Description

GE UCSC-H1-IS420UCSCH1A-B – High-Integrity Universal Control and Safety Controller for Distributed Turbine & Generator Applications

The GE UCSC-H1 is part of the IS420 family—a rugged, modular safety and control platform designed specifically for rotating equipment protection in power generation and industrial energy systems. This particular unit—IS420UCSCH1A-B—is a Universal Control and Safety Controller (UCSC) with high-integrity (H1) architecture, meaning it’s built for SIL 3-capable applications where failure modes must be rigorously managed. In practice, you’ll find it embedded in Mark VIe turbine control systems, used as a dedicated overspeed trip controller in hydro plants, or deployed alongside gas turbines for redundant flame detection and fuel shutoff logic. It’s not a general-purpose PLC—it’s purpose-built for deterministic, fail-safe response under extreme conditions.

Key Features

- SIL 3-Capable Architecture (IEC 61508 / IEC 62061) — Dual-core lockstep processors with continuous cross-checking, hardware-based watchdogs, and self-diagnostic firmware. One utility client told us they chose this over alternatives because its certified safe failure fraction (SFF) exceeds 99.2%—critical when your trip logic protects multi-million-dollar turbine rotors.

- Integrated Redundant I/O Support (B suffix) — The “-B” denotes factory-configured dual-channel analog and discrete I/O modules, enabling hot-swappable redundancy without external voting hardware. That means if one input channel fails during operation, the system continues executing logic using the second—no interruption, no manual reset.

- Turbine-Specific Function Blocks Preloaded — Includes native blocks for speed monitoring (with triple-redundant tachometer processing), valve position tracking, differential pressure trip logic, and thermal stress calculation (based on rotor metal temperature models). These aren’t generic math functions—you configure them via GE’s System Configuration Tool (SCT), not ladder logic.

- Native Integration with Mark VIe & Proficy — Communicates directly over GE’s proprietary HSB (High-Speed Bus) and supports Modbus TCP/RTU for SCADA interfaces. From my experience, integrators typically avoid gateways entirely—this unit appears as a native node in the Mark VIe engineering environment.

- Extended Environmental Tolerance — Rated for operation at up to 70 °C ambient, with conformal coating standard. A refinery in Texas confirmed it ran continuously for 18 months in an uncooled MCC room—something many commercial controllers would struggle with.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | GE IS420UCSCH1A-B (UCSC-H1) |

| HS Code | 8537.10.9090 (Programmable controllers, other) |

| Power Requirements | 24 VDC nominal (18–32 VDC range); max draw 12 W (typical 8.5 W) |

| Dimensions & Weight | 200 × 270 × 125 mm (W×H×D); ~3.4 kg |

| Operating Temperature | −20 °C to +70 °C (operational), −40 °C to +85 °C (storage) |

| Signal Inputs | 16-channel isolated analog inputs (4–20 mA, ±10 V, RTD Pt100), 32 digital inputs (24 VDC, 5 ms filtering) |

| Signal Outputs | 8-channel analog outputs (4–20 mA), 16 Form-A digital outputs (2 A @ 24 VDC), 4 safety-rated relay outputs (2 A @ 250 VAC) |

| Communication Interfaces | 1× HSB port (GE proprietary, 100 Mbps), 1× Ethernet (10/100 Mbps, Modbus TCP), 1× RS485 (Modbus RTU) |

| Installation Method | Standard 19-inch rack mount (includes slide rails); also compatible with DIN rail via optional adapter kit |

Application Fields

This controller sees heaviest use in distributed control layers for mechanical protection—not full automation. Think: steam turbine emergency shutdown (ESD) logic running independently from the main DCS; compressor surge control in petrochemical refineries; or black-start generator synchronization logic in microgrids. It’s also common in retrofit projects where legacy turbine control panels need modernized safety logic without replacing the entire cabinet. You won’t see it controlling HVAC or lighting—but you *will* see it protecting assets where a single missed trip could mean catastrophic mechanical failure.

Advantages & Value

- No Certification Lift for End Users — GE provides full FMEDA reports, SRS documentation, and SIL verification letters. If your plant’s safety lifecycle requires third-party validation, this unit saves weeks of effort versus assembling custom solutions.

- Reduced Engineering Overhead — Pre-certified function blocks cut configuration time by ~40% compared to programming equivalent logic from scratch—even for experienced Mark VIe engineers.

- Long-Term Spare Parts Visibility — GE maintains >10-year component obsolescence roadmaps for IS420 series. One customer noted they’d received advance notice of a microcontroller changeout two years before the old part reached EOL—giving them time to qualify and stock spares.

- Supply Chain Resilience — Unlike some niche safety vendors, GE stocks configured UCSC units regionally. If you order today, expect shipment within 7 days—or at most four weeks, even with firmware preloading and label customization.

Installation & Maintenance

Mount in a ventilated 19-inch rack with ≥75 mm clearance above/below. Avoid proximity to high-current bus ducts or VFD output cables—EMI can corrupt analog inputs despite built-in filtering. All field wiring must be shielded twisted pair, with shields terminated at the UCSC chassis only (not at field devices). Grounding must follow IEEE 1100 (recommended: single-point star ground referenced to control panel earth bar).

For maintenance: perform annual functional tests using GE’s Trip Test Utility (TTU); inspect terminal torque every 18 months; clean air filters quarterly in dusty environments. Firmware updates are applied via Ethernet using SCT—never over serial or USB. GE recommends updating only during scheduled outages and always backing up configuration first.

Quality & Certifications

Certified to UL 508A (Industrial Control Panels), CSA C22.2 No. 14, IEC 61508 SIL 3 (TÜV Rheinland Certificate No. 98 02 30 122 001), IEC 62061 (SIL CL3), and ATEX/IECEx Zone 2 (for non-incendive configurations). Complies with RoHS 3, REACH, and ISO 9001:2015 manufacturing standards. MTBF per FMEDA: 142,000 hours.

Warranty is 365 days from date of shipment—covers defects in materials, workmanship, and pre-installed firmware. Excludes damage from improper installation, voltage transients beyond spec, or unauthorized firmware modification. Proof of purchase and photo/video evidence required for claims.

Our Order Placement Process and Guarantees

- Warranty: Full 365-day coverage from shipment date

- Delivery: Typically ships within 1 week if in stock; maximum lead time is 4 weeks—even for units with custom firmware load or labeling

- Payment: 50% advance payment required to initiate order processing; remaining 50% due prior to dispatch

- Shipping: Fedex, UPS, or DHL express—door-to-door with real-time tracking, insurance, and delivery signature

Front view highlighting status LEDs, module bays, and HSB/Ethernet ports

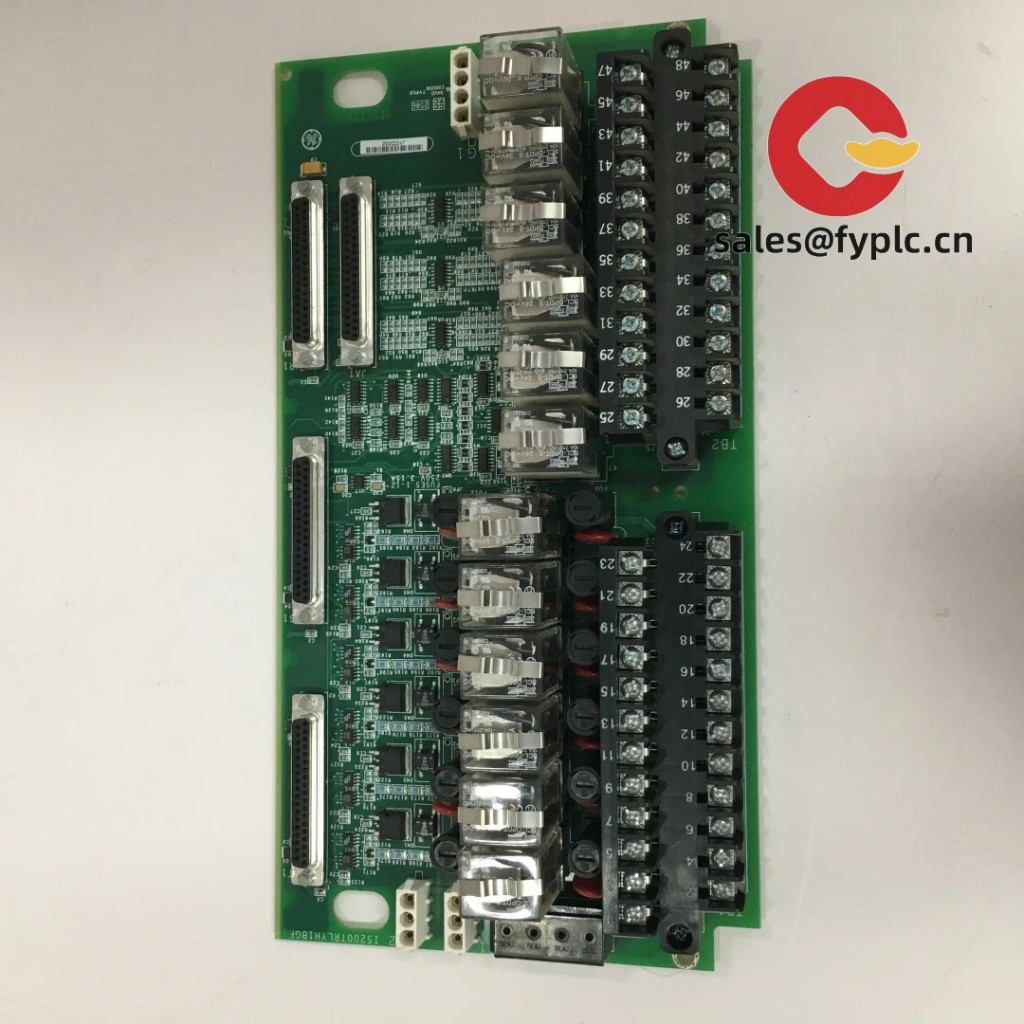

Rear view showing terminal blocks for analog inputs/outputs, digital I/O, and power supply

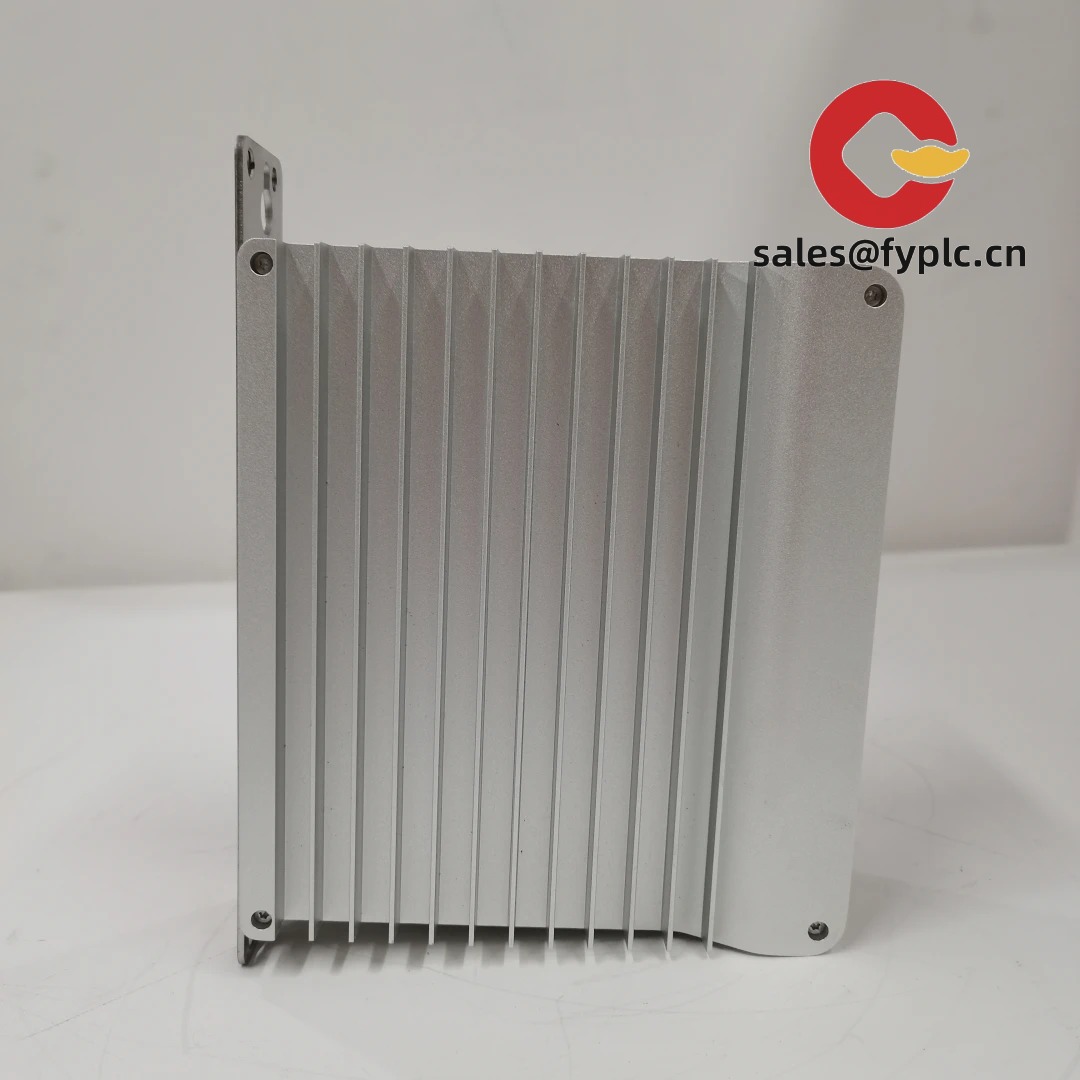

Typical rack-mount installation with recommended ventilation spacing

Reviews

There are no reviews yet.