Description

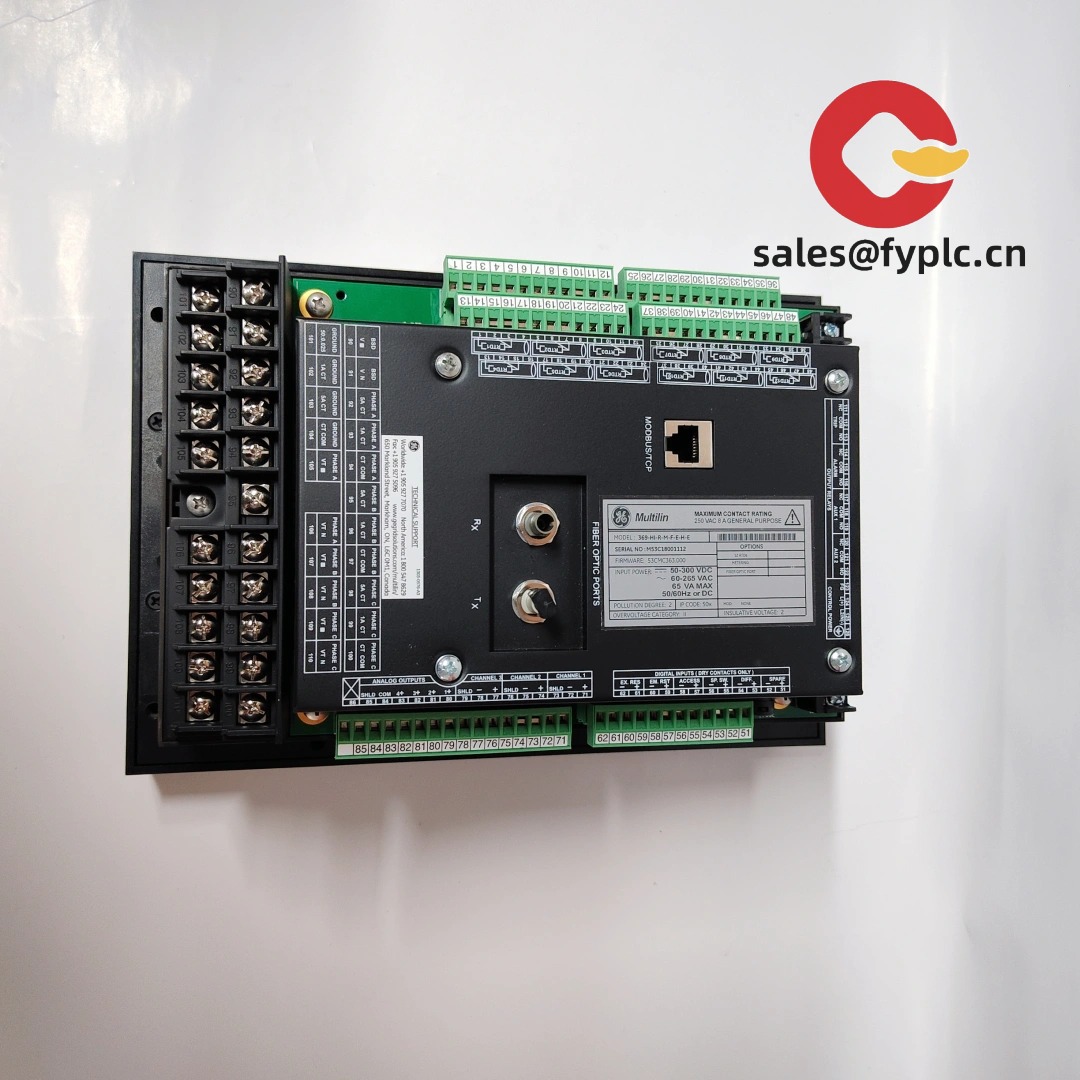

GE Multilin 369-H1-R-M-F-E-H-E – Motor Management Relay for Protection, Control and Monitoring

The GE Multilin 369 series is a workhorse motor management relay for medium/large AC motors. The 369-H1-R-M-F-E-H-E build adds a mix of popular options that, in many cases, cover protection (thermal/overload, stall/jam, unbalance, ground fault), metering, event logs, and communications for plant integration. From my experience, teams choose this model when they want a direct retrofit into an existing MCC cubicle or control panel with minimal rework—wire the CTs/PTs and I/O, land the comms, and you’re back online with clear front‑panel diagnostics.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in‑stock; no more than one month at the latest

- Payment: 50% advance payment, full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

- Pre‑shipment: visual/label verification and basic functional checks; ESD‑safe, shock‑resistant packing

Key Features

- Comprehensive motor protection – Overload thermal model, jam/stall, phase loss/unbalance, ground fault, starts/hour and start inhibit logic.

- RTD support (option‑dependent) – Up to multiple RTDs for stator/bearing temperature biasing of the thermal model, which typically reduces nuisance trips.

- Integrated metering – True RMS current, voltage (if VT wired), power/energy, demand, and runtime counters for better maintenance planning.

- Event and waveform records – Time‑stamped trips/alarms and sequence of events help pinpoint root causes after a stop.

- Communications for SCADA/DCS – RS‑485 Modbus as standard on many builds; Ethernet/Modbus TCP available on variants for easy tag mapping.

- Panel‑mount, service‑friendly – Clear HMI with status LEDs; draw‑out/serviceable case style makes swaps predictable during short outages.

- Control I/O – Programmable digital inputs and Form‑C outputs for trips, alarms, permissives, and remote reset.

Technical Specifications

| Brand / Model | GE Multilin 369-H1-R-M-F-E-H-E |

| Function | Motor management/protection relay for AC motors (MCC/panel mounting) |

| HS Code (reference) | 8536.49 – Electrical relays (final classification may vary by country) |

| Power Requirements | Auxiliary supply, universal range on many builds (typically 90–264 VAC or 90–300 VDC); variant‑dependent |

| Signal I/O Types | 3‑phase CT inputs (1 A/5 A), optional ground CT; digital inputs; Form‑C relay outputs; optional RTD inputs; optional 4–20 mA out (variant‑dependent) |

| Communication Interfaces | RS‑485 Modbus RTU; Ethernet/Modbus TCP available on some E‑options (confirm by build code) |

| Operating Temperature | Typically 0…+60 °C (panel‑mounted; non‑condensing) |

| Installation Method | Flush/panel mounting in MCC door or enclosure; wiring per GE Multilin outline & terminal drawings |

Application Fields

Typical motors protected by the 369 in continuous‑duty service:

- Pumps, fans, and blowers – thermal model with RTD bias helps avoid premature trips on hot days.

- Compressors and crushers – jam/stall and unbalance protection with fast, decisive tripping.

- Conveyors and mills – starts/hour limit, acceleration time, and underload detection for broken belts.

- Process MCCs – clean SCADA integration via Modbus for status, metering, and SOE records.

A maintenance lead told me last quarter, “We swapped in the 369 build, matched the CT ratio and RTDs, and the motor came up with better alarming than before.” That’s been a common outcome when the wiring is tidy and the comms map is planned.

Advantages & Value

- Reliability – Proven relay platform for 24/7 plants; stable tripping and clear diagnostics.

- Compatibility – Easy retrofit into MCC doors/panels; Modbus comms simplify DCS/PLC integration.

- Lifecycle savings – Extends asset life by preventing thermal overload and mechanical jams.

- Support – Help available on build‑code confirmation, CT/VT selection, and parameter templates.

- Delivery assurance – Stock‑based turnaround and practical lead times to meet outage windows.

Installation & Maintenance

- Panel mounting: Follow the GE outline cutout; ensure gasket/door rigidity to avoid HMI stress.

- CT & ground wiring: Use dedicated CT circuits; verify polarity and burden; ground CT where specified.

- RTDs & analog: Land shielded RTD cables; keep away from VFD leads; confirm sensor type in settings.

- Comms: RS‑485 twisted‑pair with proper termination/bias; for Ethernet variants, segregate from high‑noise cables and bond shields 360°.

- Parameterization: Set motor nameplate, CT/VT ratios, thermal model, starts/hour, trip classes; validate with a dry‑run.

- Routine care: Periodic dust cleaning, terminal re‑torque, SOE review, and saving a config backup with the panel docs.

Quality & Certifications

- Built to GE Multilin industrial standards, typically aligned with ISO 9001 quality systems.

- CE compliance for EMC/Low Voltage on relevant variants; many builds are UL/cUL Listed/Recognized.

- RoHS compliance depends on production variant; we can verify by part/serial.

- Warranty: 365 days repair/replace coverage from delivery.

Reviews

There are no reviews yet.