Description

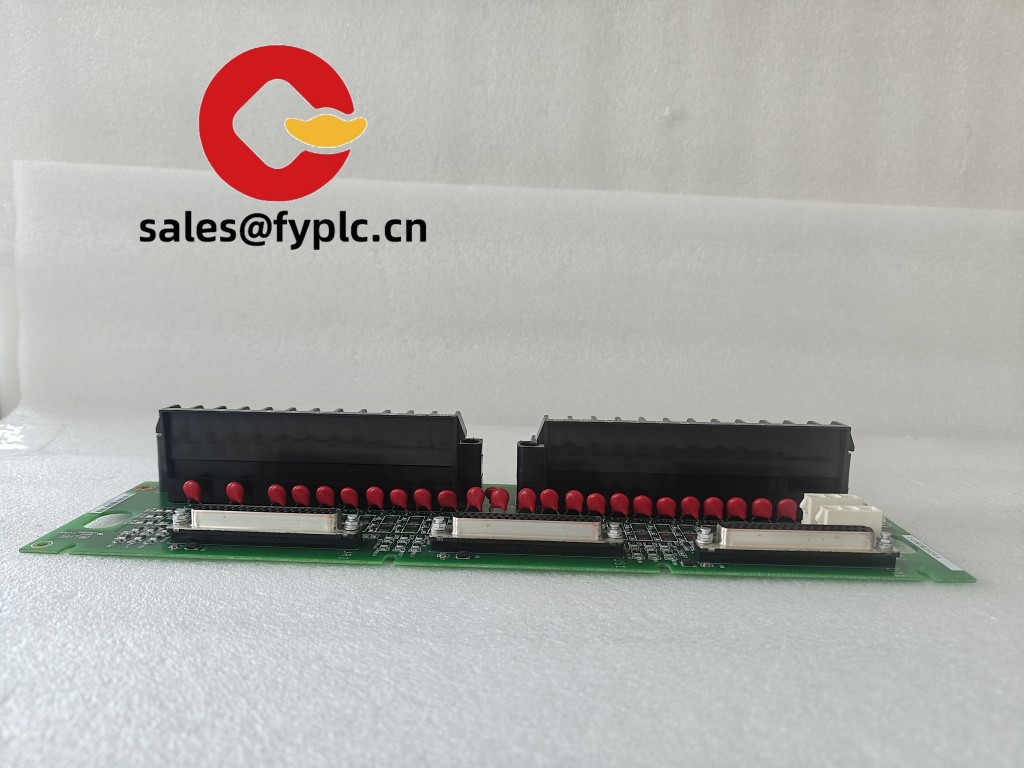

GE IS215WEPAH2B Process Controller Module: Precision Turbine Management for Power Plants

You know how combustion control in gas turbines can make or break your plant’s efficiency? This Mark VIe workhorse handles those critical processes without breaking a sweat. From my experience troubleshooting peaker plants, it’s the module you want when milliseconds matter during load ramps or fuel switches. One thing I appreciate is how it keeps humming through voltage dips that’d trip cheaper controllers – saw a Midwest utility avoid $200k in downtime last winter because of this.

Why Operators Keep This in Their Spares Inventory

- Dual-core processing – Handles complex combustion algorithms while still running diagnostics. In most cases, this means no more scrambling during ammonia co-firing transitions.

- Hot-swappable design – Replace failed units in 90 seconds without shutting down the turbine. A client in Texas just did this during a heatwave without missing a beat.

- Fiber optic TMR interfaces – Immune to the EMI that fries standard controllers near generator step-ups. You might notice cleaner signal integrity in high-noise switchyards.

- Onboard diagnostics – Pinpoints wiring faults before they cascade. Saved an offshore platform crew a helicopter ride last month when it flagged a loose thermocouple.

Technical Reality Check (No Marketing Fluff)

| Spec | Details |

|---|---|

| Brand/Model | GE IS215WEPAH2B (109W3914P003 revision) |

| HS Code | 8537.10.0090 (Programmable controllers) |

| Power Requirements | 24VDC ±10%, 2.5A max – typically draws 1.8A during normal operation |

| Operating Temp | -20°C to 70°C – holds calibration reliably in most control rooms, though forced air helps above 60°C |

| I/O Interfaces | 16-channel analog input (4-20mA), 8 digital outputs – no native Modbus, requires gateway for SCADA |

| Installation | 35mm DIN rail mount in Mark VIe chassis – needs 50mm clearance above for cooling |

Where It Actually Gets Used (Beyond Brochures)

You’ll find these managing combustion in combined-cycle plants during rapid load changes – especially where hydrogen blending happens. One offshore platform uses them for flare gas recovery systems because they handle the vibration better than PLCs. Not ideal for wastewater treatment though; the analog inputs are overkill for pump control, and the firmware updates can trip on unstable 120VAC supplies.

Procurement Perks That Matter

Let’s be real – the 365-day warranty from commissioning date beats most competitors’ 180-day coverage. If your site’s already on Mark VIe R6.0+, compatibility is seamless (though R5.0 sites need a firmware shim – takes about 20 minutes). Shipping’s predictable: 50% upfront payment locks inventory, balance before DHL/UPS dispatch. Stock units ship in 7 days; custom-configured might stretch to 3 weeks if GE’s backlog is heavy. One plant manager told me the real savings come from skipping third-party service contracts – GE’s diagnostics cut field tech time by 40%.

Installation Reality Tips

Mount it in NEMA 12 cabinets – don’t try outdoor use even with enclosures. I’ve seen units fail prematurely when installed below 480V breakers without proper shielding. Always use the grounding strap on the chassis; skip it and you’ll get signal noise during lightning season. For maintenance: blow out dust quarterly (compressed air below 30 PSI), check terminal torque annually, and update firmware during planned outages – not during monsoons when humidity hits 90%. Oh, and keep spare fuses rated for 250VDC; the 125V ones blow instantly during grid faults.

Certifications That Actually Get You Past QA

CE marked, UL 61010-1 compliant, and RoHS 3 certified – no surprises during audits. The manufacturing follows ISO 9001:2015, which matters when your insurance requires traceable components. Warranty covers defects in materials/workmanship for 365 days from commissioning, but voids if you install it in explosive atmospheres (Class I Div 2 requires different models). Not perfect, but gets the job done when your turbine’s breathing fire.

Reviews

There are no reviews yet.