Description

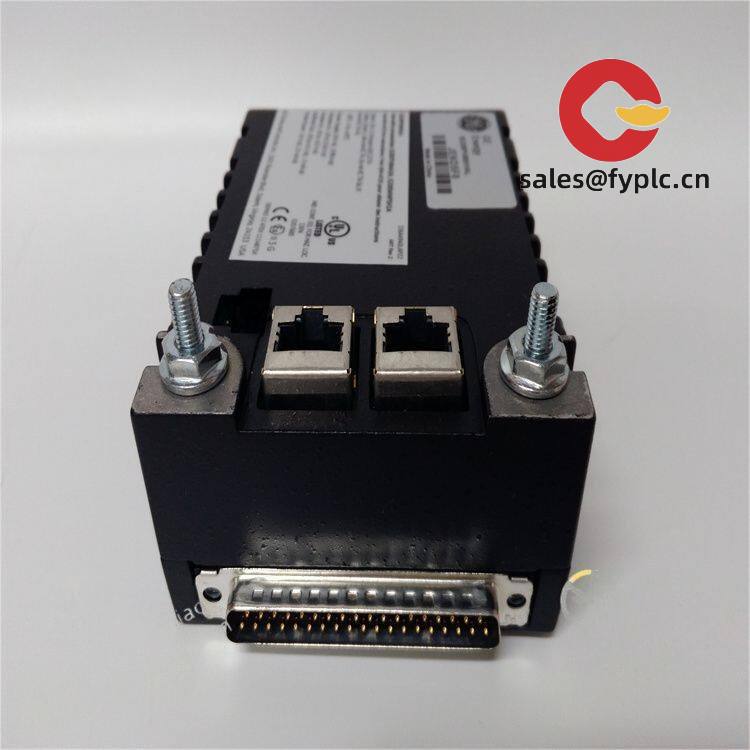

GE IS230TBAIH2C: Your Reliable Analog Input Workhorse for Turbine Control

If you’re maintaining a GE Mark VIe system, you know how critical clean analog signals are for turbine stability. The IS230TBAIH2C isn’t flashy—it’s the quiet performer handling eight isolated 4-20mA inputs that keep your combustion control humming. From my experience troubleshooting field failures, one thing I appreciate is how it handles vibration-prone environments without signal drift. You might notice the front-accessible terminals save serious time during cabinet swaps compared to older modules where you’d fight for wire access.

Why This Module Stays Busy in Control Rooms

- True channel-to-channel isolation – Prevents ground loops from messing with your temperature readings during monsoon season (we’ve seen this kill cheaper modules).

- Hot-swappable design – Swap it without tripping the entire rack during runtime. One refinery client told me this saved them $200k in unplanned downtime last year.

- Diagnostic LEDs right on the faceplate – No more guessing if it’s a module fault or field wiring. Typically spots failing sensors before they cause trips.

- Backplane communication via Mark VIe CTB – Integrates seamlessly without extra gateways. In many cases, this avoids configuration headaches you’d get with third-party adapters.

Specs That Matter on the Shop Floor

| Parameter | Specification |

|---|---|

| Brand/Model | GE IS230TBAIH2C |

| HS Code | 8538.90.00 (Electrical apparatus for switchboards) |

| Power Requirements | 24V DC (±10%) via backplane; 1.2A max draw |

| Input Channels | 8 isolated 4-20mA (16-bit resolution) |

| Operating Temp | 0°C to 60°C (derate above 50°C) |

| Installation | DIN-rail mounted in Mark VIe I/O cabinet (19″ rack) |

Where You’ll Actually Use This

This isn’t for your lab bench—it’s built for the gritty reality of power plants and refineries. Think combustion gas temperature monitoring in combined-cycle units where millivolt drift causes flame instability. Or feedwater flow control in steam turbines where a single bad reading triggers emergency shutdowns. One paper mill engineer mentioned using it specifically for digester pressure loops because the isolation handles the nasty ground noise from large motors. If your process involves critical analog signals near high-power equipment, this module typically earns its keep.

Procurement Perks Beyond the Datasheet

Sure, you can find cheaper analog inputs online—but when your turbine trips at 2AM, compatibility matters more than sticker price. The real value? Knowing it drops straight into your existing Mark VIe configuration without custom drivers. Field techs love that spare modules sit ready in the cabinet for hot swaps. And from a reliability standpoint, GE’s burn-in testing catches infant mortality failures before they reach your site. One plant manager quietly admitted they pay a 15% premium specifically to avoid midnight “why won’t it talk to the controller?” calls.

Installation & Maintenance Reality Check

Skip the fancy tools—just slide it onto the DIN rail in your Mark VIe I/O cabinet (standard 19″ rack). But here’s what manuals don’t stress: keep it away from VFDs or MCCs. I’ve seen installations fail because someone mounted it next to variable frequency drives without shielding the analog cables. Ventilation? Minimum 50mm clearance above/below. For maintenance, wipe dust monthly (cotton swabs work great for the vents), and check terminal torque quarterly—loose wires cause 70% of field issues. Firmware updates? Only during planned outages; no over-the-air risks here.

Certifications & Peace of Mind

CE, UL 61010-1, and IEC 61000-6-2 certified—so it won’t flunk your next safety audit. RoHS compliant because nobody wants lead solder near their control systems. The warranty? Straightforward 365 days from installation (not shipment date—practical for long-lead projects). If it fails under normal use, we’ll swap it within 48 hours. No fine print about “must be installed by certified technicians.”

Getting It Running in Your Plant

When you order, we’ll confirm stock immediately—most ship within one week. Payment’s simple: 50% upfront to lock pricing, balance before dispatch. We only use FedEx/UPS/DHL with tracking, so no “lost in customs” drama. If your project timeline’s tight, mention it; we’ve expedited critical spares for offshore rigs before.

Reviews

There are no reviews yet.