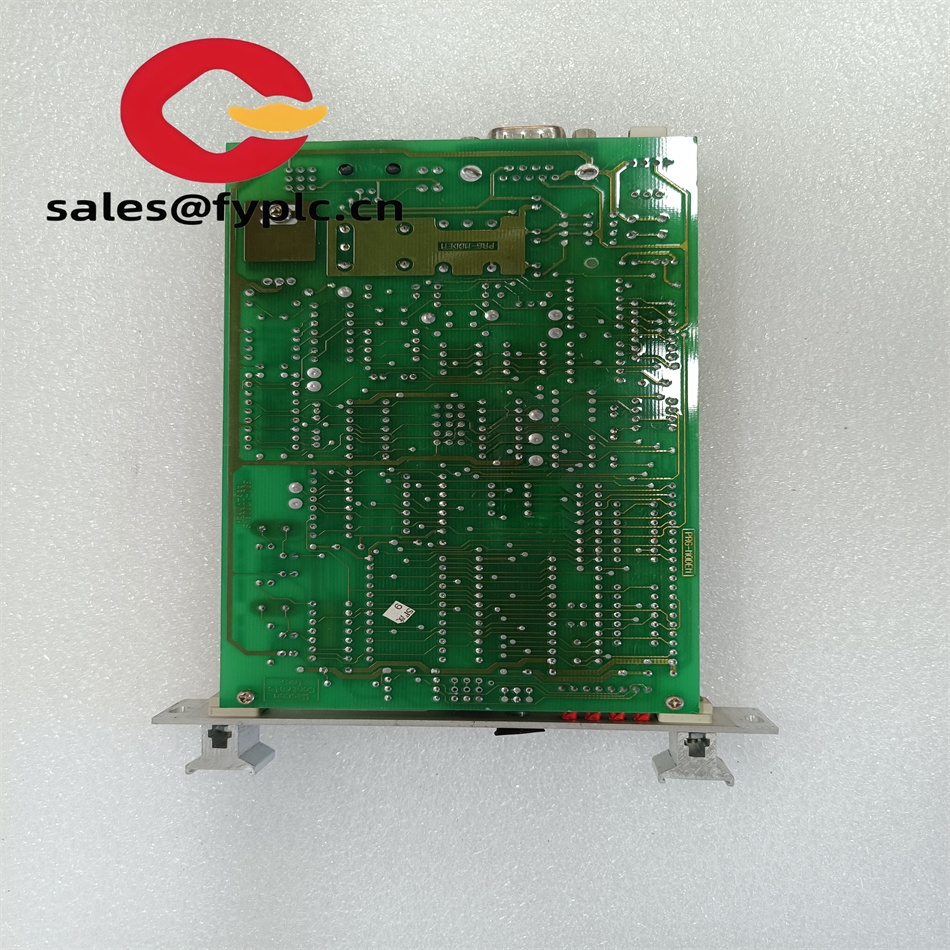

GE PRG-MODEM Communication Adjustment Module

Tel: +86 17350880093

Whatsapp: 17350880093

E-mail : sales@fyplc.com

Zhangzhou Fengyun Electrical Equipment Co.LTD

Categories: GE

Need help?

Email: sales@fyplc.cn

Tel/WhatsApp: +86 173 5088 0093

Description

GE PRG-MODEM Communication Adjustment Module

In the intricate world of industrial automation, the GE PRG-MODEM stands as a crucial player, enabling seamless communication and data transfer across diverse systems. This advanced communication handler from General Electric is meticulously engineered to meet the rigorous demands of modern industrial control setups. Whether it’s a Distributed Control System (DCS), Supervisory Control and Data Acquisition (SCADA) system, or other complex automation networks, the GE PRG-MODEM ensures that data flows smoothly, commands are executed accurately, and operations run with optimal efficiency. It’s designed to be the bridge that connects various components within an industrial ecosystem, facilitating real-time monitoring and control, which is essential for maintaining productivity and safety in industrial environments.

| Label | Specification |

|---|---|

| Model Number | PRG-MODEM |

| Brand | General Electric |

| Type | Modem Module |

| Input Voltage | 9 – 24V DC |

| Operating Temp | -20°C to 70°C |

| Communication Method | Serial (RS-232, RS-485), Ethernet, Wireless |

| Mounting | DIN Rail, Panel Mount |

| Weight | [X] kg |

| Certifications | CE, UL |

| Dimensions | [Length] x [Width] x [Height] mm |

| IP Rating | IP20 |

| Protocols Supported | Modbus, DNP3, IEC 61850 |

The GE PRG-MODEM has been engineered to deliver outstanding performance in the most challenging industrial scenarios. Its high-speed data transfer capabilities ensure that critical information is relayed instantaneously, reducing latency and enabling swift responses to changing conditions. Resilience is another key strength; built with robust components, it can withstand harsh environmental factors such as electrical interference, vibrations, and temperature fluctuations. Interoperability is also a highlight, as the GE PRG-MODEM is designed to work harmoniously with a wide range of industrial devices and systems. Operators benefit from its user-friendly design, which simplifies integration and configuration. The unit’s build quality is top-notch, with a durable enclosure that protects internal components, ensuring long-term reliability and minimizing downtime.

In industrial use cases, the GE PRG-MODEM truly shines. In the power generation industry, it’s deployed to monitor and control electrical grids, ensuring stable power distribution. In manufacturing plants, it plays a vital role in SCADA systems, enabling operators to track production processes, manage resources, and detect and resolve issues promptly. For example, in a large-scale chemical plant, the GE PRG-MODEM can be used to connect sensors and actuators across different production lines, providing real-time data on chemical levels, temperatures, and pressures. This allows for precise control, reducing the risk of accidents and improving overall process reliability. In the oil and gas sector, it supports remote monitoring of pipelines, ensuring the safe and efficient transportation of resources.

Several models are closely related to the GE PRG-MODEM. GE PRG-MODEM – Plus offers enhanced security features, making it ideal for applications where data confidentiality is paramount. GE Mini PRG-MODEM is a compact alternative, perfect for space-constrained environments without compromising on performance. GE PRG-MODEM – Industrial Pro has additional communication ports, allowing for greater connectivity in complex industrial setups. GE PRG-MODEM – High-Speed is designed for applications that require extremely fast data transfer rates, such as high-frequency trading in power markets. GE PRG-MODEM – Green focuses on energy efficiency, reducing power consumption while maintaining reliable communication.

When it comes to setting up the GE PRG-MODEM, careful attention to detail is required. For physical installation, ensure proper grounding to prevent electrical surges from damaging the unit. If using the DIN rail or panel mount option, make sure it’s securely fastened and there’s sufficient airflow around it to prevent overheating. During the initial configuration, follow the provided documentation carefully to set up communication protocols and network settings correctly. For long-term operation, regular inspections are recommended. Check for any signs of physical damage, loose connections, or abnormal behavior. Monitor the unit’s performance metrics, such as data transfer rates and error rates, to identify potential issues early. If any problems arise, the GE PRG-MODEM has built-in diagnostic tools that can help pinpoint the root cause.

General Electric stands firmly behind the GE PRG-MODEM, offering comprehensive warranty and support coverage. The company’s confidence in the product’s durability is evident in its long-term warranty, which provides customers with peace of mind. With a global support network, users can access technical assistance whenever needed, ensuring minimal disruption to their operations. Extensive documentation is available, covering everything from installation guides to troubleshooting tips, making it easier for engineers and technicians to work with the GE PRG-MODEM. Additionally, remote support options are available, allowing experts to diagnose and resolve issues without the need for on-site visits in many cases. This commitment to customer assurance and long-term reliability makes the GE PRG-MODEM a trusted choice for industrial automation applications.

For more information, please click below to learn more:

Be the first to review “GE PRG-MODEM Communication Adjustment Module” Cancel reply

Reviews

There are no reviews yet.