA is a WNPS-series power board used in Mark VI/Mark VIe control systems to condition and distribute low-voltage DC for the I/O network side of a cabinet. From my experience, this module is typically selected to provide stable 24 VDC-class power to I/O packs, small network devices, and auxiliary control loads inside turbine and balance-of-plant panels. You might notice that it’s often specified during retrofit work, because it brings cleaner power and cabinet-friendly wiring compared with improvised power bricks.

Typical use cases include gas/steam turbine controls, wind turbine pitch or yaw cabinets, and compressor/drive panels where the Mark VI/VIe IONet and field-side electronics need a reliable, monitored power rail. One thing I appreciate is how it helps cut nuisance trips caused by power ripple—something maintenance teams mention a lot in older cabinets.

Our Order Placement Process and Guarantees

- Warranty: 365 days coverage

- Lead time: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Stabilized low-voltage DC output – Provides a clean, cabinet-ready supply for I/O packs and small network hardware, reducing ripple and brownout issues.

- Designed for Mark VI/Mark VIe cabinets – Mechanical layout and connectors suit GE control racks and panel wiring practices.

- Status and health indication – Visual indicators (LEDs) support quick checks during commissioning or fault tracing.

- Protective conditioning – Input filtering and onboard protection components help guard against electrical noise common in turbine environments.

- Revision H1ABA – Appears to be a later hardware/firmware revision for WNPS, typically favored for replacements to keep systems uniform.

- Low maintenance – In many cases, normal cabinet cleaning and periodic tighten-checks on terminals are enough to keep it running.

Technical Specifications

| Brand / Model | GE IS200WNPSH1ABA (WNPS power board for Mark VI/VIe) |

| HS Code | 8538900000 (Parts for switching/protection/control apparatus) |

| Power Requirements | Low-voltage DC input (24 VDC-class supply is typically used in Mark VI/VIe cabinets) |

| Operating Temperature | 0 to 60°C typical for cabinet-mounted GE control boards |

| Signal I/O Types | DC power distribution; onboard status indication; no process signal I/O |

| Communication Interfaces | None for data; board-level connectors for power in/out and rack interface |

| Installation Method | Panel/rack-mounted inside Mark VI/VIe control cabinets; follow GE grounding and wiring standards |

Note: Exact electrical ratings can vary by cabinet design and revision. If you share your cabinet drawing or BOM, we can validate fit and operating limits before shipment.

Related or Supporting Products

- GE IS200PDMAG1A – Power Distribution Module commonly paired in Mark VI/VIe panels for fusing and rail distribution.

- GE IS200TRLYH1B – Relay output board used for dry contact interfacing; complements WNPS-fed control circuits.

- GE IS215UCVEM06B – Mark VIe controller module; not a drop-in alternative, but often replaced in the same service window.

- GE IS200VVIBH1C – Vibration/velocity input module for rotating equipment; relies on stable low-voltage rails from cabinet supplies.

If you’re replacing earlier WNPS revisions, IS200WNPSH1ABA typically maintains mounting and wiring consistency. Differences are usually in component updates and serviceability, not in field wiring layouts.

Installation & Maintenance

- Cabinet requirements – Mount in a dry, vibration-controlled enclosure. Maintain airflow around heat-dissipating parts; avoid bundling high-noise cables with low-voltage runs.

- Grounding & wiring – Follow GE cabinet grounding; use shielded cable where specified; torque terminal screws per GE guidelines to prevent thermal loosening.

- Power-up checks – Verify input DC polarity and range before energizing. Confirm LED status and downstream rail voltage under load.

- Safety – Isolate power, wait for capacitors to discharge, and use ESD protection when handling boards.

- Routine maintenance – Quarterly dust removal with dry air, visual check of capacitors and connectors, re-torque terminals annually, and record rail voltage trends. Firmware/config revisions (if applicable) should match the site standard.

A maintenance lead at a combined-cycle plant told me their nuisance I/O resets stopped after swapping in WNPS and cleaning up the rail distribution—small change, big uptime win.

Quality & Certifications

- Certifications – Typically conforms to CE and UL when installed as part of a GE Mark VI/VIe system; RoHS status may vary by production batch.

- Manufacturer policy – GE parts are usually supported within the broader system certification; component-level compliance follows the cabinet BOM.

- Warranty – 365 days standard coverage from shipment.

Reviews

There are no reviews yet.