Description

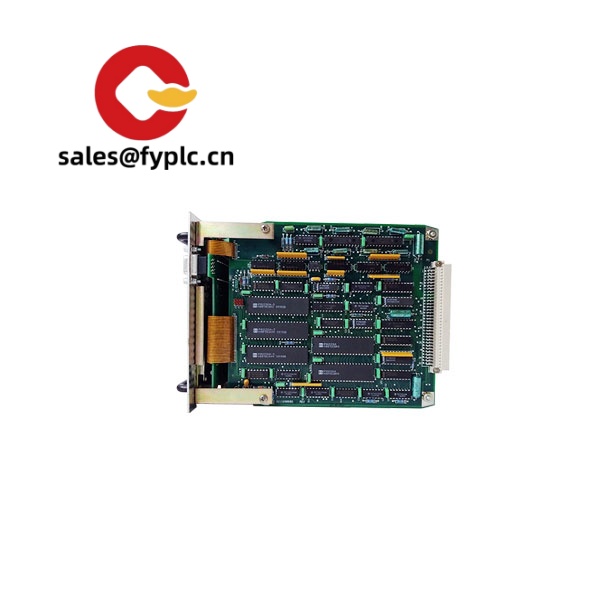

GE MMI301 – Operator Interface for Reliable Machine Control and Clear On‑line Monitoring

The GE MMI301 is typically used as a man–machine interface in GE automation environments, giving operators a straightforward window into PLC data, alarms, and process commands. From my experience, teams deploy it on legacy and mid-life production lines where stability matters more than bells and whistles. You might notice that it focuses on dependable communications and simple, repeatable operation—ideal for packaging, water treatment skids, or discrete assembly cells that run 24/7.

In many cases, the MMI301 is panel-mounted, powered by 24 VDC, and communicates with GE controllers over serial or Ethernet. Whether you’re supervising setpoints, acknowledging alarms, or walking through a startup checklist, it keeps the operator flow familiar, which usually shortens changeover time and cuts training effort. One thing I appreciate is that replacements are straightforward: swap the unit, load the project, check comms, and you’re back online fast.

Our Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery: FedEx, UPS, DHL

- Each unit is function-checked prior to shipment and packed for industrial transit

Key Features

- Operator-focused interface – Designed for routine operations: start/stop, setpoint adjustment, alarm review, and basic diagnostics.

- Reliable 24 VDC operation – Typically runs on 24 VDC, supporting stable cabinet integration with standard industrial power supplies.

- Industrial communications – Commonly supports RS‑232/RS‑485 and 10/100 Ethernet for connecting to GE PLCs; protocols like SNP/SRTP or Modbus are often used on these deployments.

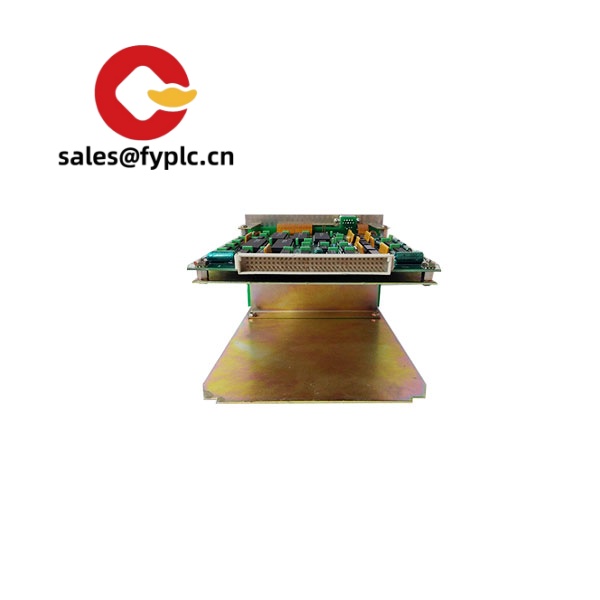

- Panel-mount form factor – Fits control panels with a simple cutout and gasket; maintenance can replace the unit without reworking the cabinet.

- Stable in plant conditions – Built for control rooms and shop-floor enclosures where 0–50 °C operation is standard practice.

- Fast changeover – From my experience, restoring a backed-up project to a replacement unit typically takes minutes, reducing downtime risk.

Technical Specifications

| Brand / Model | GE MMI301 |

| HS Code | 8537.10 (Boards/panels for electric control, industrial use) |

| Power Requirements | 24 VDC nominal; typical consumption < 15 W (varies by revision) |

| Operating Temperature | 0 to 50 °C (indoor panel enclosure) |

| Communication Interfaces | RS‑232/RS‑485; 10/100Base‑T Ethernet (availability can depend on unit options) |

| Signal I/O Types | No onboard discrete/analog I/O; data via PLC communication |

| Installation Method | Panel‑mount with front bezel gasket; rear terminal block for power and comms |

Field note from a maintenance lead: “We swapped an aging GE MMI301 on a 90‑30 line and had production back in under an hour—backup, download, quick comms check, done.” Results can vary, but that’s fairly typical when the project file is ready.

Related or Supporting Products

- GE QuickPanel+ series (e.g., IC754 variants) – Newer HMI platforms with higher resolution and faster processors; suitable when you want a modern replacement with Ethernet-first connectivity.

- GE VersaMax PLC (IC200 series) – Often paired on compact machines; the MMI301 commonly communicates via serial or Ethernet to these controllers.

- GE PACSystems RX3i (IC695 series) – For larger systems where you need more advanced logic, SRTP/Modbus TCP links to an HMI are standard practice.

- Pro-face GP4000 or Red Lion G3 HMIs – In many cases used as alternates where protocol compatibility is required beyond GE-native protocols.

- 24 VDC DIN-rail power supplies (industrial grade) – A stable 24 VDC source reduces display browning and random resets over time.

Installation & Maintenance

- Panel & environment – Install in a sealed control cabinet meeting IP/UL enclosure standards; allow ventilation or passive airflow to keep internal temps within 0–50 °C.

- Power & grounding – Use a regulated 24 VDC SELV source. Bond the HMI ground to the panel ground bar; avoid sharing power with inductive loads without filtering.

- Wiring practices – Shielded twisted pair for RS‑485; keep comms separate from VFD motor leads. Terminate serial buses properly; set unique node addresses.

- Network setup – For Ethernet, fix IP addresses and document them on the inside of the panel door. Disable unused services where possible.

- Project backups – Keep the runtime/project file archived offsite. After any change, save the version and checksum so a replacement MMI301 can be deployed quickly.

- Routine care – Periodically clean the bezel with a lint-free cloth; check connectors for looseness, and review alarm logs for recurring faults. Firmware updates should be planned during scheduled downtime.

- ESD & safety – Power down and discharge before removal. Observe ESD precautions to protect internal electronics.

Quality & Certifications

- Typically complies with CE; UL/cUL listings are common for GE operator interfaces

- RoHS compliance in many cases; exact status can depend on the unit’s production revision

- Manufacturer-grade quality control; each unit is inspected and function-tested before shipping

- Warranty: 365 days from delivery

If you’re confirming compatibility, share your controller type (e.g., VersaMax, Series 90‑30, RX3i), desired protocol, and power/space constraints. We can check comms options and advise the fastest drop‑in path—it seems to save time during planned shutdowns.

Reviews

There are no reviews yet.