Description

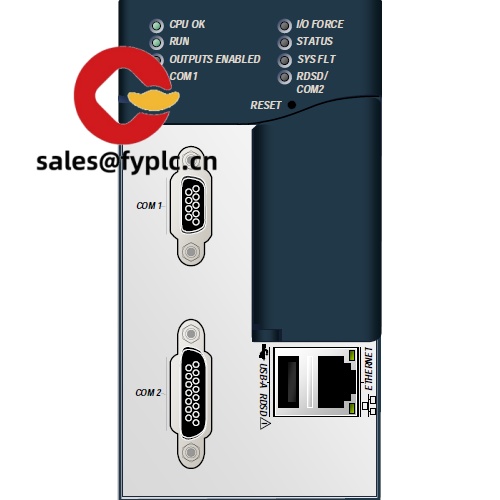

GE PACSystems RX3i IC695CRU320-EJ – Redundancy‑Capable CPU for High‑Availability Control

The GE IC695CRU320-EJ is a redundancy‑ready CPU for the PACSystems RX3i platform, designed for plants that simply can’t afford downtime. When paired as a redundant CPU set and synchronized via an RMX module, it delivers hot‑standby operation with a fast, predictable switchover. From my experience, this model fits best in water/wastewater, power and utilities, oil & gas, and batch process lines where continuity is critical and diagnostics need to be straightforward. The “-EJ” suffix indicates a later hardware/firmware revision; in most cases it preserves the same core functionality while improving lifecycle support.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in‑stock items; no more than one month at the latest

- Payment terms: 50% advance payment; full payment before delivery

- Express delivery options: FedEx, UPS, DHL

Key Features

- Redundancy‑ready CPU – Works as a primary/secondary pair for hot‑standby control when used with the RX3i redundancy toolkit (typically with an IC695RMX module for state synchronization).

- Deterministic control performance – Consistent scan times and fast task execution for motion, batch, and continuous process logic on the RX3i backplane.

- Seamless RX3i ecosystem compatibility – Supports the full range of IC695 I/O and specialty modules; you can scale from a few points to large racks without changing the CPU family.

- Flexible networking – Ethernet or PROFINET is added via RX3i modules (e.g., IC695ETM001 or IC695PNC001), so you can tailor communications to the plant network standards.

- Robust diagnostics – Clear CPU and redundancy status LEDs and detailed fault reporting in Proficy Machine Edition make troubleshooting quick.

- Industrial temperature range – Designed for typical control cabinet environments, with reliable operation in most plant conditions.

- Field‑proven in uptime‑critical systems – You might notice that many water plants and power facilities prefer CRU‑class CPUs for smooth, bumpless transfers during maintenance or failover.

Technical Specifications

| Brand / Model | GE PACSystems RX3i / IC695CRU320-EJ |

| Product Type | Redundancy‑capable CPU module for RX3i |

| HS Code | 8537.10 (Programmable controllers) |

| Power Requirements | Powered from RX3i backplane via IC695 power supply; no external field power to CPU |

| Dimensions & Weight | Standard single‑slot RX3i format; approx. 130 × 36 × 120 mm; ~0.3 kg (typical) |

| Operating Temperature | 0 to 60 °C (32 to 140 °F), 5–95% RH non‑condensing (typical for RX3i) |

| Signal I/O Types | No onboard field I/O; uses RX3i I/O modules for discrete/analog/specialty signals |

| Communication Interfaces | Service/diagnostic port on front; plant networking via add‑on modules (e.g., IC695ETM001 Ethernet, IC695PNC001 PROFINET). Redundancy sync typically via IC695RMX module. |

| Installation Method | Mounts in RX3i Universal Backplane (IC695CHSxxx); panel‑mounted cabinet installation |

Related or Supporting Products

- IC695RMX128 – Redundancy Memory Xchange for CPU‑to‑CPU state synchronization (essential for hot‑standby systems).

- IC695ETM001 – Ethernet module for plant network connectivity and SCADA integration.

- IC695PNC001 – PROFINET Controller for distributed I/O architectures.

- IC695CHS012 / IC695CHS016 – RX3i 12‑slot / 16‑slot backplanes.

- IC695PSA040 (AC) / IC695PSD040 (DC) – RX3i power supplies sized for typical CPU + I/O loads.

- IC695CPU320 – Similar non‑redundant CPU for standalone applications (simpler and usually lower cost).

- IC695CPE330 – Newer CPU with embedded Ethernet (not redundancy‑class; migration may require configuration changes).

A systems integrator in wastewater told us they chose the CRU variant after a maintenance cutover test showed switchover didn’t trip downstream drives—exactly the kind of result you want when the process must keep running.

Installation & Maintenance

- Cabinet & environment – Install in an IP‑rated, ventilated control cabinet. Keep within 0–60 °C and non‑condensing humidity. Allow space for airflow around the CPU.

- Backplane & power – Use an RX3i IC695CHS backplane with an appropriately sized IC695 power supply. Ground the panel and backplane per GE wiring practices.

- Networking – Add Ethernet/PROFINET modules as needed. Use shielded cables in noisy areas; separate power and comms wiring where practical.

- Redundancy pairing – For hot‑standby, match hardware revisions and firmware between the two IC695CRU320 units, and configure the RMX link correctly. From my experience, a full proof‑of‑concept switchover test before go‑live pays off.

- Firmware & backups – Keep firmware aligned with the project toolchain (Proficy Machine Edition). Back up logic and CPU parameters after each change.

- Routine care – Inspect connectors, clean dust with dry air, and check the CPU’s battery status periodically if battery‑backed retention is used.

Quality & Certifications

- CE, UL/cUL marking (typical for RX3i platform)

- RoHS compliant components

- Manufactured under ISO 9001 quality systems

- Warranty: 365 days from delivery

Reviews

There are no reviews yet.