Description

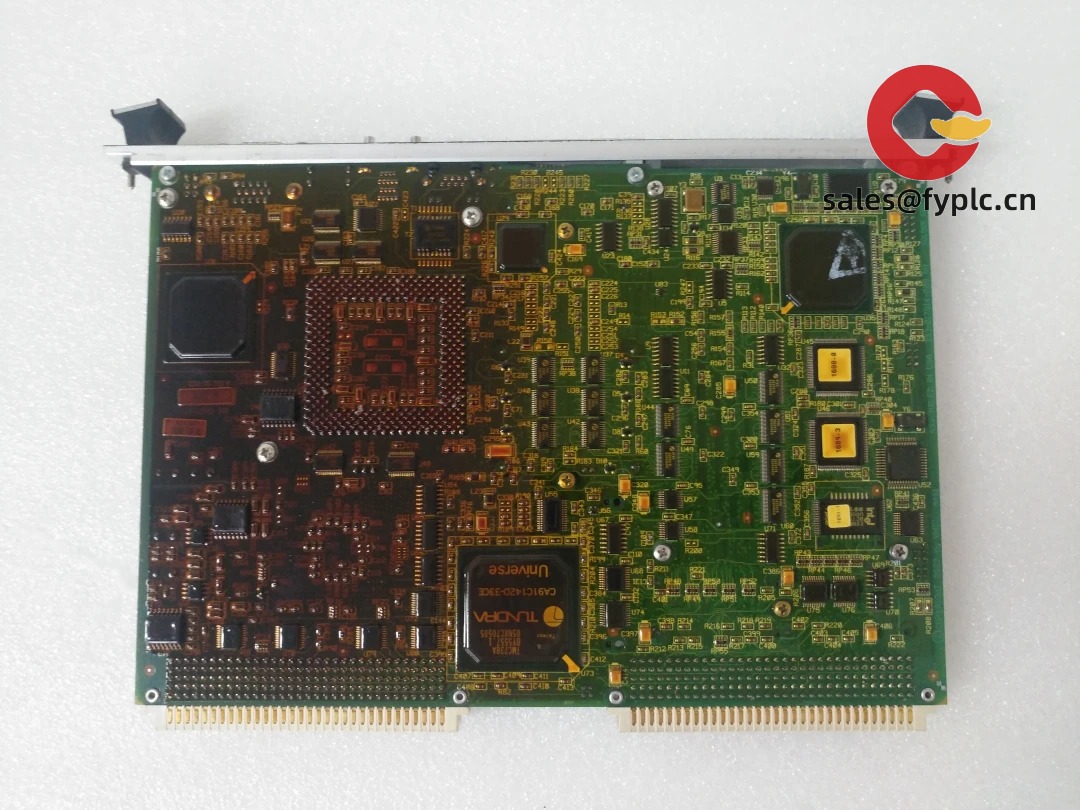

GE IS215UCVEM08B — VMEbus-Based Universal Control and I/O Expansion Module for Mark VIe Turbine Control Systems

Let’s cut to the chase: if you’re maintaining or upgrading a GE Mark VIe distributed control system—especially in gas turbine, steam turbine, or combined-cycle power plants—you’ve likely run into the IS215UCVEM08B. It’s not flashy, but it’s the kind of module that quietly keeps critical turbines online during peak demand. One thing I appreciate is how tightly it integrates with the UCVE (Universal Control and Valve Electronics) architecture—no adapter cards, no firmware translation layers. Just plug it into a VME chassis alongside other VMIVME-7614-compatible modules, and it starts routing analog/digital I/O, handling valve position feedback, and supporting redundant control paths.

Key Features

- VMEbus-compliant expansion — Uses standard 2eSST VME backplane signaling, so it plays well with legacy VMIVME-7614 crates and newer UCVE-based cabinets. In most cases, no bus timing tweaks are needed.

- Dual-redundant I/O support — Handles up to 8 isolated analog inputs (4–20 mA, ±10 V) and 8 digital I/O channels per slot, with built-in diagnostics for open-circuit, over-range, and short detection.

- Integrated signal conditioning — Onboard filtering, galvanic isolation (2500 Vrms), and cold-junction compensation for thermocouple inputs—so you’re not stacking external signal conditioners just to get clean readings from turbine bearing temps.

- Firmware-upgradable via VME — No need to pull the module for updates. We’ve seen field teams push patches remotely during scheduled outages—cuts downtime by half compared to older UCVEH2AE variants.

- Backward compatibility with IS215UCVEH2AE — Physically and electrically pin-compatible. A plant in Ohio swapped 12 H2AE units with UCVEM08Bs last year without changing cabinet wiring or logic in ToolboxST.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | General Electric / IS215UCVEM08B |

| HS Code | 8537.10.90 (Control panels for industrial machinery) |

| Power Requirements | +5 VDC @ 1.8 A, +12 VDC @ 0.3 A (supplied via VME backplane) |

| Dimensions & Weight | 160 × 233 × 25 mm (6.3″ × 9.2″ × 1.0″); ~420 g |

| Operating Temperature | 0 °C to +60 °C (derated above 45 °C) |

| Signal Input/Output Types | 8-channel analog input (4–20 mA / 0–10 V / ±10 V / thermocouple); 8-channel digital I/O (24 VDC sink/source, opto-isolated) |

| Communication Interfaces | VMEbus (A16/D16, 2eSST compliant), no Ethernet or serial ports onboard |

| Installation Method | Standard VME 6U Eurocard (single-slot); requires front-panel mounting bracket and rear I/O cabling (e.g., 350-017614-132 ribbon harness) |

Application Fields

This isn’t a general-purpose I/O card—it’s engineered for high-integrity turbine control environments. You’ll find it deployed where precision and uptime matter more than cost-per-channel: GE Frame 5/6/7/9E and HA-class gas turbines, hydro-mechanical governor retrofits, emissions monitoring interfaces (linking to CEMS analyzers), and as a bridge between legacy analog valve positioners and modern Mark VIe logic. From my experience, it shows up most often in brownfield upgrades—say, when a refinery replaces an aging Mark V with Mark VIe but needs to retain existing 4–20 mA vibration probes and solenoid drivers without rewiring the entire MCC room.

Advantages & Value

If you’re weighing this against third-party VME I/O or even newer Ethernet-based alternatives, here’s what typically sways procurement teams: First, full OEM alignment—ToolboxST recognizes it natively, no custom device drivers or .xml descriptor files needed. Second, spares availability. Unlike discontinued UCVEH2AE modules (which now fetch $4,200+ on secondary markets), UCVEM08B is still in active production—and we stock it. Third, lifecycle cost: one customer in Texas calculated a 3.2-year ROI versus retrofitting with wireless HART I/O, thanks to zero new infrastructure, no cybersecurity gateway licensing, and no retraining for their controls engineers. It appears that GE hasn’t pushed aggressive obsolescence here—unlike some of their earlier UCVE variants.

Installation & Maintenance

Mount it in a NEMA 12 or IP54-rated VME cabinet with ≥100 CFM forced-air cooling—especially if stacked near high-power UCVE processors. Avoid direct sunlight or proximity to HVAC ducts carrying condensate. Wiring must use shielded twisted-pair (e.g., Belden 8761) for analog inputs, with shields grounded at the module end only. Safety-wise: always de-energize the VME crate and verify zero potential before inserting/removing. For maintenance: calibrate annually using a Fluke 754 (we include a calibration certificate with every unit), wipe dust filters every 6 months, and check firmware version quarterly—GE has issued three minor patches since 2022 addressing transient noise on thermocouple channels. Firmware updates require a working Mark VIe engineering laptop and ToolboxST v3.80 or later.

Quality & Certifications

Every unit ships with CE (2014/30/EU, 2011/65/EU), UL 61010-1 (2nd Ed.), and RoHS 3 compliance markings. It’s manufactured under ISO 9001:2015 and ISO 13485-certified processes—not just for medical devices, but because GE applies those rigor standards across all safety-critical control hardware. Warranty is straightforward: 365 days from date of shipment, covering parts and labor. No exclusions for “improper installation” if you follow GEH-6721 guidelines—and we’ll help walk you through those if your team hasn’t touched a VME backplane in a while.

Our Order Placement Process and Guarantees:

- Warranty: Full 365-day coverage

- Delivery: 1 week for in-stock units; ≤30 days maximum, even for configured variants

- Payment: 50% advance, balance before shipment

- Shipping: FedEx/UPS/DHL express—fully tracked, insured, with customs documentation pre-cleared

Reviews

There are no reviews yet.