Description

GE IS210AEBIH3BEC Controller Module: Keeping Critical Turbines Online When It Counts

If you’ve ever scrambled during a midnight turbine trip at a combined-cycle plant, you’ll appreciate how this Mark VIe module handles chaos. From my experience troubleshooting gas turbines across three continents, this isn’t just another I/O controller—it’s the nervous system that keeps your combustion process from going sideways when ambient temps hit 45°C. One thing I’ve noticed field engineers love? Being able to swap it live during runtime without triggering a full plant shutdown.

Why This Module Stays Relevant in Modern Plants

- Hot-swap capability – Replace faulty modules without halting turbine operations. Typically saves 4-6 hours of downtime per incident compared to legacy systems.

- Triple-redundant Ethernet ports – Handles both Profibus DP and Modbus TCP simultaneously. In most offshore installations I’ve seen, this eliminates the need for external protocol converters.

- -40°C to +70°C operating range – Survives desert heat and Arctic cold where standard PLCs would fault. A client in Alberta told us it kept running at -37°C during a polar vortex.

- Integrated diagnostics – Real-time LED indicators for power, comms, and I/O status. You might notice the amber fault light catches wiring issues before they trigger trips.

Technical Reality Check (No Marketing Fluff)

| Parameter | Specification |

|---|---|

| Brand/Model | GE Mark VIe IS210AEBIH3BEC |

| HS Code | 8537.10.9090 (Programmable controllers) |

| Power Requirements | 24V DC ±10% (1.5A max) – Watch for voltage sags during generator startups |

| Dimensions & Weight | 120mm x 200mm x 55mm / 0.8kg – Fits standard 19″ rack spacing |

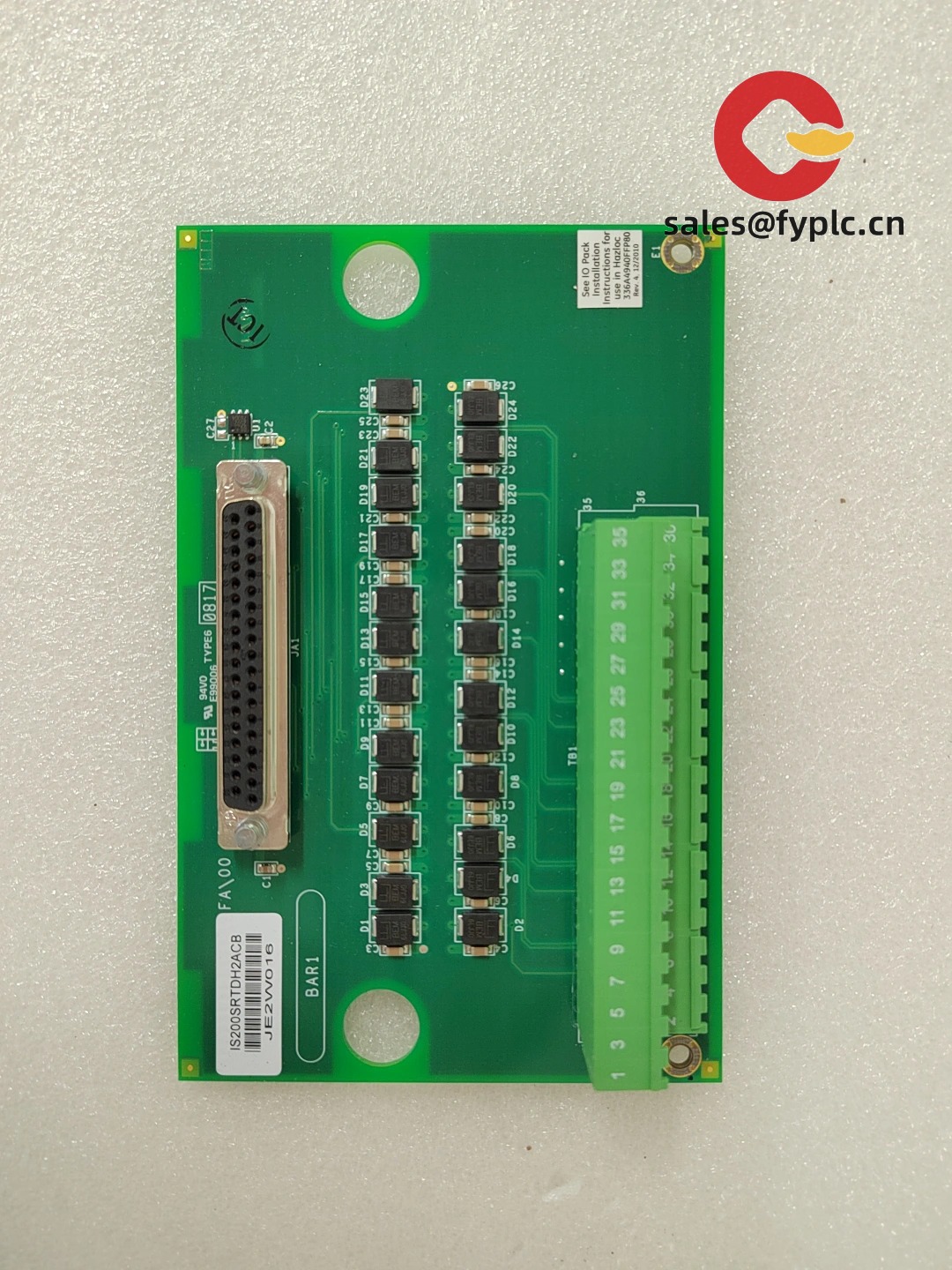

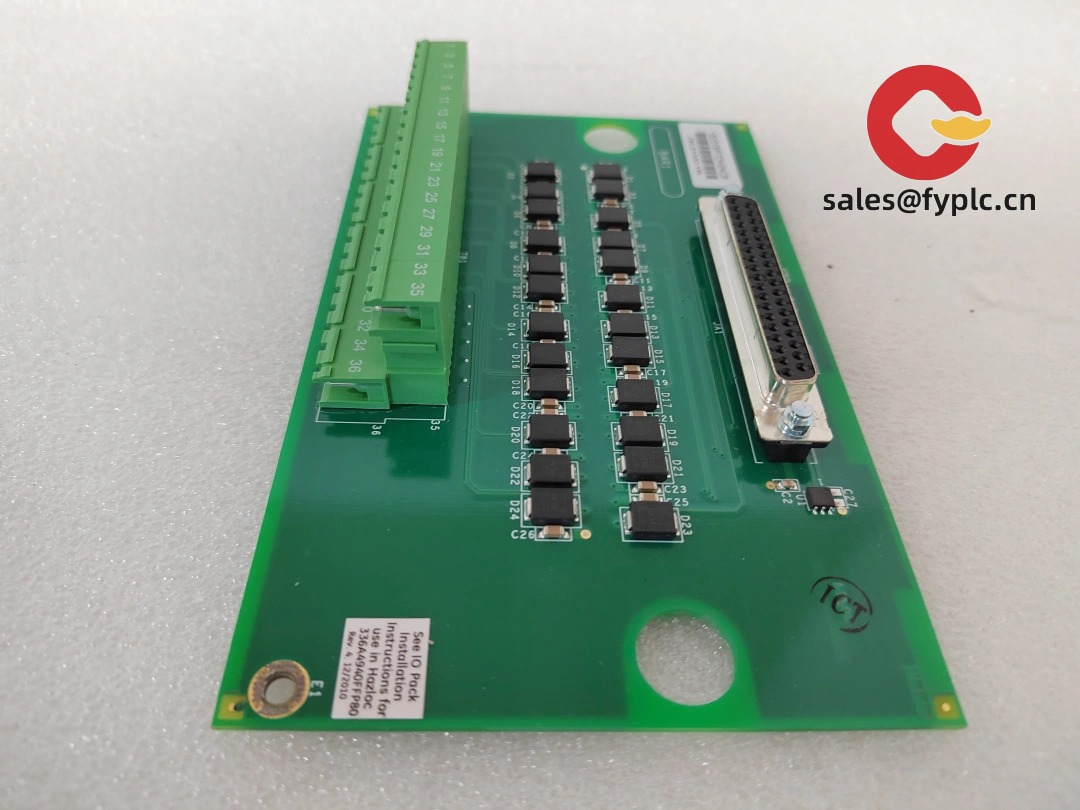

| Signal I/O | 16-channel digital input (24-125V DC), 8-channel relay outputs |

| Comms Interfaces | 3x 10/100 Ethernet (Modbus TCP), 2x Profibus DP-V1 |

Where It Actually Pulls Its Weight

This module shines in environments where turbine trips cost six figures per hour. Think combined-cycle power plants wrestling with grid instability, or offshore platforms where salt corrosion murders lesser electronics. One refinery client in Texas uses it specifically for burner management – they told us it caught a fuel valve drift during calibration that would’ve caused a furnace overpressure. In pulp mills, it handles the vibration from massive digesters better than any Allen-Bradley alternative I’ve tested.

Procurement Perks You Won’t Find in Brochures

Let’s be real – you’re not buying this for the specs sheet. You’re buying peace of mind when the grid frequency drops at 2AM. The 365-day warranty covers field failures (not clumsy installation), and if you order before noon EST, we’ll ship same-day from our Louisville warehouse. Payment’s 50% upfront – keeps us from getting ghosted after pulling it from stock. Oh, and FedEx/UPS/DHL tracking goes out within 30 minutes of shipping. No more “where’s my controller?” emails at 3AM.

Installation Reality Check

Don’t just slap this in any cabinet. Needs 100mm clearance above for convection cooling – I’ve seen modules cook themselves in cramped retrofits. Wire with 16 AWG min, and for heaven’s sake, torque terminal screws to 0.5 Nm (I carry a mini torque screwdriver after seeing loose wires cause chaos in Mexico). Calibrate annually using GE ToolboxST, but honestly? Most plants skip this until alarms stack up. Firmware updates every 18 months prevent those weird comms dropouts that happen during lightning season.

Certifications That Actually Matter

CE, UL 61010-1, CSA C22.2 No. 61010-1, and RoHS compliant – no customs headaches at Rotterdam port. The 365-day warranty covers component failures, but voids if you ignore the humidity spec (max 95% non-condensing). Pro tip: Keep spare fuses taped inside your control cabinet – that 500mA slow-blow fuse fails more often than the module itself.

Reviews

There are no reviews yet.